LED package method

A technology of LED packaging and LED chips, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of irradiating light, reducing the quantum efficiency of phosphor powder, and inconcentrating light, and achieve the effect of avoiding total reflection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

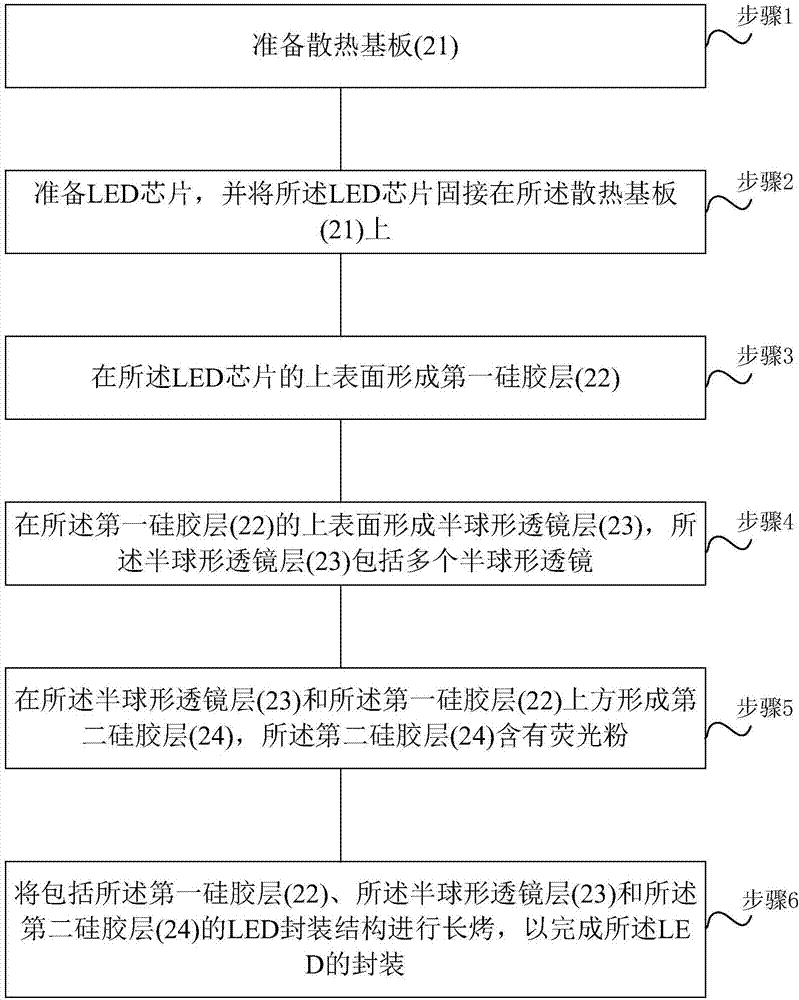

[0050] An embodiment of the present invention provides an LED packaging method, which includes,

[0051] Step 1, preparing the heat dissipation substrate 21;

[0052] Step 2, preparing LED chips, and fixing the LED chips on the heat dissipation substrate 21;

[0053] Step 3, forming a first silica gel layer 22 on the upper surface of the LED chip;

[0054] Step 4, forming a hemispherical lens layer 23 on the upper surface of the first silica gel layer 22, the hemispherical lens layer 23 comprising a plurality of hemispherical lenses;

[0055] Step 5, forming a second silica gel layer 24 above the hemispherical lens layer 23 and the first silica gel layer 22, the second silica gel layer 24 containing fluorescent powder;

[0056] Step 6, long-baking the LED package structure including the first silicone layer 22 , the hemispherical lens layer 23 and the second silicone layer 24 to complete the package of the LED.

[0057] Further, the LED chip is an aluminum gallium nitride u...

Embodiment 2

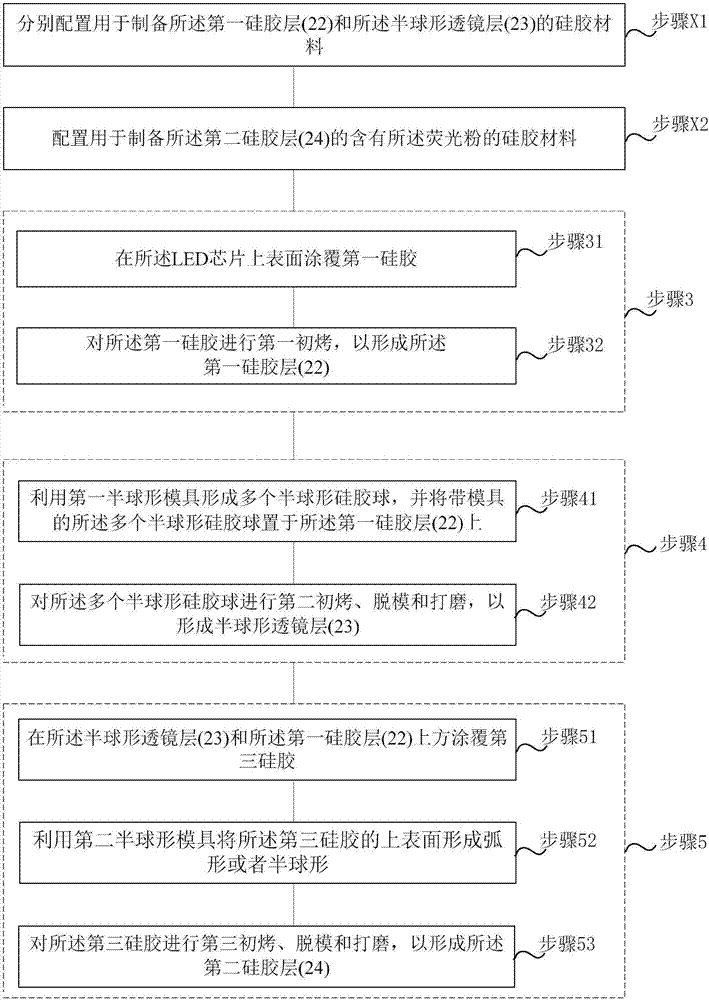

[0085] Please refer to figure 1 , figure 1 The flow chart of the LED packaging method provided by the embodiment of the present invention; wherein, on the basis of the above-mentioned embodiments, the LED packaging method provided by the embodiment of the present invention is introduced in detail, and the specific steps are as follows:

[0086] Step 1, preparing the heat dissipation substrate 21;

[0087] Step 11, selecting the heat dissipation substrate 21;

[0088] Specifically, a heat dissipation substrate 21 with a thickness D of 0.5-10mm and a solid iron plate is selected, and the heat dissipation substrate 21 is cut to a required size. The width W of the substrate is cut according to actual needs, which is not limited here.

[0089] Step 12, cleaning the heat dissipation substrate 21;

[0090] Specifically, clean the stains on the heat dissipation substrate 21, especially the oil stains;

[0091] Step 13, drying the heat dissipation substrate 21;

[0092] Specifical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com