LED packaging structure and high-concentration LED lamp

A technology of LED packaging and LED chips, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of decreasing quantum efficiency, reducing luminous efficiency, and dispersion of LED light source distribution, and achieve the effect of improving luminous dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

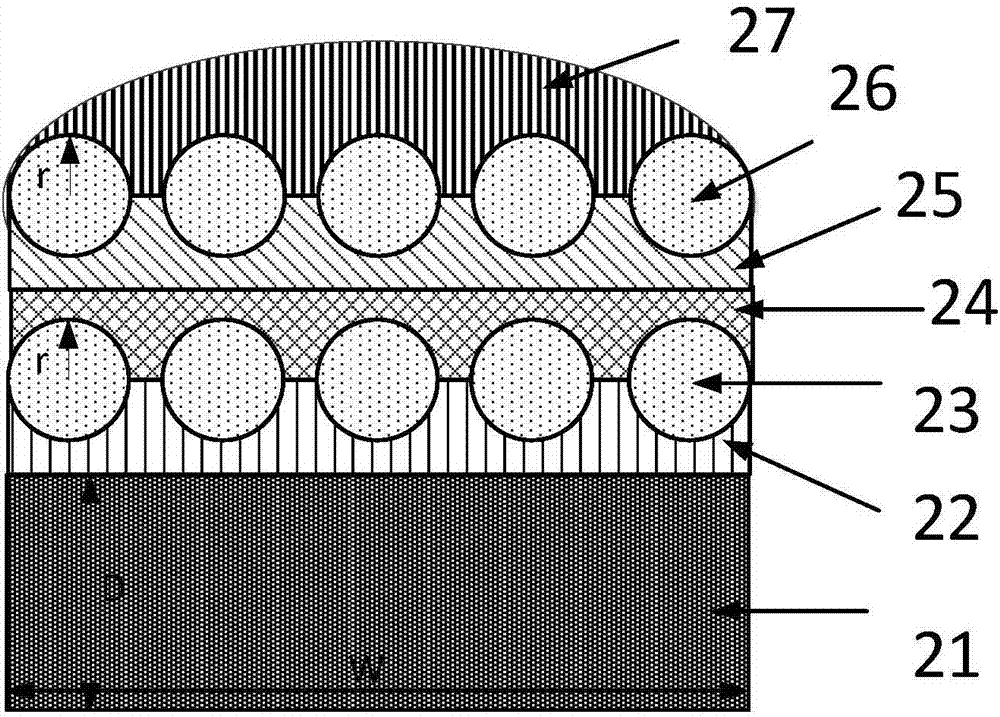

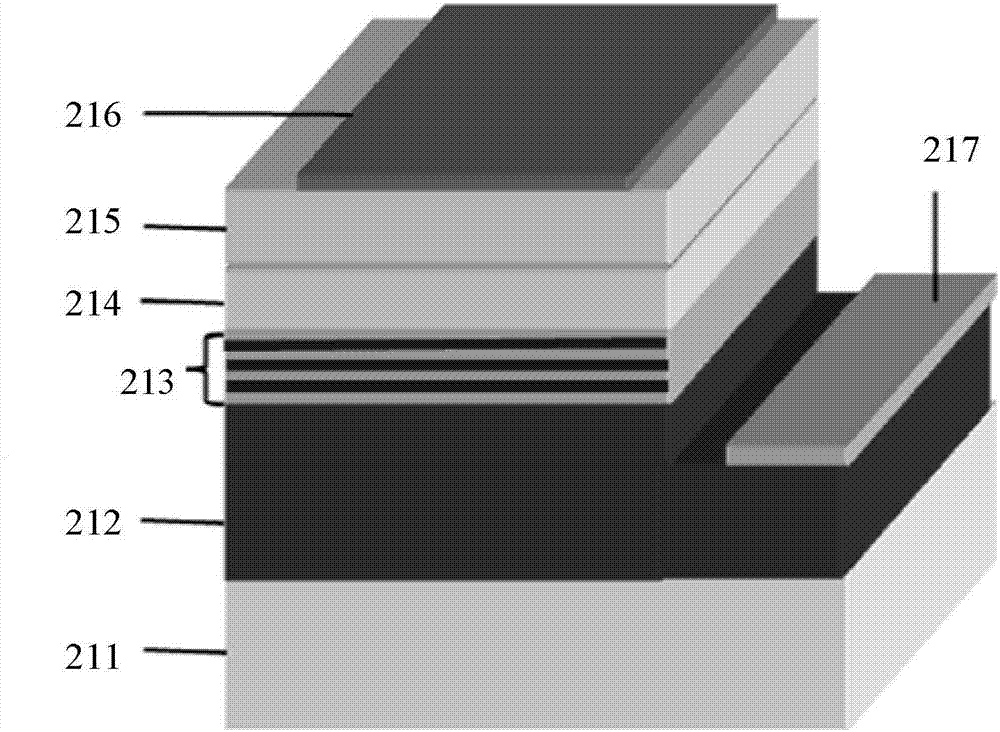

[0039] See figure 1 , figure 1 A schematic diagram of an LED packaging structure provided by an embodiment of the present invention, the packaging structure includes:

[0040] heat sink (21);

[0041] LED chips, arranged on the heat sink (21);

[0042] A first silica gel layer (22), coated on the LED chip and the heat sink (21);

[0043] A first lens layer (23), prepared on the first silica gel layer (22);

[0044] A second silica gel layer (24) and a third silica gel layer (25), which are successively arranged on the first lens layer (23);

[0045] A second lens layer (26), arranged on the third silica gel layer (25);

[0046] The fourth silica gel layer (27) is arranged on the second lens layer (26).

[0047] Further, on the basis of the above embodiment, the first silica gel layer (22) does not contain fluorescent powder, the first lens layer (23), the second silica gel layer (24), the third silica gel layer At least one of the layer (25), the second lens layer (26) ...

Embodiment 2

[0060] This embodiment further describes the LED package structure and its manufacturing method in the embodiment.

[0061] See Figure 4 , Figure 4 A schematic diagram of an LED packaging process flow provided by an embodiment of the present invention, the method includes:

[0062] Select the LED chip;

[0063] Welding the LED chip on the heat sink (21), placing the heat sink on the bracket;

[0064] A multi-layer silica gel layer is formed on the LED chip to realize the packaging of the LED chip, wherein the silica gel layer in contact with the LED chip in the multi-layer silica gel layer does not contain fluorescent powder.

[0065] In this embodiment, the silica gel layer in direct contact with the LED chip does not contain phosphor, and the phosphor is placed in other silica gel layers that do not directly contact the LED chip, avoiding direct contact between the phosphor powder and the LED chip. The reason for the implementation is: the chip has an absorption effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com