Method for measuring size of MRI superconducting wire rod woven insulated wire rod by way of wire reel rewinding

A technology of superconducting wire rod and wire rod, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve the problem that the size cannot be truly reflected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Round NbTi wire size measurement

[0032] Proceed as follows:

[0033] Step 1: Take 1000m of braided insulated NbTi wire with a nominal diameter of 0.82mm. Clean the wire wheel and rewinder with clean water, dehydrate with absolute ethanol, and blow dry;

[0034] Step 2: Fix the reel of the wire to be tested on the winding spool, and clamp the positioning reel in the corresponding positioning hole of the reel so that the winding tension can be loaded normally.

[0035] Step 3: Put one end of the wire to be tested into the rewinding equipment, ensure that the wire is in the corresponding guide groove, receive it on the measuring wire wheel, and simply bend and fix it;

[0036] Step 4: Set the rewinding tension to 30N, start densely packed rewinding wires, and the rewinding speed is 50m / min;

[0037] Step 5: Start winding 2 to 3 times, artificially apply pressure to the wires to ensure the tightness between the wires, and apply lateral pressure with a PTFE rod after st...

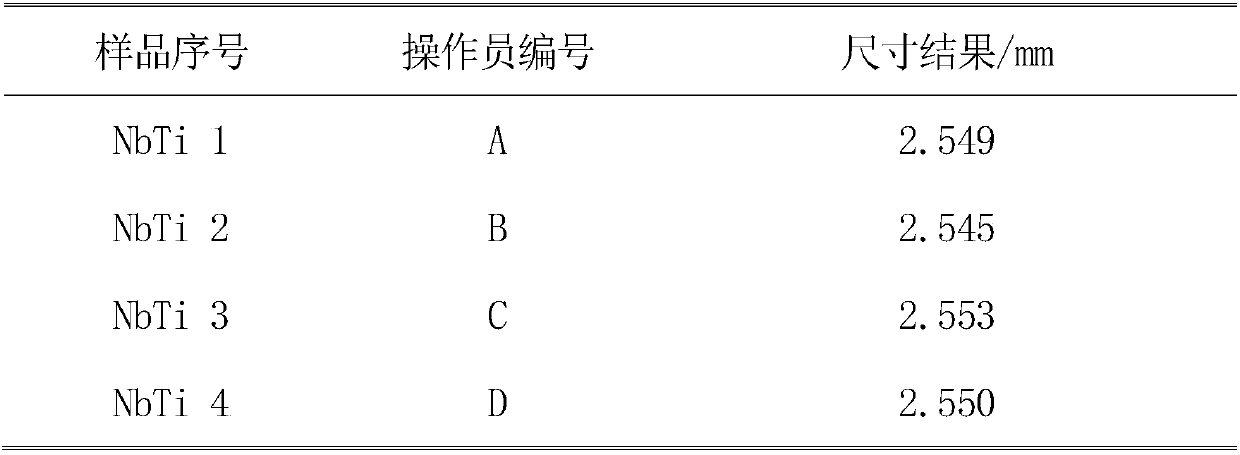

Embodiment 2

[0042] Embodiment 2: Rectangular NbTi wire rod size measurement

[0043] Step 1: Take a 500m braided insulated NbTi wire with a rectangular (width*height) nominal size of 2.25mm*1.45mm. Clean the wire wheel and rewinder with clean water, dehydrate with absolute ethanol, and blow dry;

[0044] Step 2: Fix the reel of the wire to be tested on the winding spool, and clamp the positioning reel in the corresponding positioning hole of the reel so that the winding tension can be loaded normally.

[0045] Step 3: Put one end of the wire to be tested into the rewinding equipment, ensure that the wire is in the corresponding guide groove, receive it on the measuring wire wheel, and simply bend and fix it;

[0046] Step 4: Set the rewinding tension to 25N, start densely packed rewinding wires, and the rewinding speed is 20m / min;

[0047] Step 5: Start winding 2 to 3 times, artificially apply pressure to the wires to ensure the tightness between the wires, and apply lateral pressure wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com