Grain dryer

A grain dryer and drying bin technology, applied in dryers, drying, local stirring dryers, etc., can solve the problems of affecting grain, grain mildew and deterioration, poor drying efficiency, etc., and reduce heat loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

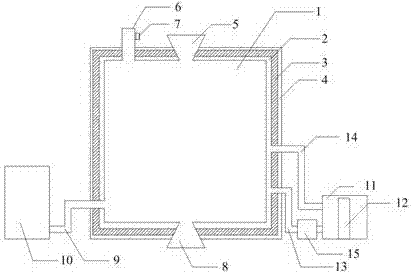

[0012] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0013] A grain dryer, characterized in that it comprises: a drying chamber 1 wrapping a cavity 2, the cavity 2 wrapping an insulation layer 3, the insulation layer 3 wrapping a casing 4, and the inlet 5 and the air outlet 6 are installed On the top of the drying bin 1, the air outlet 6 is installed on the left side of the inlet 5, and the middle of the bottom of the drying bin 1 is provided with a discharge port 8. The hot air blower 10 is connected to the side of the drying bin 1 through the hot air channel 9, and the water tank 11 The water pump 15 is installed on the delivery channel 13, the heater 12 is installed in the water tank 11, and the water in the water tank 11 is heated by the heater 12 and then used The water pump 15 is injected into the cavity 2 from the delivery channel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com