Direct torque control method for non-salient pole type hybrid excitation motor for electric vehicle

A technology of hybrid excitation motor and direct torque control, which is applied in the direction of AC motor control, motor parameter estimation/correction, control system, etc., and can solve the problems of overall efficiency decrease and increase of motor armature resistance heat generation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further explained below in conjunction with the accompanying drawings.

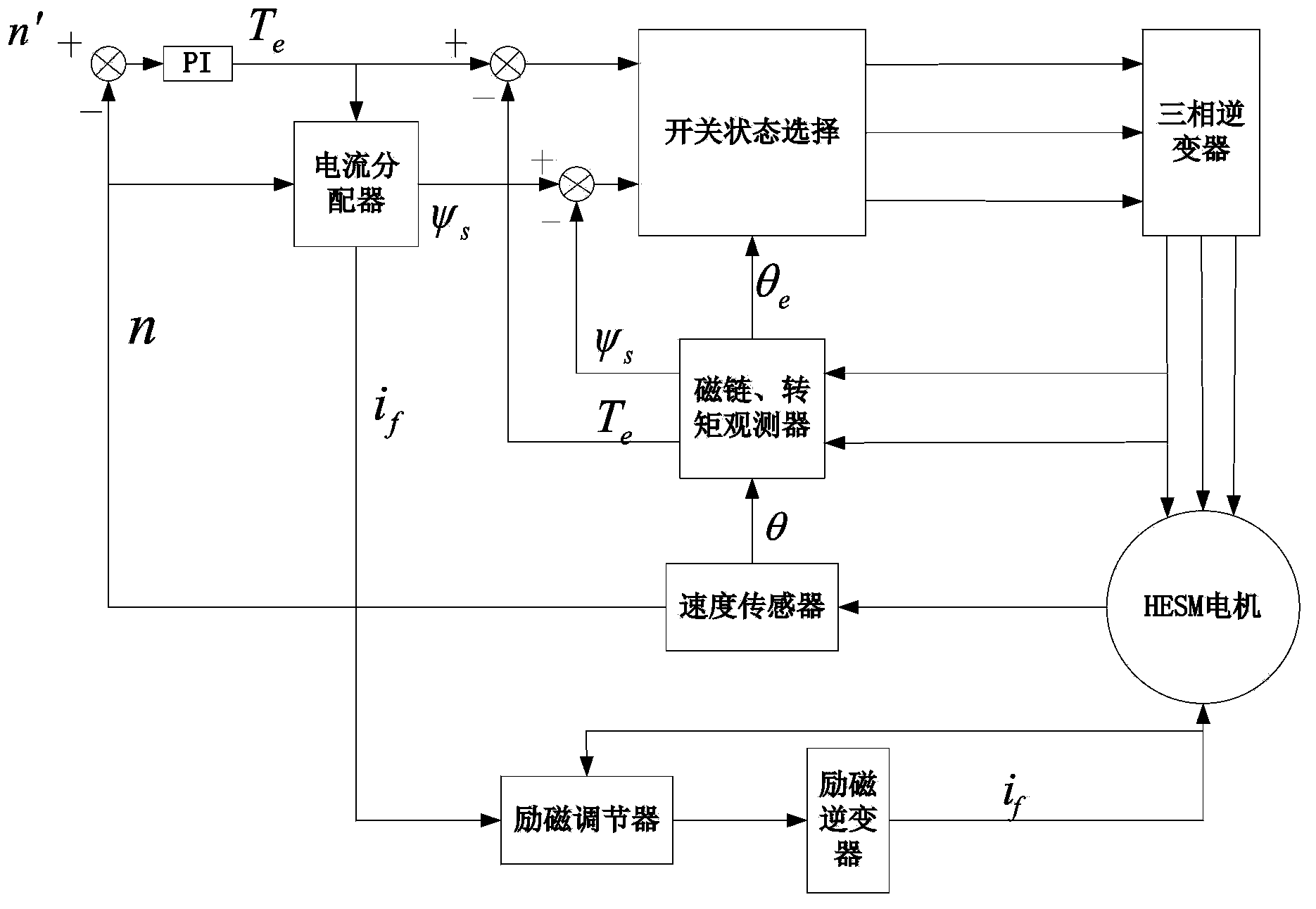

[0046] The control system based on the direct torque control method of the hidden pole type hybrid excitation motor for electric vehicles of the present invention is as follows: figure 2 Shown: The control system is composed of main circuit, detection circuit and control circuit. The main circuit is composed of a hidden pole hybrid excitation motor, a PWM inverter, a current distributor, an excitation regulator, and an excitation inverter; the detection circuit is composed of a voltage and current sensor and an incremental photoelectric encoder; the control circuit is composed of a DSP chip and its peripheral circuits.

