Flotation machine filter device

A technology of filtering device and flotation machine, which is applied in the directions of flotation, filtration and separation, fixed filter element filter, etc., can solve the problems of inability to timely and accurately control the liquid level, large adjustment error, large liquid level fluctuation, etc. To achieve the effect of simple structure, long service life and small fluctuation of liquid level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

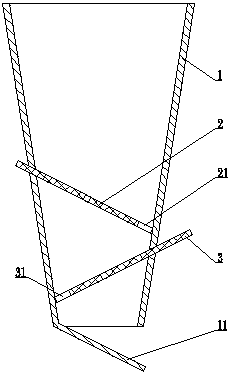

[0007] see figure 1 , the present invention comprises a conical filter cartridge 1, a left inserting plate 2 and a right inserting plate 3, a baffle 11 is provided under the left side plate of the conical filter cartridge 1, and the baffle 11 is arranged on a conical Below the lower opening of the filter cartridge 1, a right notch 21 is provided on the right side of the left board 2, and a left notch 31 is provided on the left side of the right board 3. plate, the right inserting plate 3 is a slanted plate with a low left and a high right, on the left side plate of the conical filter cartridge 1 there is a sloping opening I with a high left and a low right and matching the size of the left inserting plate 2, On the right side plate of the conical filter cartridge 1, there is a slanted opening II with a low left and a high right and is adapted to the size of the right inserting plate 3. The left inserting plate 2 is inserted into the inclined opening I, and the right inserting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com