Water stop clamping tool, tunnel longitudinal water stop structure and construction method

A longitudinal water-stop and water-stop technology, used in tunnels, tunnel linings, and earth-moving drilling, etc., can solve the problems of water-stop parts distortion, difficult positioning, serious distortion, etc., to ensure the water-stop effect, achieve accurate positioning, The effect of ensuring project safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

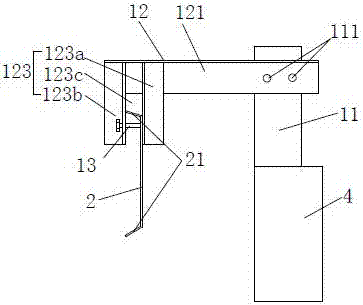

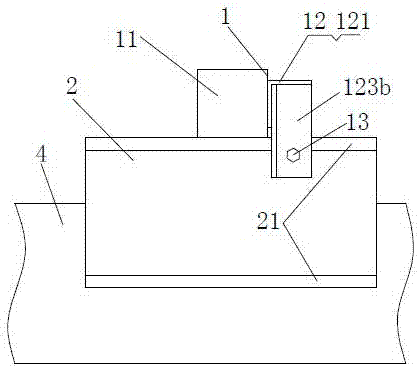

[0062] Such as figure 1 , figure 2 , image 3 with Image 6 As shown, the waterstop clamp 1 includes a fixing part 11 for being installed on the tunnel side wall template 4, and a connecting part 12 connected with the fixing part 11 and extending to the top of the concrete pouring area 6, the The connection part 12 is provided with a mounting structure 13 for connecting the water stop belt 2, and the relative position between the water stop belt 2 and the connection part 12 can be adjusted, so that after the water stop belt 2 is connected to the connection part 12, the The water stop 2 corresponds to the construction joint 3, and the water stop 2 is a metal plate water stop.

[0063] Further, the formwork for the side wall of the tunnel is an inverted trestle side formwork. During the construction process of the inverted arch trestle, the waterstop clamp is installed on the side formwork of the inverted arch trestle, which has the advantages of convenient installation and ...

Embodiment 2

[0072] Such as Figure 4 with Figure 5 As shown, the waterstop clamp of this embodiment is the same as that of Embodiment 1, only the structure of the connecting portion 12 is different.

[0073] The connecting part 12 includes a crossbeam 121 connected with the fixing part 11, the crossbeam 121 is arranged substantially horizontally, the end of the crossbeam 121 is connected with a longitudinal beam 122, and the longitudinal beam 122 is substantially vertically arranged, and the installation structure 13 is set on The vertical strip holes on the longitudinal beams 122 are provided with fasteners 13A for installing the waterstop 2 on the longitudinal beams 122. strip holes, so that after the waterstop 2 is installed on the longitudinal beam 122, it can move up and down along the vertical strip holes, so as to realize the position adjustment of the waterstop 2 in the vertical direction and complete the positioning of the waterstop.

[0074] Further, the beams 121 and the lon...

Embodiment 3

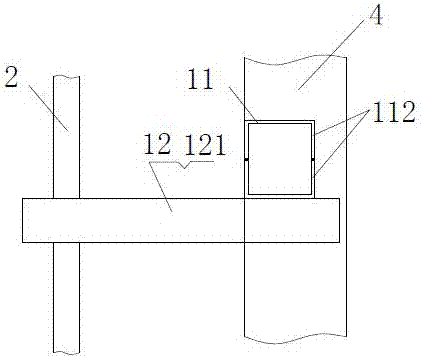

[0076] Such as Image 6 with Figure 7 As shown, the tunnel longitudinal waterstop structure includes a metal plate-shaped waterstop 2 arranged along the longitudinal direction of the tunnel, and a plurality of waterstops as in Example 1 are arranged along the length direction of the metal plate-shaped waterstop 2 Fixture 1, the waterstop fixture 1 is installed on the tunnel side wall template 4, the centerline of the metal plate waterstop 2 roughly coincides with the centerline of the construction joint 3, and the metal plate waterstop 2 is installed The radial position allows a deviation of ±50mm, and the longitudinal direction allows deviation from the center to be ±30mm.

[0077] The longitudinal water-stop structure of the tunnel adopted in this scheme makes the construction joints have a good waterproof effect without water seepage. The radial position of the metal plate water-stop installation refers to the horizontal position of the water-stop, while the metal plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com