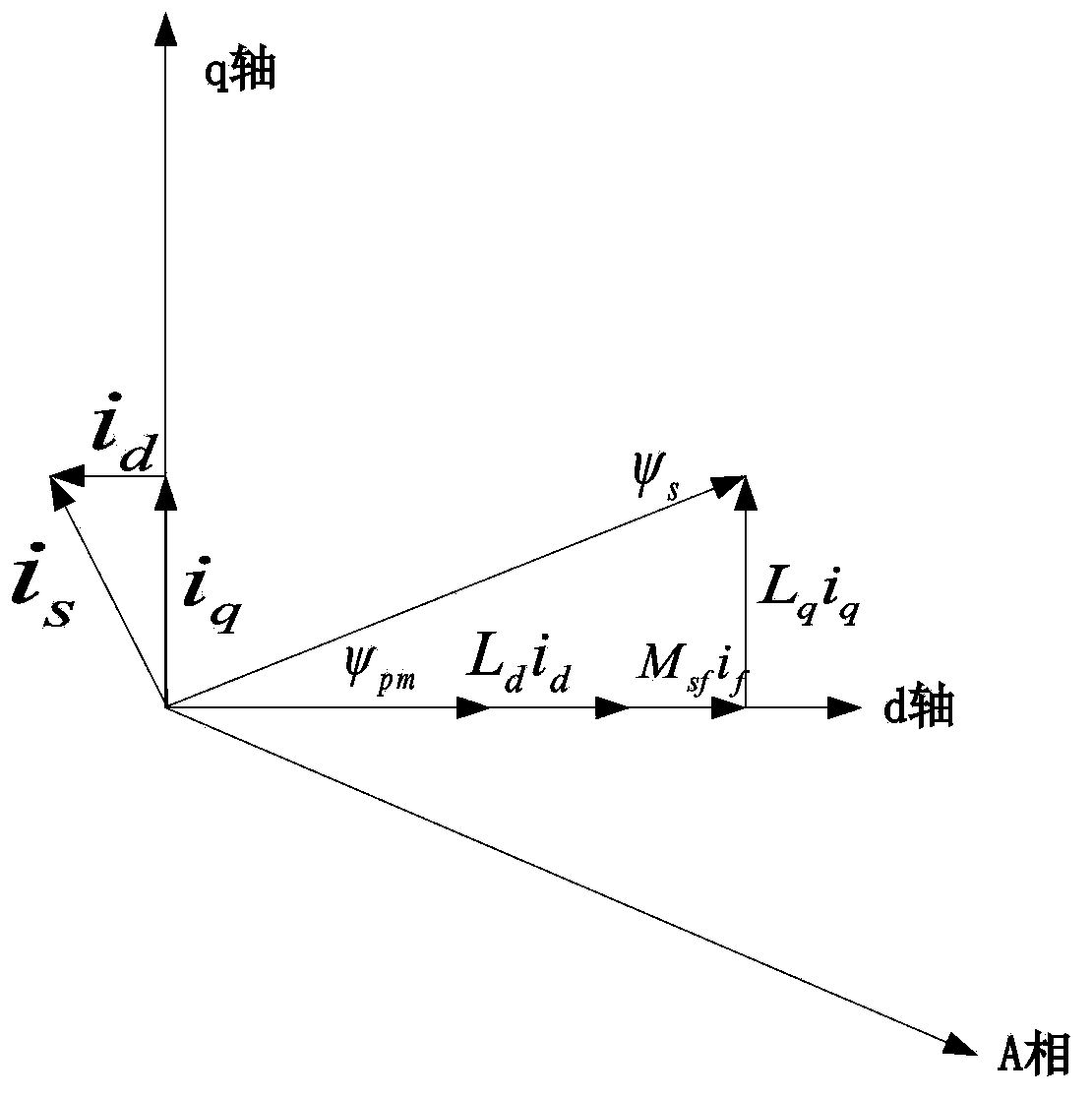

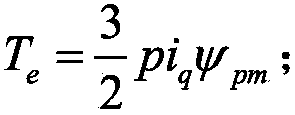

[0047] A direct torque control method for a hidden-pole hybrid excitation motor for an electric vehicle. A direct torque control strategy is adopted for a hidden-pole hybrid excitation motor: when the motor is in the low-speed standard area, the low-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com