A forming and processing method for preparing cross-linked polymer materials

A technology of high molecular polymers and polymer materials, which is applied in the field of material processing and can solve problems such as reprocessing and molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

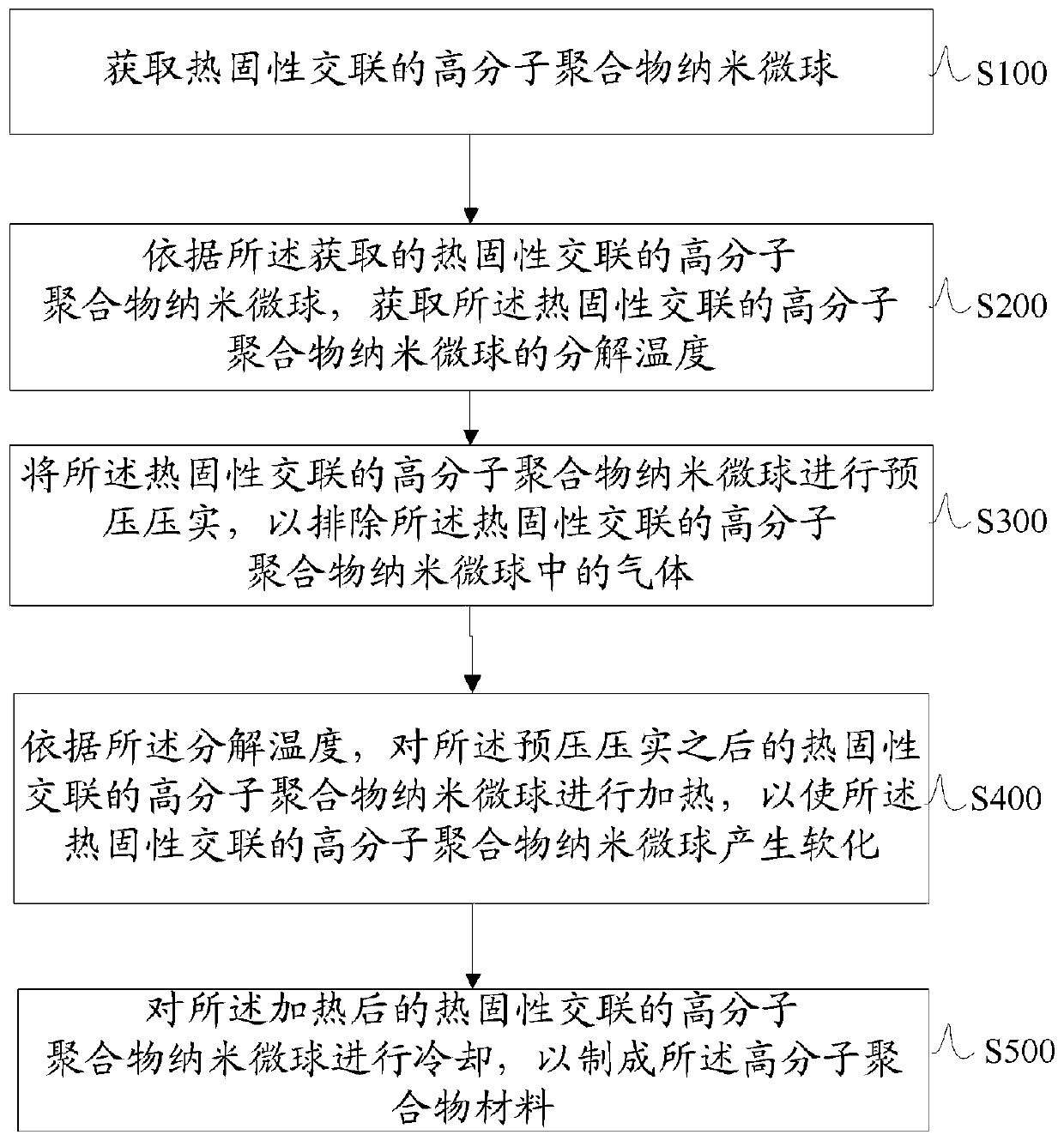

[0020] The present invention discloses that the present invention provides a forming and processing method for preparing cross-linked high molecular polymer materials. The decomposition temperature of the ball; then the thermosetting crosslinked polymer nanospheres are pre-compacted to get rid of the gas in the thermosetting crosslinked polymer nanospheres; then according to the decomposition temperature, the The thermosetting cross-linked polymer nanospheres after the pre-compression are heated to soften the thermosetting cross-linked polymer nanospheres; then the softened thermosetting cross-linked polymers The polymer nano microspheres are cooled, and then the high molecular polymer material is produced. After the thermosetting cross-linked polymer is prepared into nano-sized high-strength microspheres, there are electrostatic repulsion, van der Waals force and volume repulsion among the high-strength microsphere particles, so that the dispersed emulsion of the polymer can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com