Worm gear carrying and feeding and discharging robot paw and application thereof

A robot and worm gear technology, applied in the field of robotic hands, can solve the problems of limiting the development of worm gear processing automation, low degree of worm gear processing automation, complex processing process, etc., to improve production quality and efficiency, meet automation requirements, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

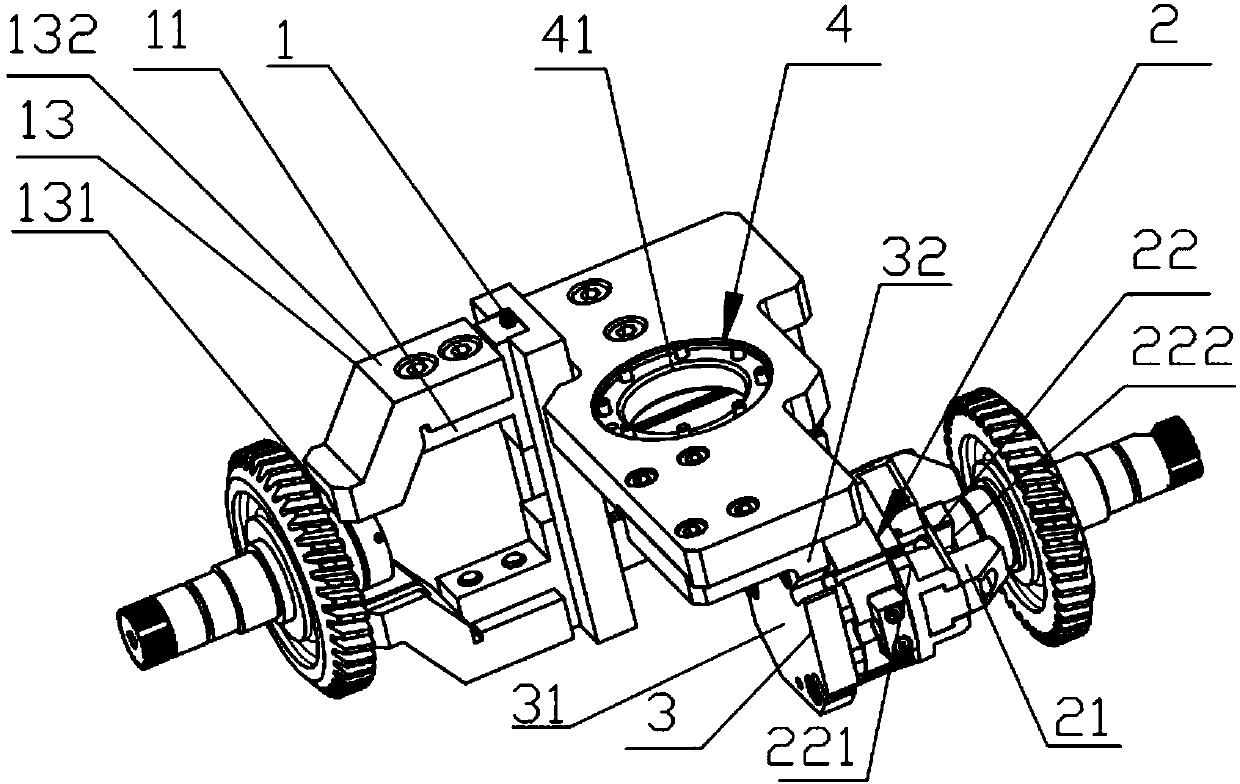

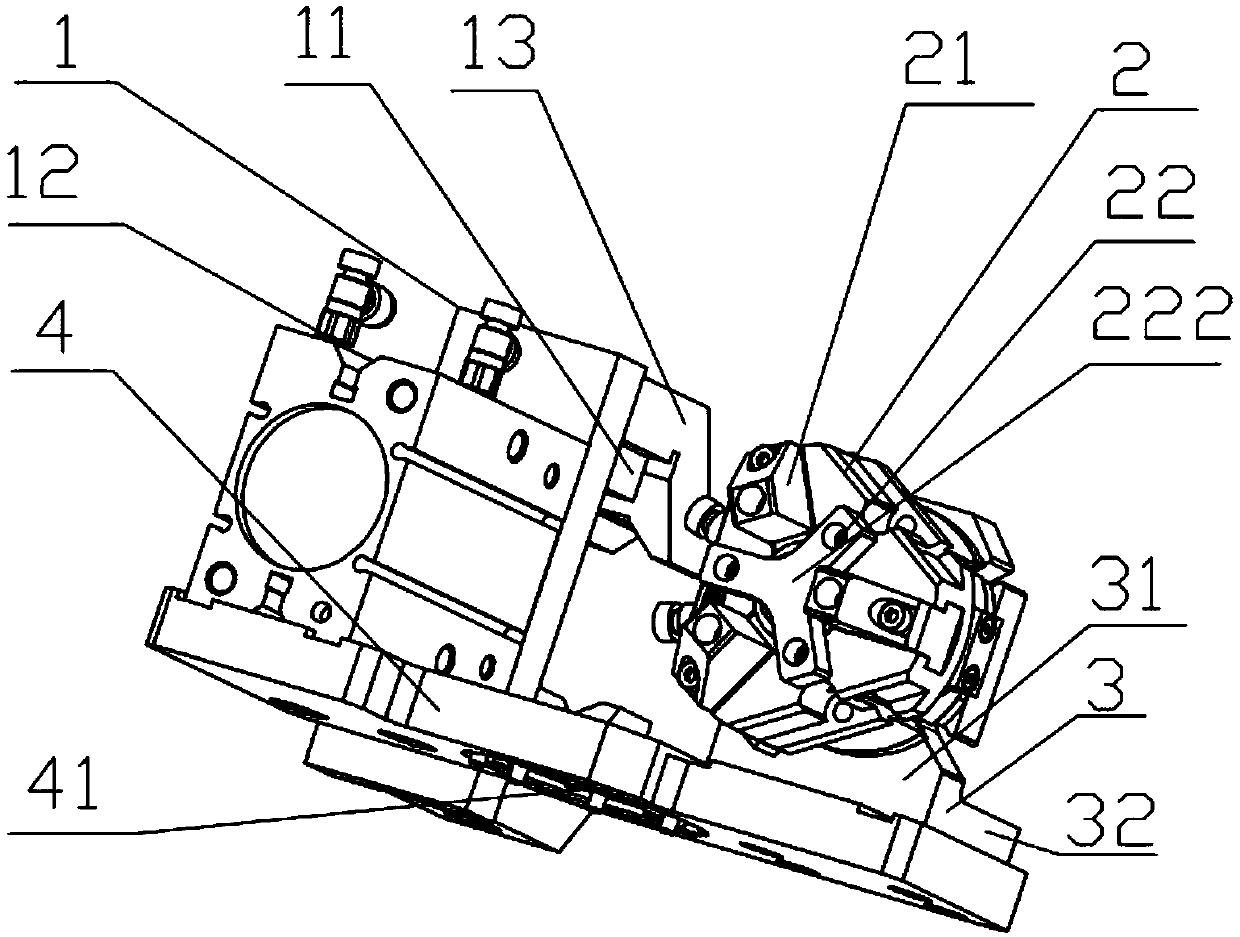

