Nano fiber/short fiber blended yarn preparing device and method with nano fiber anti-adhesion mechanism

A nanofiber and anti-adhesion technology, applied in the direction of continuous winding spinning machine, spinning machine, open-end spinning machine, etc., can solve the problem of nanofiber winding down the output roller and affecting the functional nanofiber content of textiles and other problems, to achieve the effect of simple device, good guiding value and improved content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

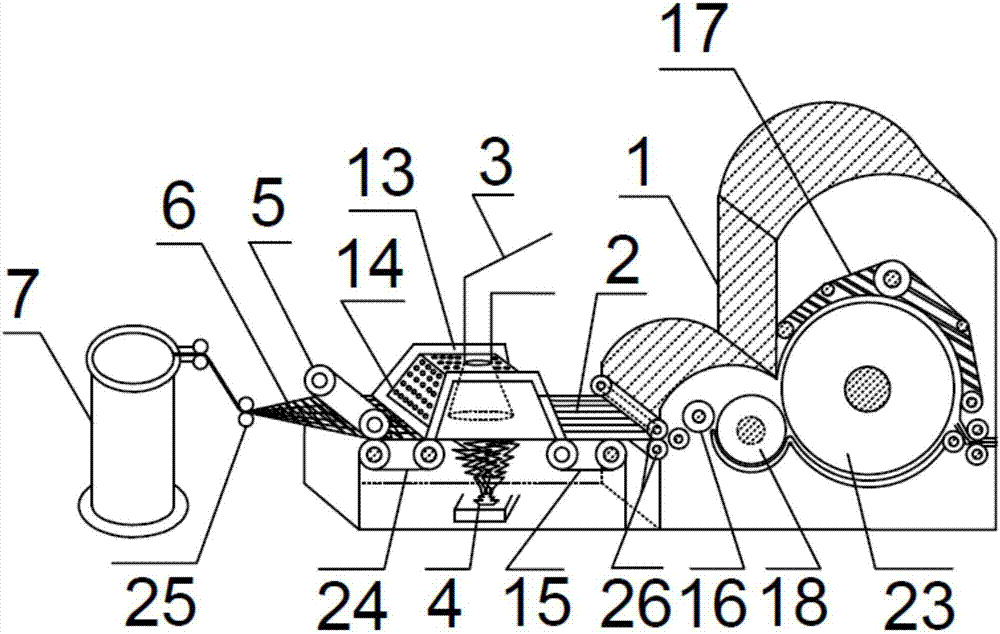

[0035] This embodiment provides a device with a nanofiber anti-adhesion mechanism for preparing nanofiber / short fiber blended yarn. A conveyor belt 15 is provided on one side of the carding machine 1, and a fiber web transmission is provided on the other side of the conveyor belt 15. Device 13, the fiber web transmission device 13 comprises a transmission support net curtain 14 and a negative pressure suction device 3, the negative pressure suction device 3 is arranged in the transmission support net curtain 14, the transmission support net curtain 14 is connected with the transmission belt 15, and the transmission support The other side of the net curtain 14 is connected with the conveying belt 24, the web conveying device 13 is above the conveying belt 15 and the conveying belt 24, and the electrospinning device 4 is arranged below the web conveying device 13, and the web conveying device 13 passes through Belt 24 links to each other with output device 5, and the other side o...

Embodiment 2

[0040] This embodiment provides a device with a nanofiber anti-adhesion mechanism for preparing nanofiber / short fiber blended yarn. A conveyor belt 15 is provided on one side of the carding machine 1, and a fiber web transmission is provided on the other side of the conveyor belt 15. Device 13, the fiber web transmission device 13 comprises a transmission support net curtain 14 and a negative pressure suction device 3, the negative pressure suction device 3 is arranged in the transmission support net curtain 14, the transmission support net curtain 14 is connected with the transmission belt 15, and the transmission support The other side of the net curtain 14 is connected with the conveying belt 24, the web conveying device 13 is above the conveying belt 15 and the conveying belt 24, and the electrospinning device 4 is arranged below the web conveying device 13, and the web conveying device 13 passes through Belt 24 links to each other with output device 5, and the other side o...

Embodiment 3

[0045] This embodiment provides a device with a nanofiber anti-adhesion mechanism for preparing nanofiber / short fiber blended yarn. A conveyor belt 15 is provided on one side of the carding machine 1, and a fiber web transmission is provided on the other side of the conveyor belt 15. Device 13, the fiber web transmission device 13 comprises a transmission support net curtain 14 and a negative pressure suction device 3, the negative pressure suction device 3 is arranged in the transmission support net curtain 14, the transmission support net curtain 14 is connected with the transmission belt 15, and the transmission support The other side of the net curtain 14 is connected with the conveying belt 24, the web conveying device 13 is above the conveying belt 15 and the conveying belt 24, and the electrospinning device 4 is arranged below the web conveying device 13, and the web conveying device 13 passes through Belt 24 links to each other with output device 5, and the other side o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com