Automated guided vehicle (AGV) base structure and AGV

A technology of bottom plate and hinged seat, which is applied in the direction of substructure, motor vehicles, vehicle parts, etc., can solve the problems of spring bending, reduce the structural stability and service life of AGV chassis, and poor sensitivity, so as to increase the distance and simplify the AGV chassis structure, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

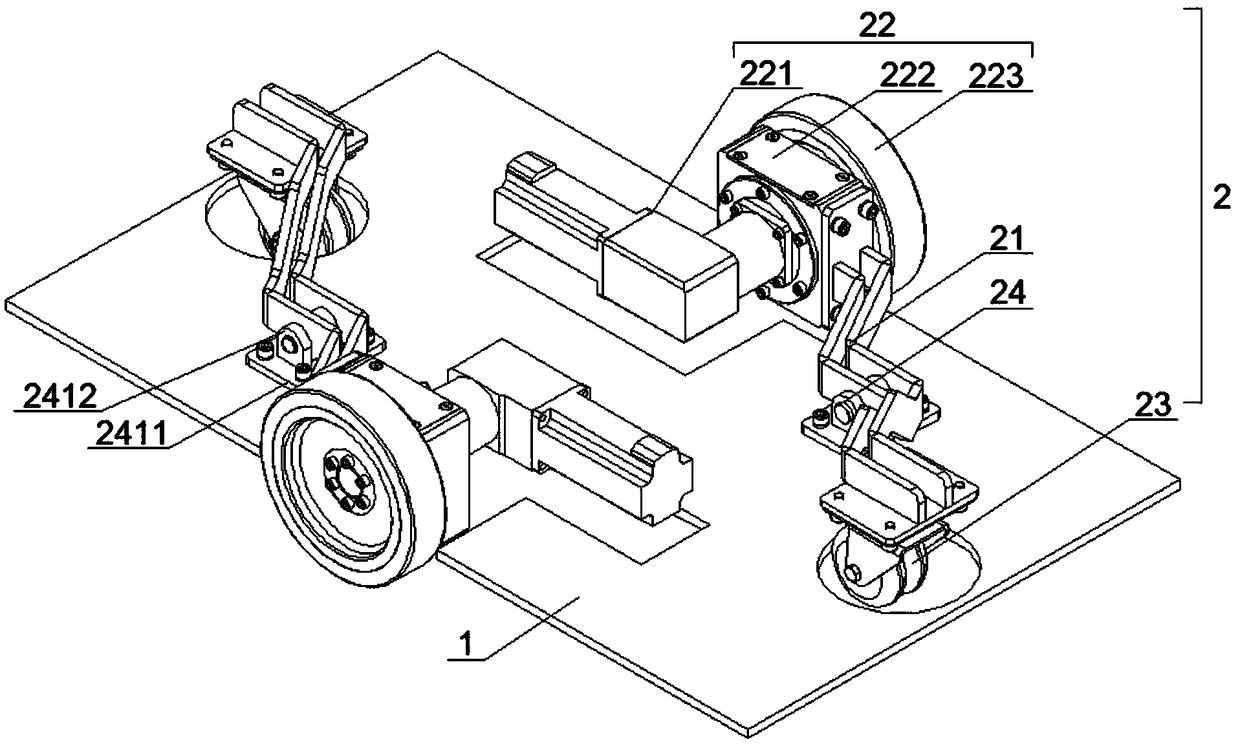

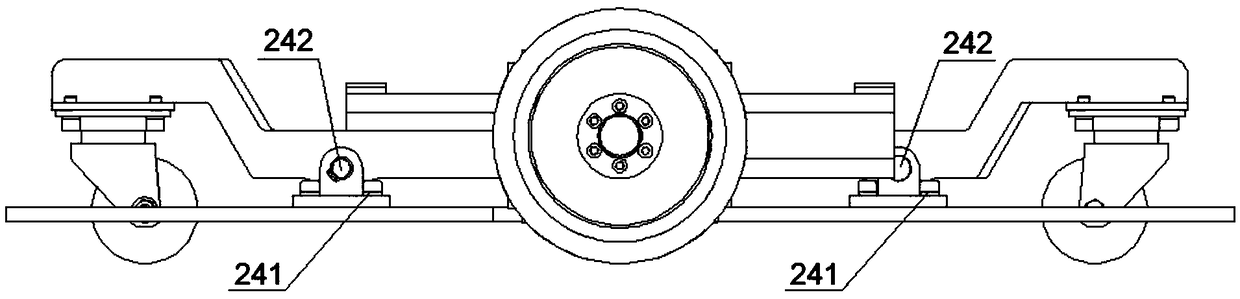

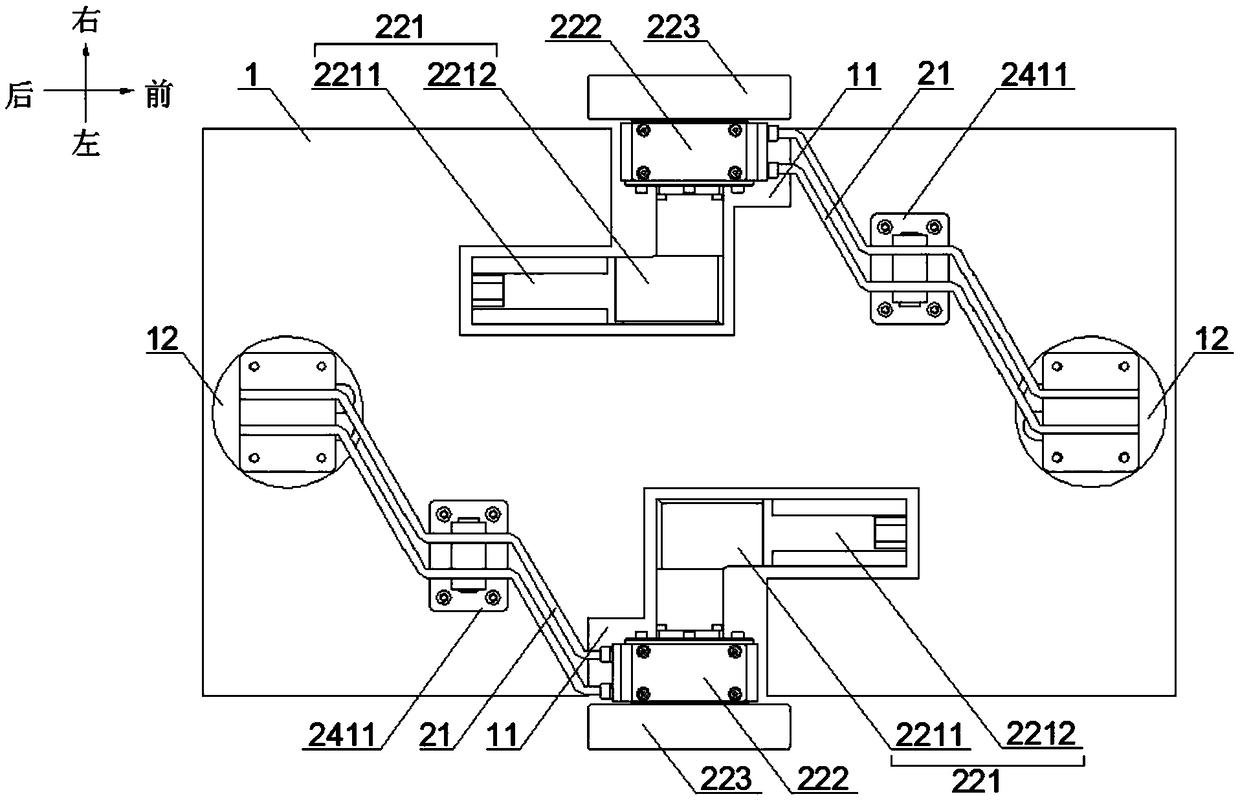

[0034] see figure 1 , an AGV base structure, including a base plate and two floating devices 2, the two floating devices 2 are fixed on opposite sides of the base plate 1; each floating device 2 includes a lever arm 21, a driving device 22, a universal wheel 23 and The hinged support assembly 24, one end of the lever arm 21 is fixed on the drive device 22, the other end of the lever arm 21 is fixed with a universal wheel 23, and the middle part of the lever arm 21 is floatingly fixed on the base plate 1 through the hinged support assembly 24.

[0035] Compared with the traditional six-wheel AGV chassis, the two floating devices 2 can be centrally symmetrical and horizontally distributed on the opposite sides of the base plate 1, which can simplify the AGV chassis structure and reduce costs. The driving devices 22 in the two floating devices 2 can provide Sufficient driving power, each articulated support assembly 24 facilitates the lever arm 21 to float up and down with the un...

Embodiment 2

[0061] An AGV vehicle includes the AVG chassis structure provided in any one of the first embodiments, and the AVG chassis structure will not be described here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com