OPC (optical proximity correction) Method

A processing method and graphics technology, applied in special data processing applications, optics, instruments, etc., can solve the problems of shrinking graphics size, increasing the number of hot spots, and consuming a lot of OPC engineer time OPC calculation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment O

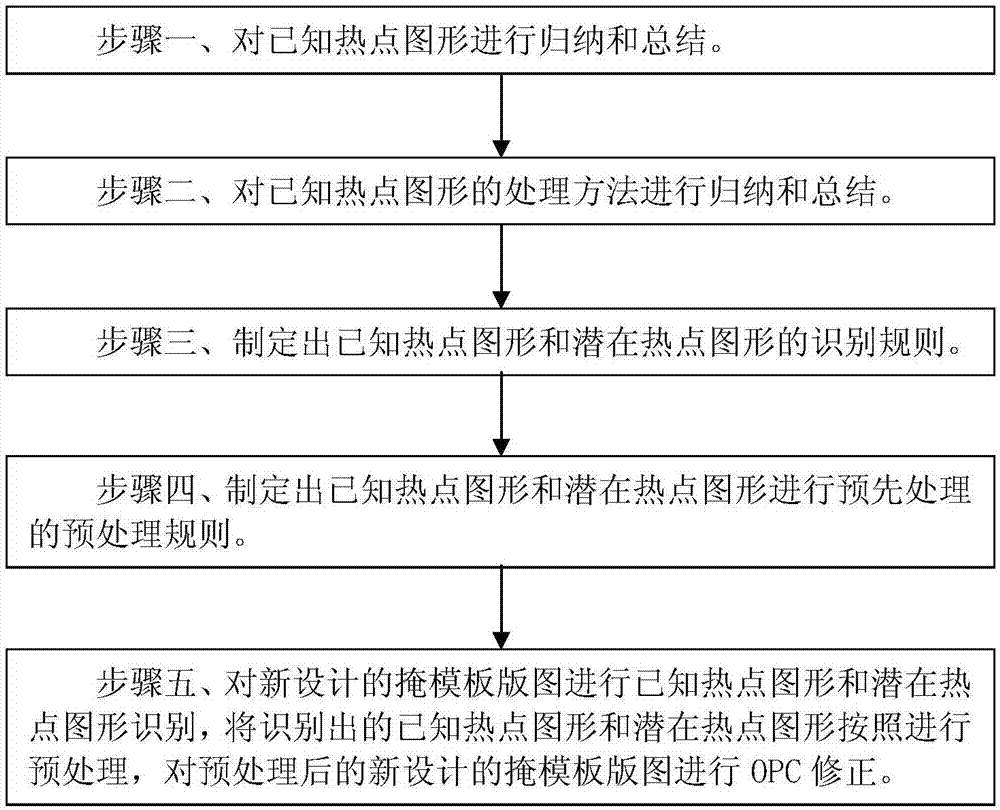

[0061] Such as figure 1 Shown is the flowchart of the OPC correction method of the embodiment of the present invention; the OPC correction method of the embodiment of the present invention comprises the following steps:

[0062] Step 1. Taking the hotspot patterns appearing in the OPC-corrected mask layout as known hotspot patterns and summarizing the known hotspot patterns.

