A kind of preparation method and application of silver iodide/bismuth selenate composite material

A composite material, silver iodide technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, oxidation preparation of carbonyl compounds, etc., can solve the problems of uncontrollable and many steps, achieve easy control, mild reaction conditions, and overcome the easy agglomeration of particles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

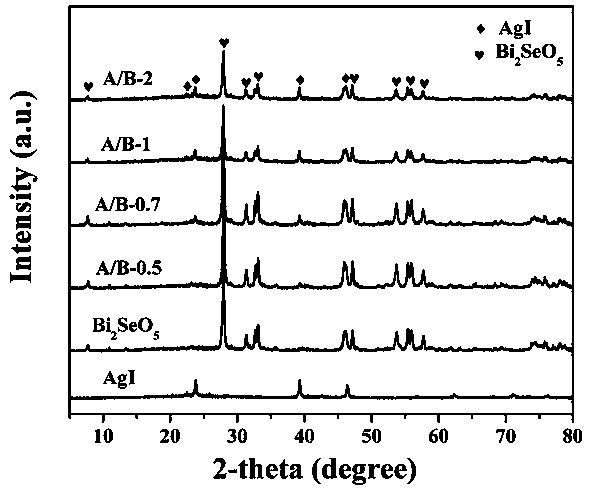

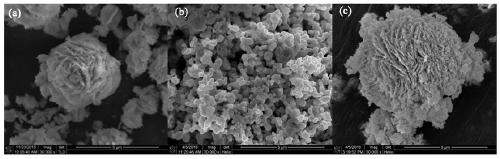

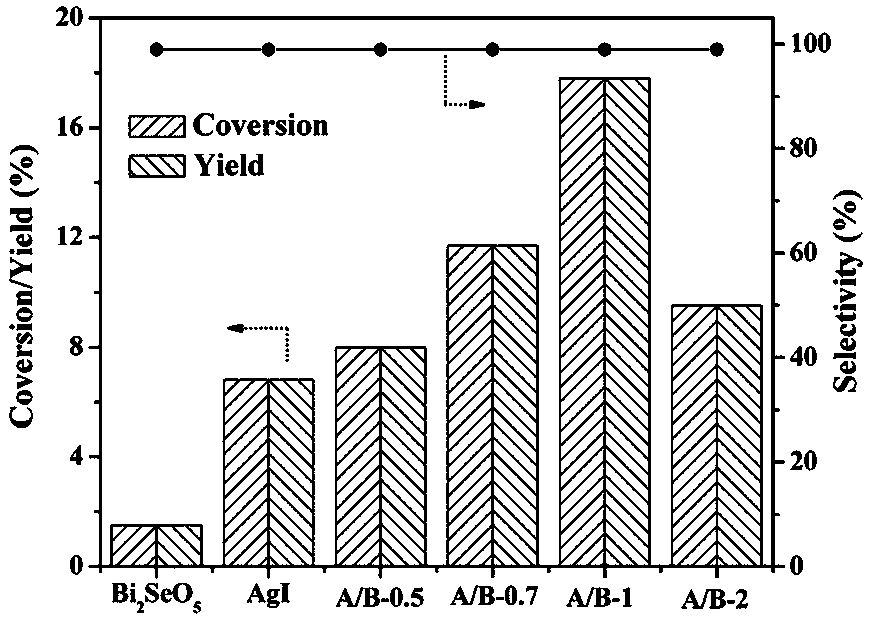

[0023] (1) Photocatalyst Bi 2 SeO 5 Preparation: 2 mmol of bismuth oxide, 3 mmol of selenium powder and 0.5 g of sodium borohydride were mixed evenly, placed in a muffle furnace, and calcined at 500 °C for 3 h in an air atmosphere.

[0024] (2) Composite photocatalyst AgI / Bi 2 SeO 5 Preparation: AgI / Bi with a molar percentage of AgI of 0.5% was prepared by in-situ deposition method 2 SeO 5 Complex, weigh 0.40 mmol Bi 2 SeO 5 The powder was dispersed in 25 mL of deionized water, and then 10 mL of AgNO was added to the resulting solution 3 solution (containing 2 μmol AgNO 3 ); stirred in the dark for 30 min, then added dropwise 25 mL of a solution containing 2 μmol KI until the solution turned bright yellow; centrifuged, washed the precipitate with distilled water and absolute ethanol, and dried in vacuum at 60 °C for 2 h to obtain AgI / Bi 2 SeO 5 Composite precursor; the resulting precursor can be calcined at 200 ℃ for 0.5 h in a nitrogen-hydrogen mixture with a hydrog...

Embodiment 2

[0026](1) Photocatalyst Bi 2 SeO 5 Preparation: 2 mmol of bismuth oxide, 3 mmol of selenium powder and 0.5 g of sodium borohydride were mixed evenly, placed in a muffle furnace, and calcined at 500 °C for 3 h in an air atmosphere.

[0027] (2) Composite photocatalyst AgI / Bi 2 SeO 5 Preparation: AgI / Bi with a molar percentage of AgI of 0.7% was prepared by in-situ deposition method 2 SeO 5 Complex, weigh 0.40 mmol Bi 2 SeO 5 The powder was dispersed in 25 mL of deionized water, and then 10 mL of AgNO was added to the resulting solution 3 solution (containing 2.8 μmol AgNO 3 ); stirred in the dark for 30 min, then added 25 mL of a solution containing 2.8 μmol KI dropwise until the solution turned bright yellow; centrifuged, washed the precipitate with distilled water and absolute ethanol, and dried in vacuum at 60 °C for 2 h to obtain AgI / Bi 2 SeO 5 Composite precursor; the resulting precursor can be calcined at 500 ℃ for 0.5 h in a nitrogen-hydrogen mixture with a hyd...

Embodiment 3

[0029] (1) Photocatalyst Bi 2 SeO 5 Preparation: 2 mmol of bismuth oxide, 3 mmol of selenium powder and 0.5 g of sodium borohydride were mixed evenly, placed in a muffle furnace, and calcined at 500 °C for 3 h in an air atmosphere.

[0030] (2) Composite photocatalyst AgI / Bi 2 SeO 5 Preparation: AgI / Bi with a molar percentage of AgI of 1% was prepared by in-situ deposition 2 SeO 5 Complex, weigh 0.40 mmol Bi 2 SeO 5 The powder was dispersed in 25 mL of deionized water, and then 10 mL of AgNO was added to the resulting solution 3 solution (containing 4 μmol AgNO 3 ); stirred in the dark for 30 min, then added 25 mL of a solution containing 4 μmol KI dropwise until the solution turned bright yellow; centrifuged, washed the precipitate with distilled water and absolute ethanol, and dried in vacuum at 60 °C for 2 h to obtain AgI / Bi 2 SeO 5 Composite precursor; the resulting precursor can be calcined at 300 ℃ for 4 h in a nitrogen-hydrogen mixture with a hydrogen content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com