Built-in permanent magnet synchronous motor for kart

A permanent magnet synchronous motor, built-in technology, applied to synchronous machines, synchronous motors with stationary armatures and rotating magnets, synchronous machine parts, etc., can solve the problem of high torque fluctuation standards and poor rotor structure design Reasonable, weaken the motor torque fluctuation and other problems, to achieve the effect of optimizing the working characteristics, reducing weight and reducing torque ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

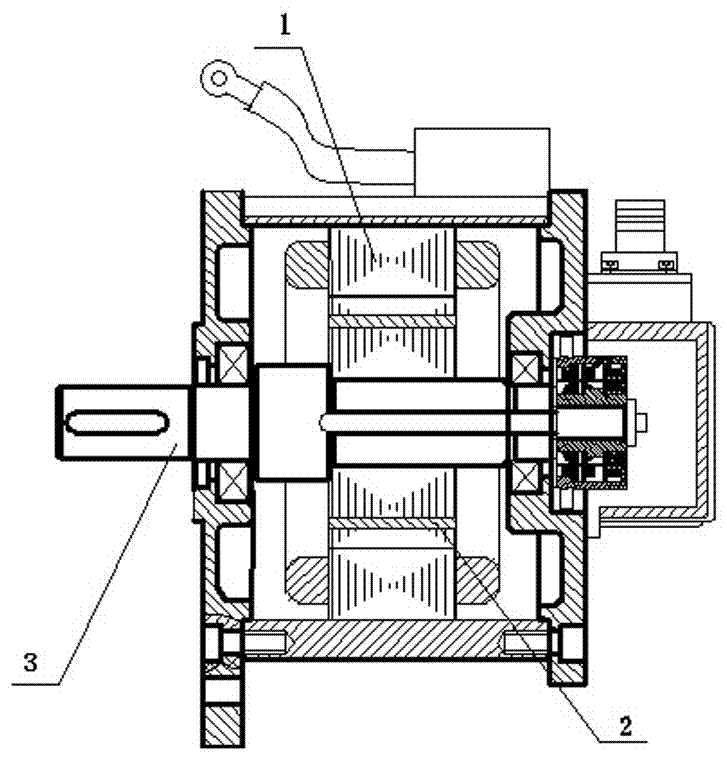

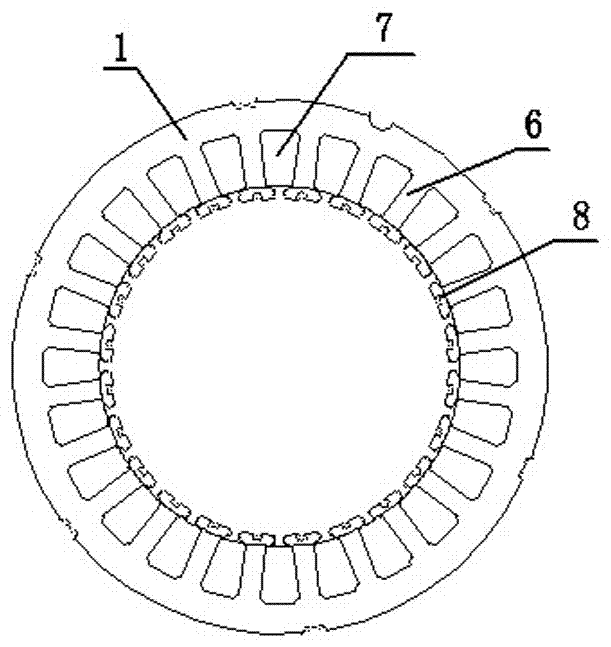

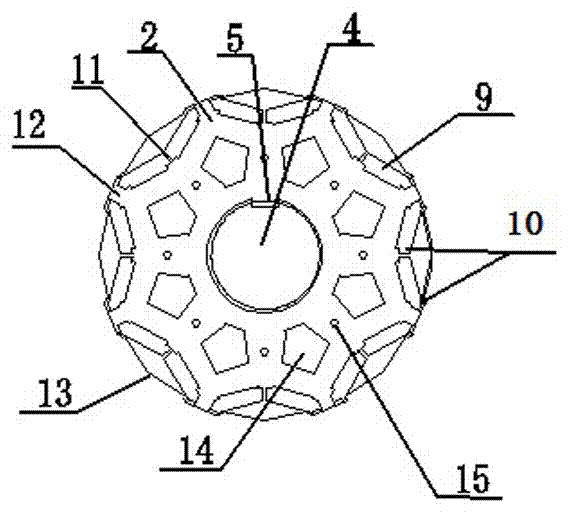

[0032] Such as Figure 1~3 A built-in permanent magnet synchronous motor for karts is shown, including a stator core, a rotor core and a rotor shaft. The stator core is sleeved on the outside of the rotor core, and the rotor core is sleeved on the outside of the rotor shaft. The stator core It is made of laminated silicon steel sheets, and the rotor core is made of laminated silicon steel sheets; the rotor core includes a shaft hole in the center, and the side wall of the shaft hole is provided with a keyway matching the rotor shaft flat key. The stator core is equipped with 24 stator teeth, and stator slots are formed between adjacent stator teeth. The stator teeth and stator slots have a symmetrical structure in the radial direction. The end of the stator teeth facing the rotor is the tooth end of the stator teeth, and the stator teeth The central part of the tooth end is provided with an arched virtual groove. The rotor iron core is provided with 4 opposite V-shaped magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com