Circuit used for prolonging service life of lead-acid storage batteries or battery packs

A lead-acid battery, battery pack technology, applied in lead-acid battery, lead-acid battery construction, battery circuit device and other directions, can solve problems such as low specific energy and short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

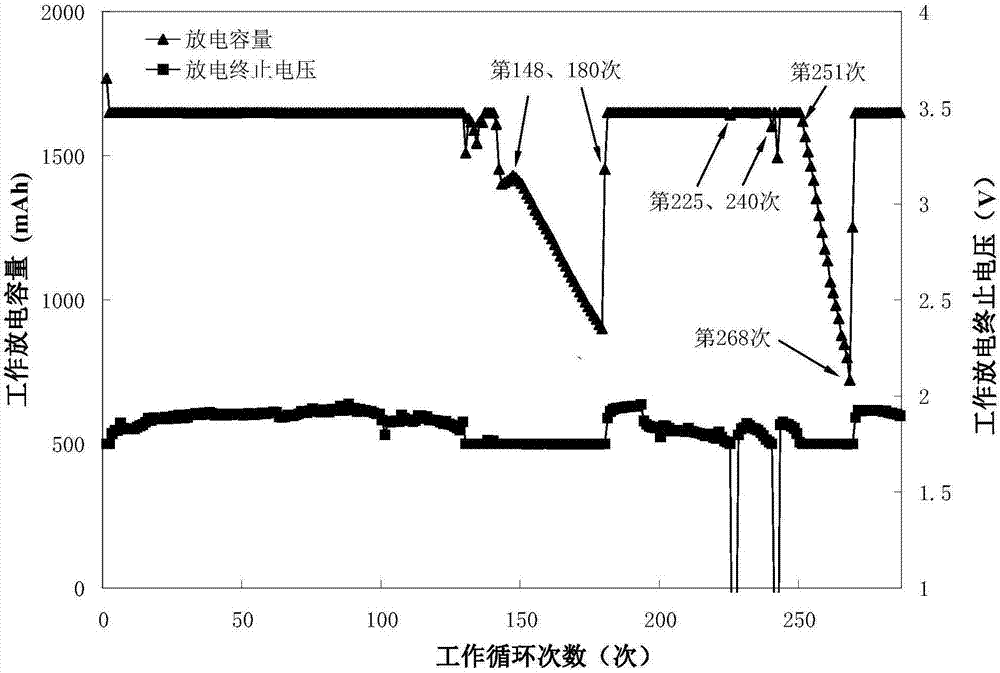

Embodiment 1

[0062] The lead-acid storage battery of this embodiment is a flat grid-type lead-acid storage battery with a rated capacity of 2.32Ah (2h rate, 25°C), and its working system is to charge with a constant current at a rate of 0.2 (rated capacity, the same below). After the voltage reaches 2.65V, charge at a constant voltage of 2.65V. The total time for two charges is 6 hours and 24 minutes, and then discharge at a rate of 2 hours and 80% DOD (depth of discharge), and then repeat the above charging and discharging process, that is Work through the above-mentioned charge-discharge cycle, and the working environment temperature is 25±1°C.

[0063] When the remaining capacity of the lead-acid storage battery of the present embodiment (the electric quantity that the battery can discharge last time, hereinafter the same) is 7.3% of its rated capacity, start to carry out the polarity reversal of the present invention and its subsequent charging or charging The discharge operation inclu...

