An integrated monitoring system for industrial equipment based on edge computing

An industrial equipment and edge computing technology, applied in the field of computer communication, can solve the problems of increasing the processing pressure of the cloud data center by the upload of monitoring data, the inability to monitor the industrial equipment at the same time, and the increase of the delay of data transmission, so as to reduce the cost of labor operation and maintenance, weaken the Convergence effect, network loop reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

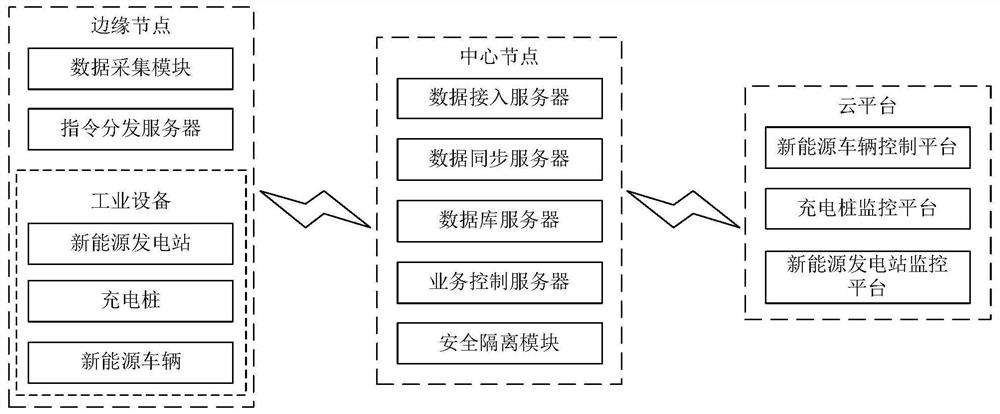

[0034] Such as figure 1 As shown, an integrated monitoring system for industrial equipment based on edge computing includes: cloud platform, central node and edge node.

[0035] The cloud platform is used for centralized storage of monitoring data of industrial equipment and output of core control instructions of industrial equipment. The core control instructions can be but not limited to modification instructions of important settings of edge nodes and central nodes and processing instructions of important data.

[0036] The central node is connected to the cloud platform by communication, and is used to receive the core control instructions output by the cloud platform, the synchronous processing of the monitoring data of industrial equipment, the pre-storage of monitoring data of industrial equipment, and the monitoring data of pre-stored industrial equipment Real-time processing and output of control commands.

[0037] The edge node is connected to the central node by co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com