Heat pump system and control method of heat pump system

A heat pump system and control valve technology, applied in the field of heat exchange, can solve the problems of low defrosting heat, reliability problems, heat loss, etc., to increase evaporation heat absorption, improve defrosting effect, and reduce heat loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

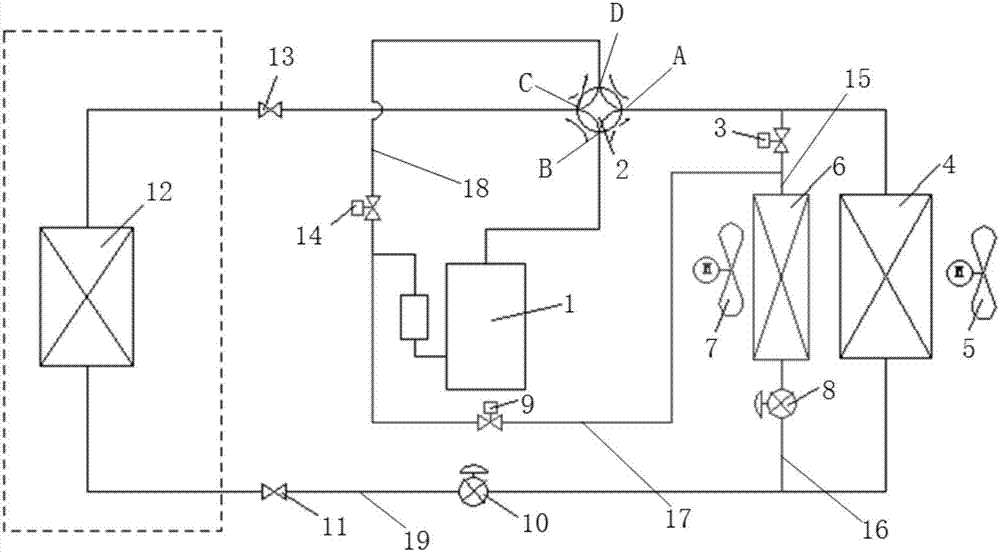

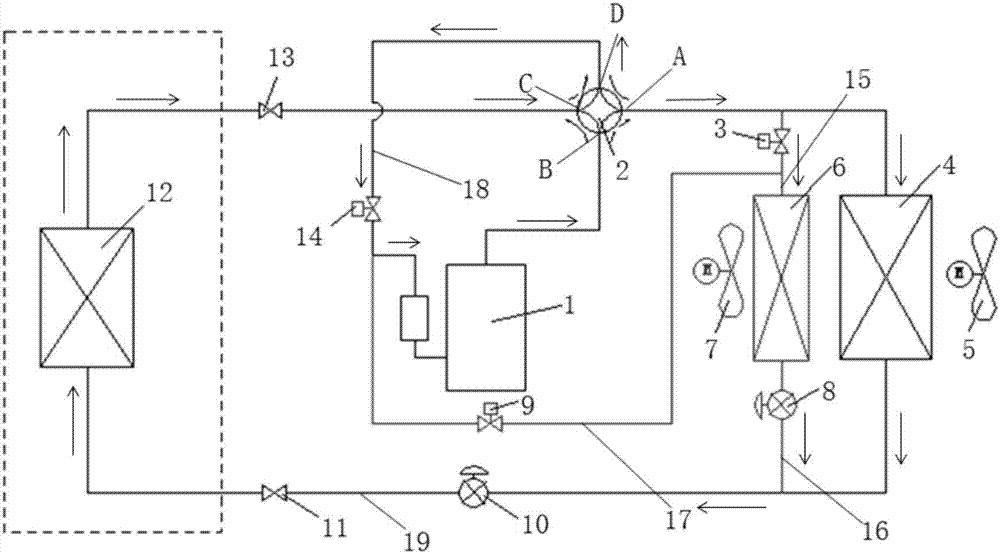

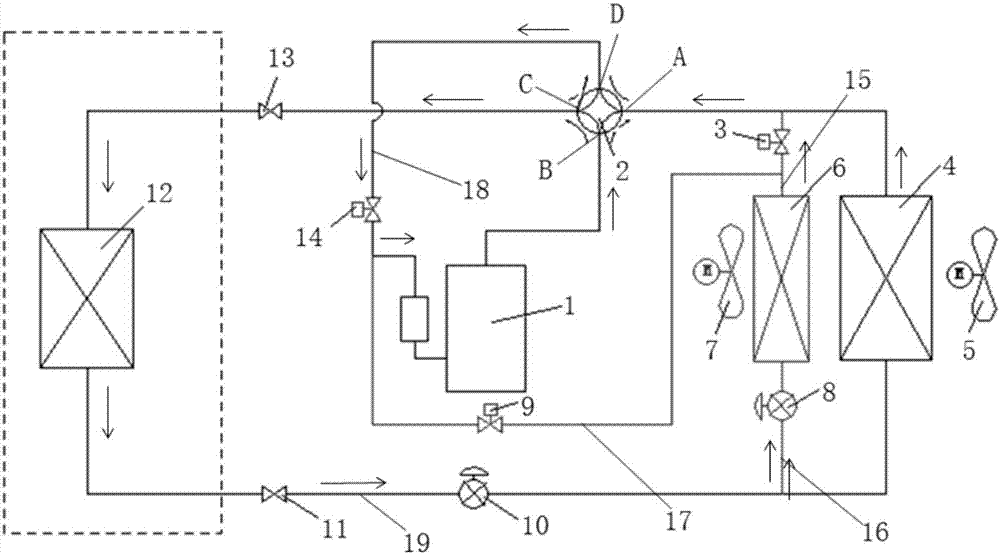

[0038] Combine figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, the heat pump system in the embodiment of the present application includes a compressor 1, an indoor heat exchanger 12, and an outdoor heat exchanger 4 connected in series on a circulating pipeline. The heat pump system further includes: an auxiliary heat exchanger 6; a first control pipeline 15. The first end and the second end of the first control pipe 15 are respectively connected to the first end of the outdoor heat exchanger 4 and the first end of the auxiliary heat exchanger 6; the second control pipe 16, the second control pipe The first end and the second end of the circuit 16 are respectively connected to the second end of the outdoor heat exchanger 4 and the second end of the auxiliary heat exchanger 6; the third control pipeline 17, the first end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com