Parallel channel membrane and parallel channel membrane assembly

A parallel channel and channel membrane technology, applied in the field of water treatment, can solve the problems of large size of integrated equipment, serious pollution of membrane filaments, small filling area, etc., achieve high processing capacity, avoid sludge accumulation, and high filling density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

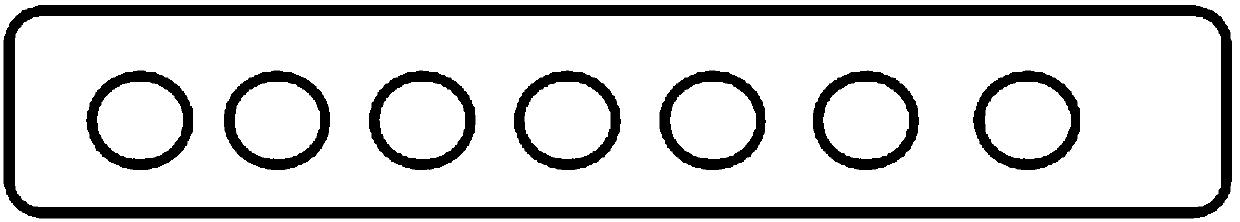

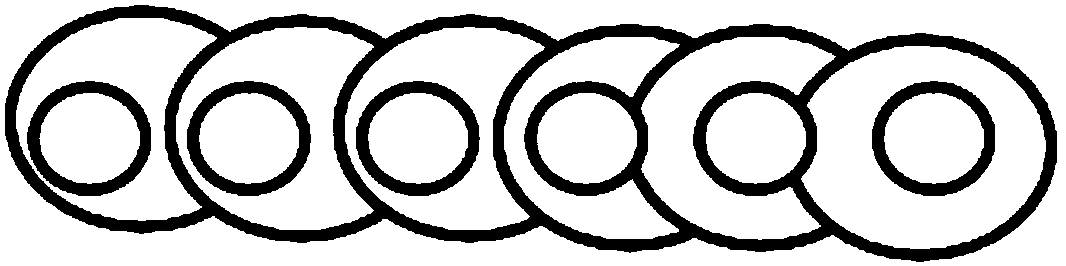

[0016] Parallel channel membranes such as Figure 1-2 As shown, a plurality of cylindrical channels are arranged in parallel along the same plane, and the plurality of cylindrical channels are wrapped around the outer wall of the separation layer. The number of the plurality of cylindrical channels is 4-10. The cross-sectional outer periphery of the parallel channel membrane is made of straight lines (see figure 1 ) or composed of a round continuous curve with a periodic concave-convex structure (see figure 2 ).

[0017] The parallel channel film is produced through an extrusion die with parallel core liquid (gas) tubes and a common solution (or melt) flow channel outlet. The so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com