Rotary injection desulfurization spray guns suitable for different types of hot metal tanks or different desulfurizers

A technology of rotary blowing and desulfurization spray gun, applied in the field of molten iron pretreatment, can solve the problems of spray gun vibration critical spray flow rate, low utilization rate of desulfurization agent, low magnesium spray intensity, etc., so as to reduce liquid level fluctuation and splash, The effect of shortening mixing time, improving high temperature resistance and thermal shock crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

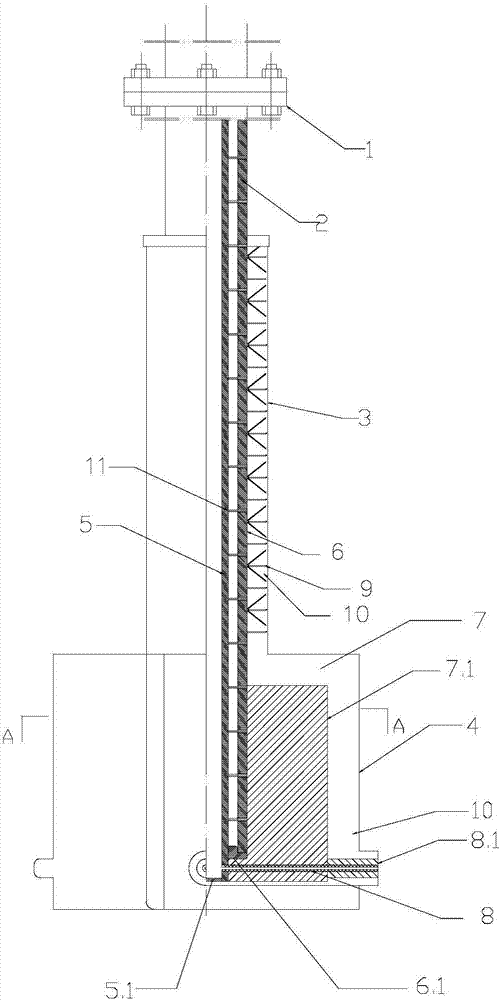

[0043] Such as Figure 1~2 As shown, a rotary injection desulfurization spray gun suitable for different types of molten iron tanks or different desulfurizers, including a connecting flange 1, a connecting section spray gun body 2, a gun body section spray gun body 3 and a spray gun section 4, a connecting section spray gun body 2, Spray gun body 3 and spray gun section 4 from the inside to the outside are the main pipe 5 and the reinforcing pipe 6 in sequence. The outer side of the main pipe 5 takes the axis as the center line and is evenly arranged in a radial shape from the inside to the outside. There are a number of bridge welding for connecting the reinforcing pipe 6 part 11, and pass through the opening on the reinforcing pipe 6, four rotating blades 7 are symmetrically arranged on the main pipe 5 of the spray gun section 4 and the outer wall of the reinforcing pipe 6, and the rotating blade 7 includes a blade metal core 7.1, and the side of the bottom of the main pipe 5...

Embodiment 2

[0062] This embodiment is basically the same as Embodiment 1, except that the number of rotating blades 7 and interpolated nozzles 8 of the rotating spray gun is three.

Embodiment 3

[0064] This embodiment is basically the same as Embodiment 1, except that the number of rotating blades 7 and interpolated nozzles 8 of the rotating spray gun is two.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com