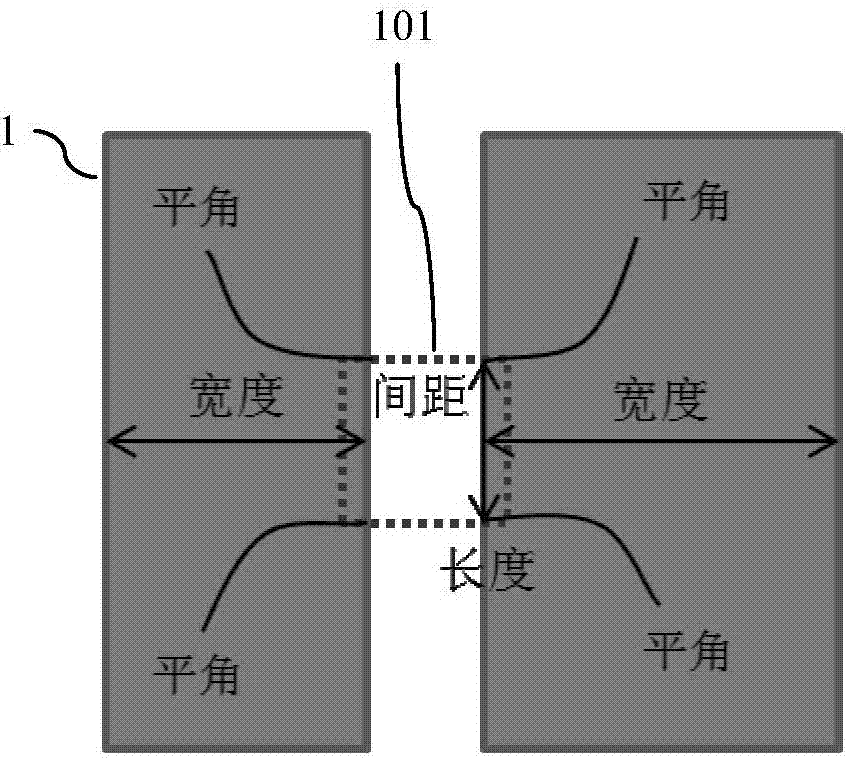

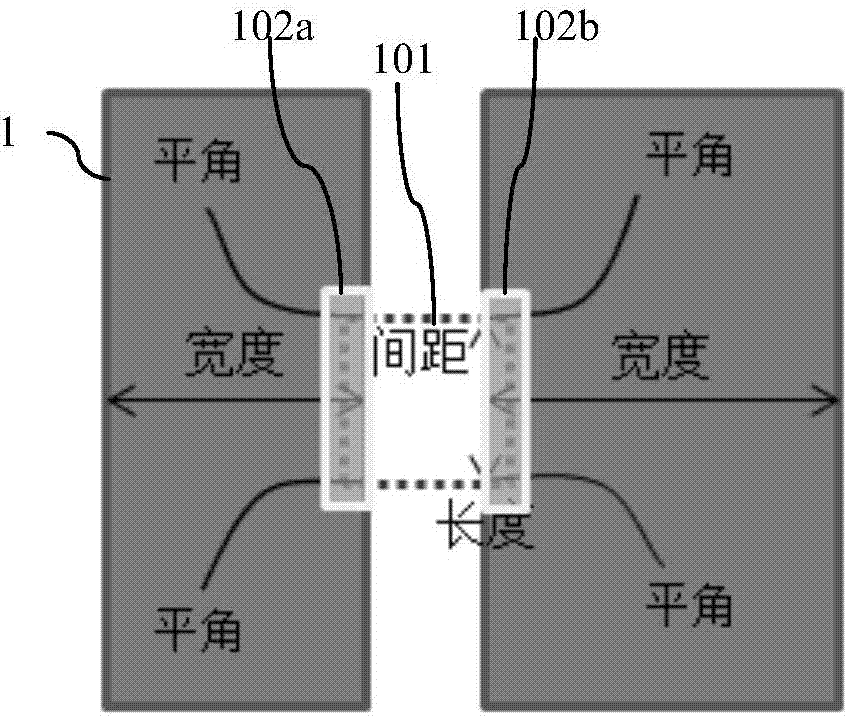

[0063] Such as Figure 2A Shown is the layout of the known hotspot graphics corresponding to the first short-circuit hotspot; Figure 3A Shown is the layout of the known hotspot graphics corresponding to the second short-circuit hotspot; Figure 4A As shown in , it is the layout of the known hotspot graphics corresponding to the connection error hotspots of the upper and lower layers; Figure 5A Shown is the layout of known hotspot graphics corresponding to open circuit hotspots; the steps of inducing and summarizing the known hotspot graphics include:

[0064] Classify and determine the parameters o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com