Processing system and processing technology of waste lead-acid storage battery and application of regenerated lead

A lead-acid battery and processing system technology, applied in the field of electrochemistry, can solve the problems of inability to recycle, complex operation, etc., and achieve the effects of high production efficiency, serious pollution reduction, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

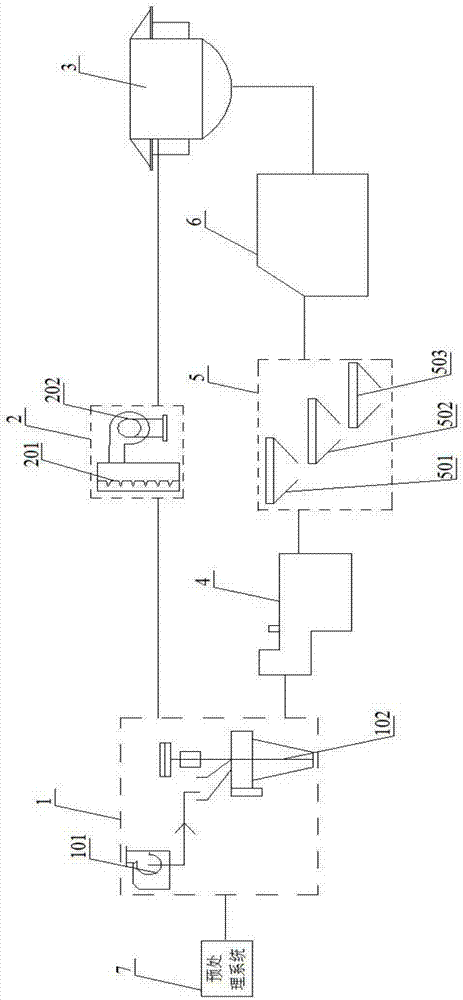

[0034] A waste lead-acid battery processing system, the system includes a crushing and sorting system 1, a drying system 2 connected to the crushing and sorting system through a grid conveying pipeline, and a lead melting pot 3 connected to the drying system 2 through a conveying pipeline; It also includes the smelting system 4 connected to the crushing and sorting system through the lead paste conveying pipeline, the lead scum removal system 5 connected to the smelting system 4 through the conveying pipeline, and the dust collection system connected to the lead scum removing system through the conveying pipeline. System 6, the dust collection system 6 communicates with the lead melting pot 3 through a delivery pipeline. Wherein said drying system is also communicated with hot air blower 202;

[0035] The system also includes a pretreatment system 7 before the crushing and sorting system, which pretreats the collected waste lead-acid batteries and then enters the crushing and ...

Embodiment 2

[0039] The process for treating waste lead-acid batteries by using the above-mentioned waste lead-acid batteries comprises the following steps:

[0040] (1) Recycle waste lead-acid batteries for pretreatment; recycle the waste acid in the lead-acid batteries into the waste acid tank, and recycle the clapboard;

[0041] (2) Use the crushing and sorting system to process the waste lead-acid batteries after step (1) pretreatment: the waste lead-acid battery materials after step (1) pretreatment enter the crusher through the feeding port on the upper part of the crusher After the crushing is completed, the material is discharged, and then enters the hydraulic grading box. According to the density of the material, it is gradually classified through multi-stage conversion under the action of water to obtain lead paste, grid and plastic respectively;

[0042] (3) transporting the grid separated from the step (2) to the drying furnace of the drying system through the grid conveying pipe...

Embodiment 3

[0048] Utilize the waste and used lead-acid storage battery processing system described in embodiment 1 to process the technology of waste and used lead-acid storage battery, comprise the following steps:

[0049] (1) Recycle the waste lead-acid battery for pretreatment; the waste acid in the waste lead-acid battery is recycled into the waste acid tank, and the partitions therein are recycled and reused;

[0050] (2) Use the crushing and sorting system to process the waste lead-acid batteries after step (1) pretreatment: the waste lead-acid battery materials after step (1) pretreatment enter the crusher through the feeding port on the upper part of the crusher After the crushing is completed, the material is discharged, and then enters the hydraulic grading box. According to the density of the material, it is gradually classified through multi-stage conversion under the action of water to obtain lead paste, grid and plastic respectively;

[0051] (3) Transport the grid obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com