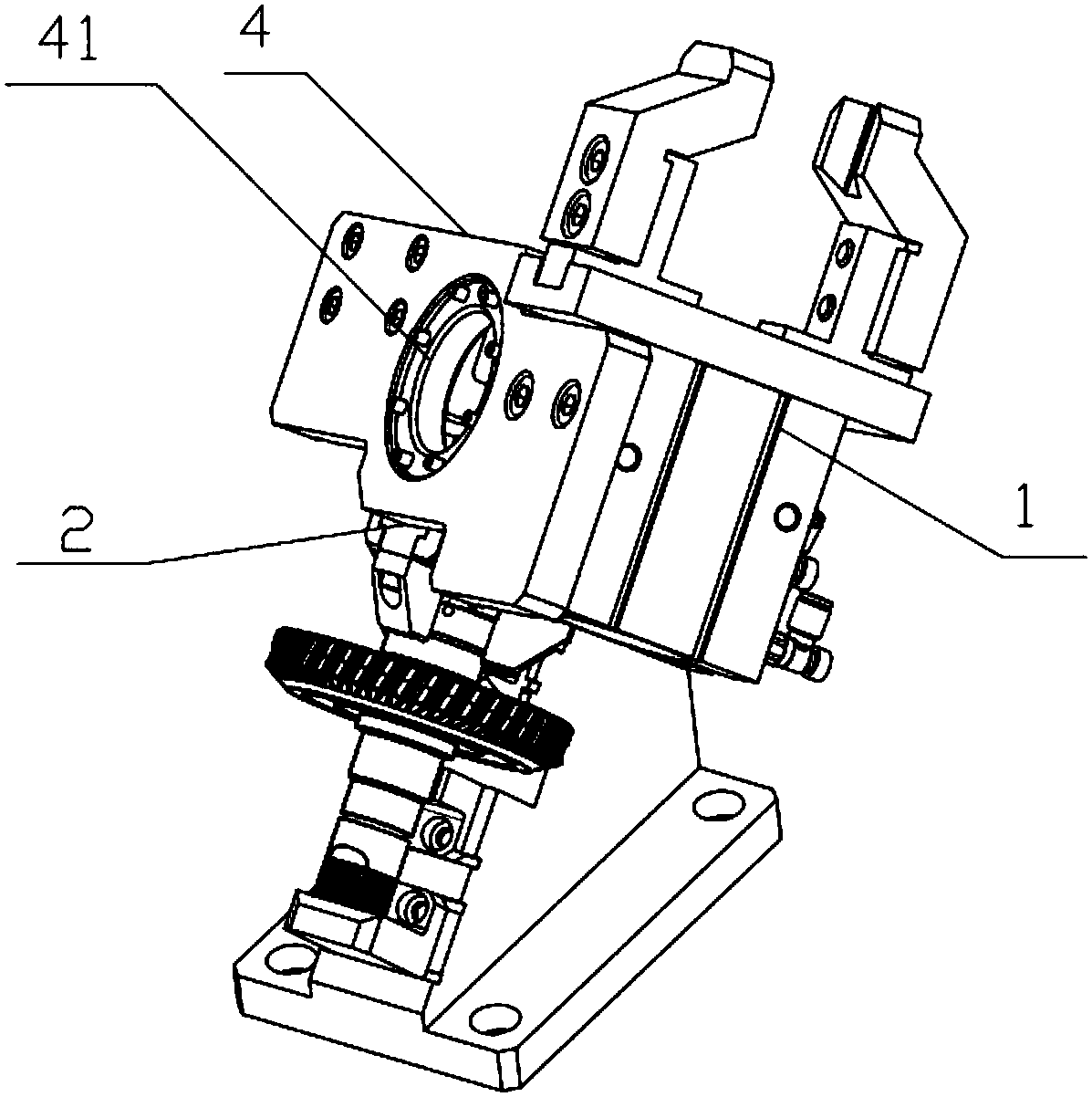

[0036] The invention provides a gripper of a worm gear handling and loading and unloading robot and an application thereof.

[0037] figure 1 It is a structural schematic diagram of a worm wheel handling and loading and unloading robot gripper in a preferred embodiment of the present invention; figure 2 It is a structural schematic diagram of a worm wheel handling and loading and unloading robot gripper in a preferred embodiment of the present invention; image 3 It is a schematic diagram of the feeding of the worm wheel handling and loading and unloading robot gripper in a preferred embodiment of the present invention; Figure 4 It is a schematic structural diagram of a pneumatic gripper in a preferred embodiment of the present invention; Figure 5 It is a structural schematic diagram of a pneumatic gripper clamping a worm wheel in a preferred embodiment of the present invention; Image 6 It is a structural schematic diagram of a pneumatic gripper clamping a worm wheel in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com