Freeze-dried block of probiotics and its preparation method, as well as instant fruit cereal oatmeal based on the freeze-dried block and its preparation method

A probiotics and freeze-drying technology, applied in the direction of bacteria, food science, Lactobacillus, etc. used in food preparation, can solve the problems of rare, pure natural freeze-dried fruits, etc., to reduce blood sugar, blood lipids, cholesterol, enhance integrity Sexual and structural strength, effect on promoting gastrointestinal motility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

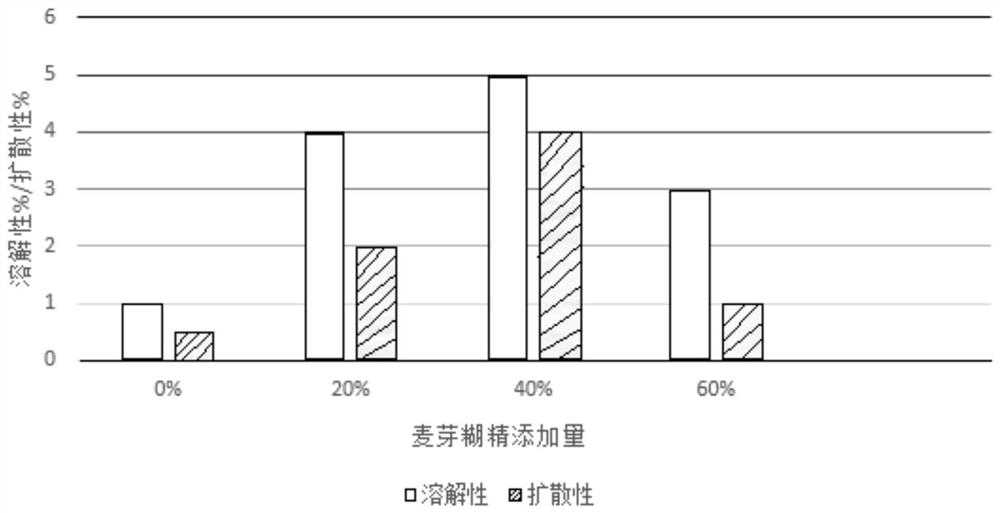

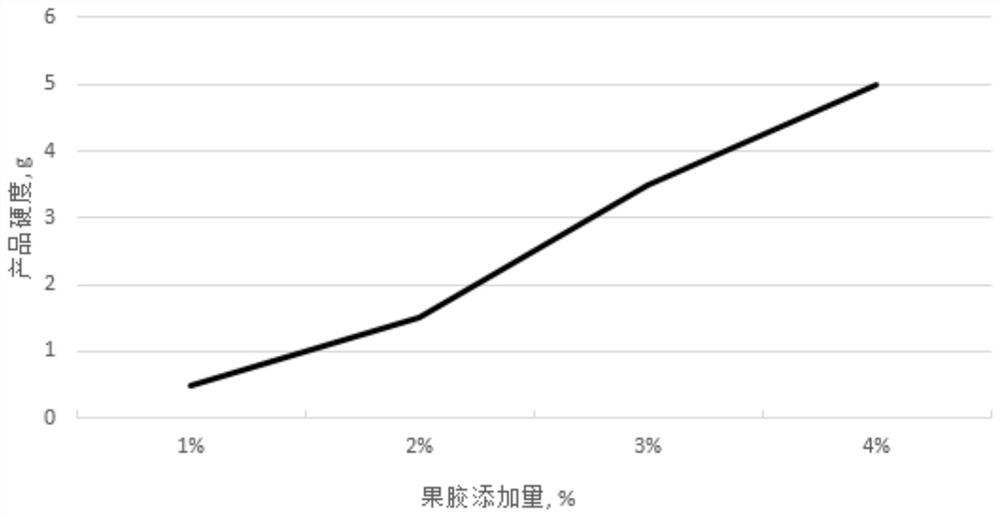

[0047] A freeze-dried block of probiotics, comprising: 40% maltodextrin, 48.95% white sugar, 1% pectin, 0.05% probiotic powder and 10% concentrated fruit and vegetable juice by mass percentage;

[0048] The preparation method of the above probiotic freeze-dried block is to add hot water at 60°C to the sugar tank, turn on the stirring mode, and at the same time mix white sugar, maltodextrin and pectin evenly, transfer to the sugar tank, and stir until white The sugar, maltodextrin and pectin are completely dissolved to obtain a mixed liquid, and the mixed liquid is homogenized. Dilute the concentrated fruit and vegetable juice to a mass concentration of 20%, then add the diluted fruit and vegetable concentrated juice to the homogenized mixture, then add probiotic powder at room temperature, stir evenly, transfer to a mold, and freeze Afterwards, freeze-drying is carried out in the vacuum freeze-drying machine. The specific process of freeze-drying is: turn on the refrigeration ...

Embodiment 2

[0063] A freeze-dried block of probiotics, comprising: 48.95% of maltodextrin, 40% of white sugar, 2% of pectin, 0.05% of probiotic powder and 9% of concentrated fruit and vegetable juice by mass percentage;

[0064] The preparation method of the above probiotic freeze-dried block is to add hot water at 60°C to the sugar tank, turn on the stirring mode, and at the same time mix white sugar, maltodextrin and pectin evenly, transfer to the sugar tank, and stir until white The sugar, maltodextrin and pectin are completely dissolved to obtain a mixed liquid, and the mixed liquid is homogenized. Dilute the concentrated fruit and vegetable juice to a mass concentration of 25%, then add the diluted fruit and vegetable concentrated juice to the homogenized mixture, then add probiotic powder at room temperature, stir evenly, transfer to a mold, and freeze Then freeze-dry in the vacuum freeze-drying machine. The specific process of freeze-drying is: turn on the refrigeration compressor ...

Embodiment 3

[0079] A probiotic freeze-dried block, by mass percentage, comprising: 44% maltodextrin, 47.9% white sugar, 3% pectin, 0.1% probiotic powder and 5% fruit and vegetable concentrated juice;

[0080] The preparation method of the above probiotic freeze-dried block is to add hot water at 60°C to the sugar tank, turn on the stirring mode, and at the same time mix white sugar, maltodextrin and pectin evenly, transfer to the sugar tank, and stir until white The sugar, maltodextrin and pectin are completely dissolved to obtain a mixed liquid, and the mixed liquid is homogenized. Dilute the concentrated fruit and vegetable juice to a mass concentration of 30%, then add the diluted fruit and vegetable concentrated juice to the homogenized mixture, then add probiotic powder at room temperature, stir evenly, transfer to a mold, and freeze Then freeze-dry in the vacuum freeze-drying machine. The specific process of freeze-drying is: turn on the refrigeration compressor of the vacuum freeze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com