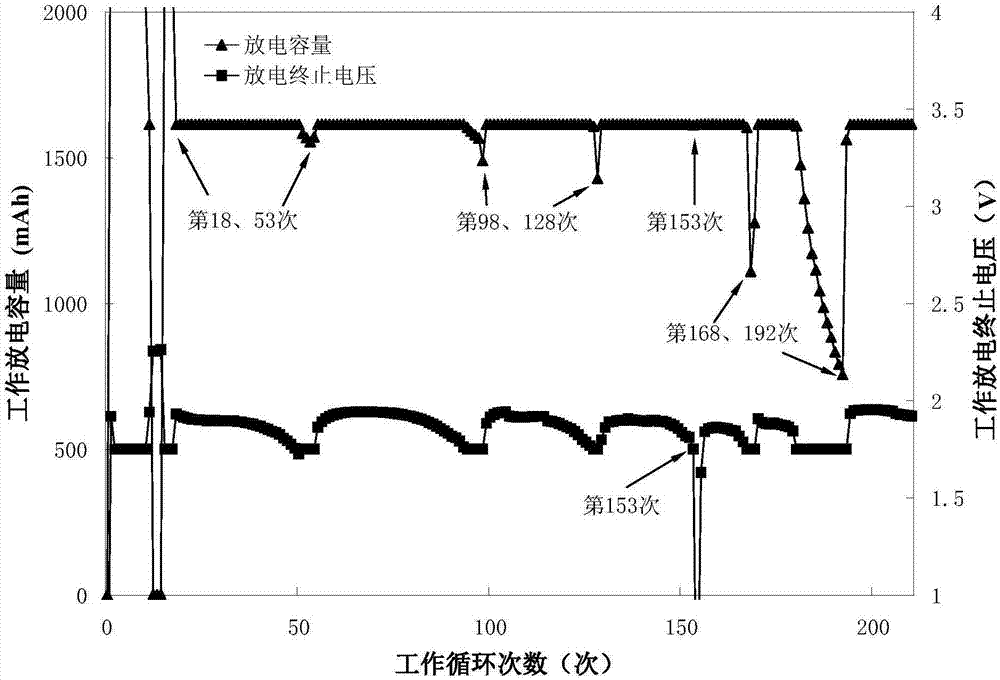

Embodiment 2

[0075] The lead-acid battery of this embodiment is a flat grid-type lead-acid battery with a rated capacity of 2.2Ah (2h rate, 25°C), and its working system is the same as that of Embodiment 1 of the present invention.

[0076]When the remaining capacity of the lead-acid storage battery of the present embodiment is 30% of its rated capacity, start to carry out the polarity reversal of the present invention and its subsequent charging or charging and discharging operations, including the following steps: 1) discharging and the first Secondary polarity reversal: stop the work of the battery, use a charging and discharging device to discharge the lead-acid battery of this embodiment with a current of 0.5 times (1098mA), so that the battery voltage drops from 2.65V when the battery stops working to 0V And finally drop to -0.26V, stop discharging, then stand still for 38min, and proceed to the next step; 2) Change the electrode connection after the first polarity reversal: manual op...

Embodiment 3

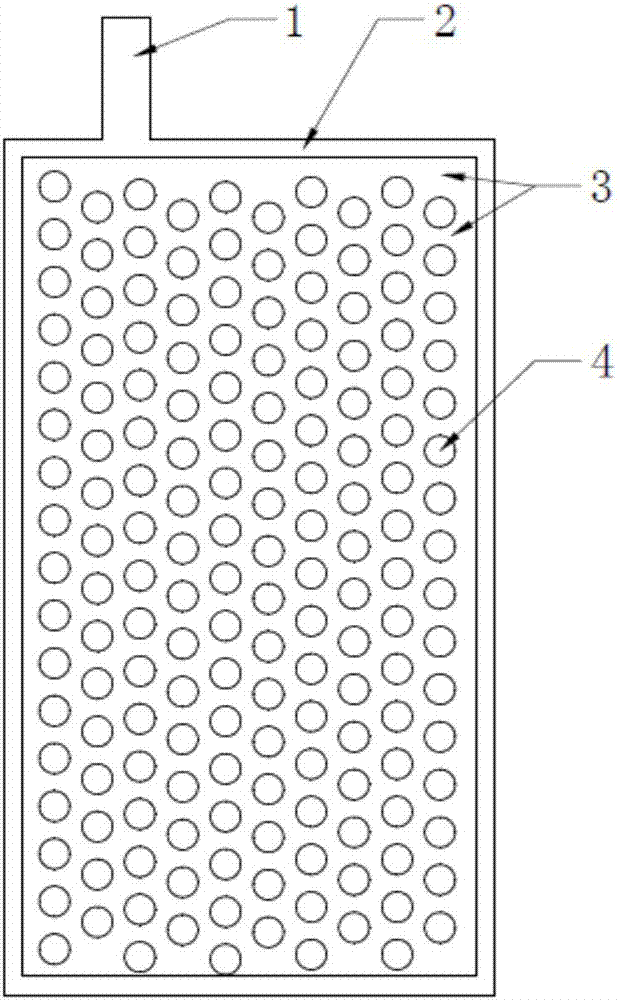

[0080] The implementation steps and operations of carrying out the polarity reversal of the present invention and the subsequent charging or charging and discharging operations of the lead-acid battery pack (rated capacity of 2h rate is 2Ah, rated voltage is 4V, 25°C) in this embodiment are the same as the present invention The steps and operations implemented on the battery in Invention Example 1 are basically the same, the difference is that in the operation of this example, the polarity reversal and the subsequent charging or discharging operation are applied to the positive electrode of the lead-acid battery pack and negative pole.

[0081] In other implementations of this embodiment, the charging stop voltage after each polarity reversal is 3.0V or 4.5V.

[0082] In other implementations of this embodiment, the polarity reversal and subsequent charging or charging and discharging operations of the present invention can also be performed on a single battery or some of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com