Self-cleaning structure of range hood

A range hood and self-cleaning technology, which is applied in the field of self-cleaning, can solve the problems of unable to clean the volute, reduce the temperature of the volute, and uneven cleaning effect, and achieve good cleaning effect and increase the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

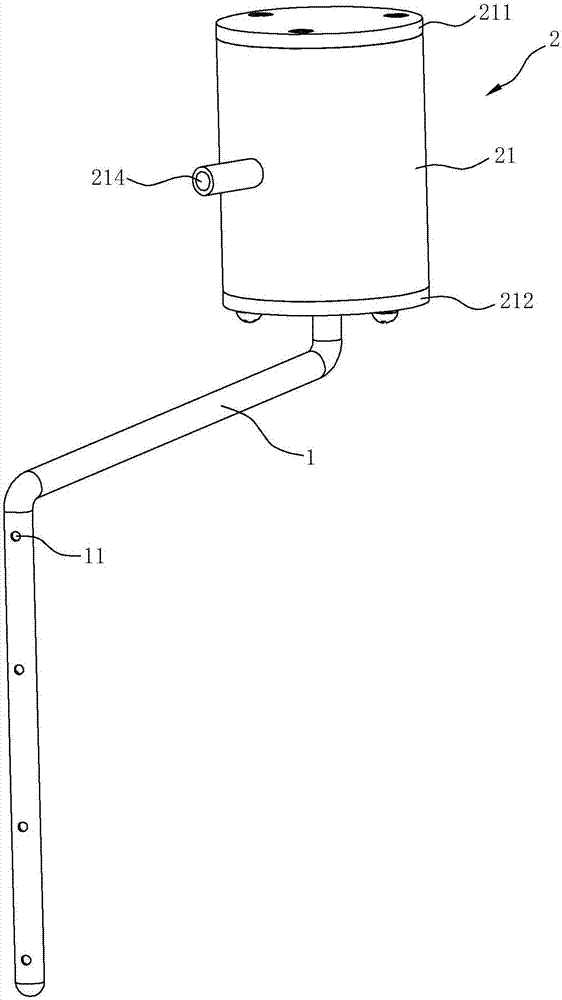

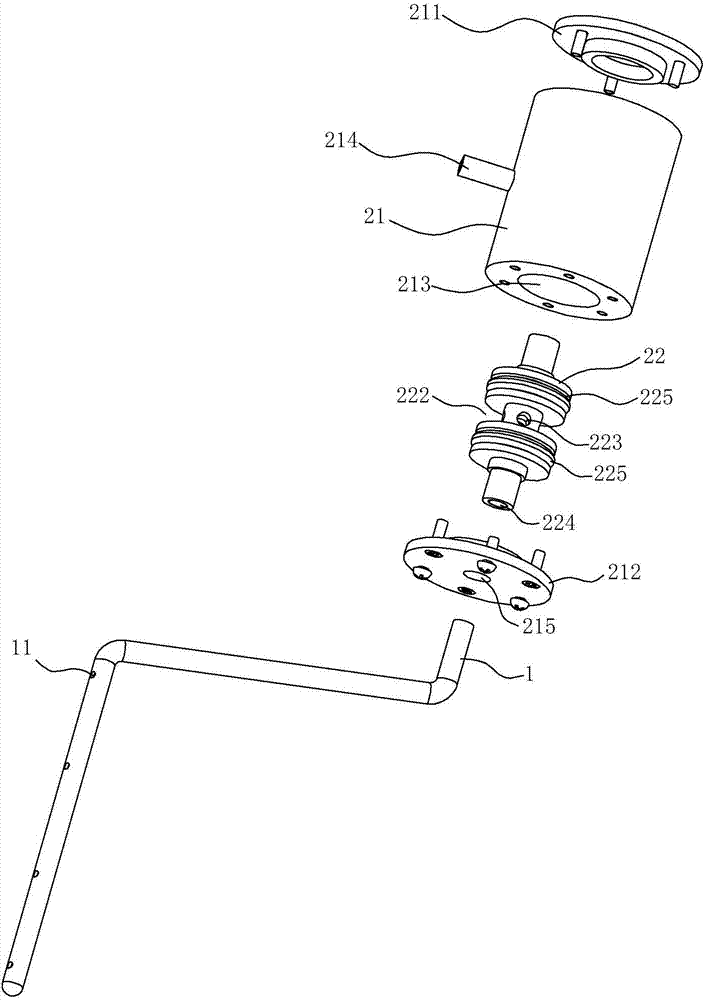

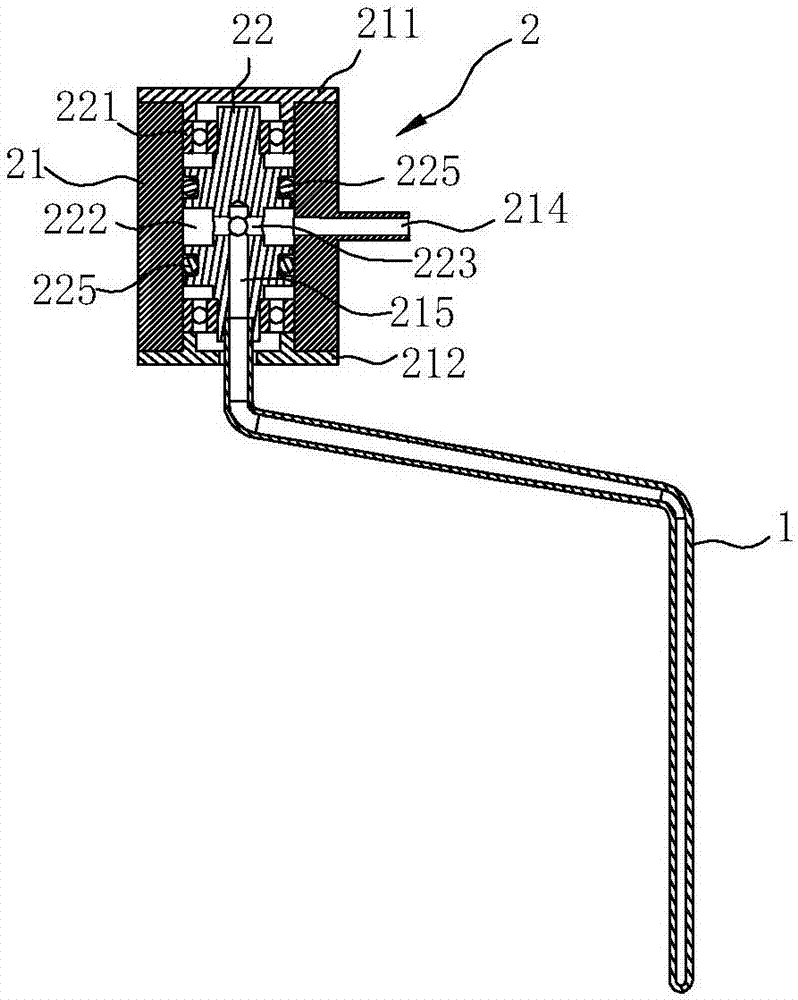

[0029] Such as Figure 1~4 As shown, the self-cleaning structure of the range hood in this embodiment includes a steam nozzle 1 and a driving structure 2 , both of which are arranged on the impeller 3 , and the impeller 3 is arranged in the volute 4 .

[0030] In this embodiment, the volute 4 is provided with an air inlet 41 of the impeller 3, and a mesh ring 42 is installed on the air inlet 41, and the driving structure 2 is fixed on the outside of the mesh ring 42 by screws, and one end of the steam nozzle 1 is connected to the driving The structure 2 is connected, the other end of the steam nozzle 1 extends into the impeller 3 through the mesh ring 42, and the middle part of the steam nozzle 1 extends toward the blade of the impeller 3, and the lower part of the steam nozzle 1 extends along the length direction of the blade of the impeller 3 Arranged, when the steam nozzle 1 rotates, it can form a circular movement track in the inner peripheral space of the impeller 3 .

...

Embodiment 2

[0036] The difference between this embodiment and embodiment 1 is only: as Figure 5As shown, the driving structure 2 of this embodiment also includes a motor 23 , the motor 23 is arranged on the top of the sleeve 21 and the output shaft 231 extends into the sleeve 21 and is connected with the upper end of the connecting member 22 . Specifically, the first end cap 211 on the top of the sleeve 21 is provided with an opening 216 through which the output shaft 231 of the power supply motor 23 passes, and the upper end of the connector 22 extends upwards to form a connecting portion 226, which is connected to the motor 23. The output shaft 231 is connected through a coupling 232 .

[0037] After the motor 23 is added in this embodiment, the motor 23 can be used to drive the connector 22 to drive the steam nozzle 1 to rotate, which is beneficial to control the speed of the steam nozzle 1 and achieve a better steam cleaning effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com