Three-channel continuous flexible composite pipe connection connector and mounting method

A technology of flexible composite pipes and connecting joints, which is used in drilling pipes, casings, and earth-moving drilling and mining, etc., can solve the problems that three-channel continuous flexible composite pipes cannot be connected, and achieve the effect of ensuring sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This example provides figure 1 The shown connection joint of a three-channel continuous flexible composite pipe includes a connector 2, and the ends of two sections of three-channel continuous flexible composite pipe 1 are respectively inserted into the connector 2 and connected through the connector 2.

[0032] The ends of the two sections of three-channel continuous flexible composite pipe 1 are respectively inserted into the connector 2, and sealed by a sealing ring in the connector 2. This connector solves the problem of connecting two three-channel continuous flexible composite pipes and ensures the three channels Independent.

[0033] Such as figure 2 As shown, the three-channel continuous flexible composite pipe connection joint also includes a movable joint 8 and a fastening pressure ring 10, and the fastening pressure ring 10 is worn on the three-channel continuous flexible composite pipe 1 and is in tight contact with the end surface of the connection head 2...

Embodiment 2

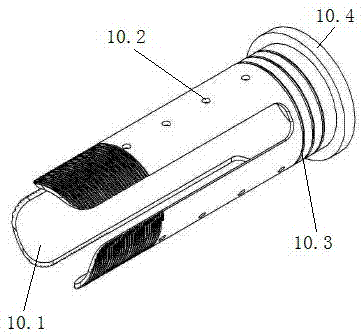

[0036] On the basis of Example 1, such as image 3 with Figure 4 As shown, the fastening pressure ring 10 is composed of a ring-shaped base 10.4 and a plurality of strip-shaped arc-shaped plates 10.1, and a plurality of strip-shaped arc-shaped plates 10.1 surround a circle, and one end thereof is connected to the ring-shaped base 10.4 and connected A plurality of sealing ring grooves 10.3 are provided along the circumferential direction in part, and threads are provided at the other end, and a row of screw holes 10.2 are provided in each strip arc-shaped plate 10.1 along the length direction.

[0037] The fastening pressure ring 10 is worn on the three-channel continuous flexible composite pipe, and is closely attached to the three-channel composite pipe through the screw 6 to increase the axial expansion and contraction.

Embodiment 3

[0039] On the basis of Example 2, such as image 3 with Figure 4 As shown, the ring-shaped base 10.4 and the strip-shaped arc-shaped plate 10.1 are integrally formed to form a fastening pressure ring 10, and the three-channel continuous flexible composite pipe 1 passes through the fastening pressure ring 10 and extends into the connector 2, and the movable connector 8 Wear it on the outer surface of the fastening pressure ring 10 and the connector 2. It also includes a protective tube 3, which is sheathed on the outer surface of the strip-shaped arc-shaped plate 10.1 of the fastening pressure ring 10, and fastened with the threads on the strip-shaped arc-shaped plate 10.1. A copper pressure ring 5 sleeved on the three-channel continuous flexible composite pipe 1 is provided between the protection cylinder 3 and the fastening pressure ring 10 . A seal ring II9 is provided between the movable joint 8 and the fastening pressure ring 10, a seal ring I4 is provided between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com