High-heat-conductivity MgO doped molten nitrate heat-transfer and heat-storing material as well as in-situ generation method and application thereof

A technology of in-situ generation method and heat storage material, which is applied to high thermal conductivity MgO doped nitric acid molten salt heat transfer and heat storage material and its in-situ generation method and application fields, can solve the problem of phase separation between molten salt liquid and solid particles, nitric acid Problems such as low thermal conductivity of molten salt, to achieve the effect of improving thermal conductivity, increasing specific heat, and reducing pumping power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

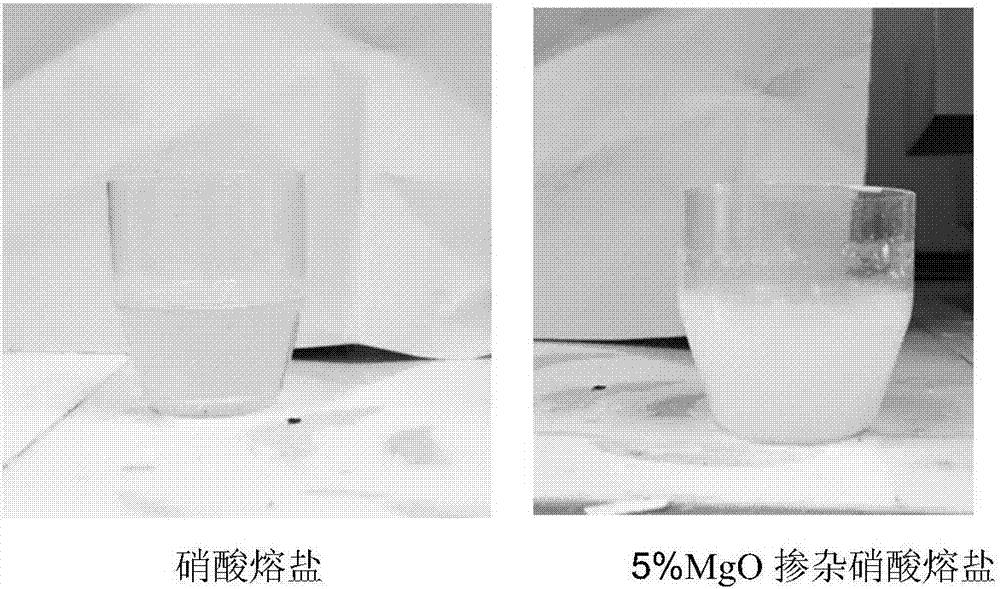

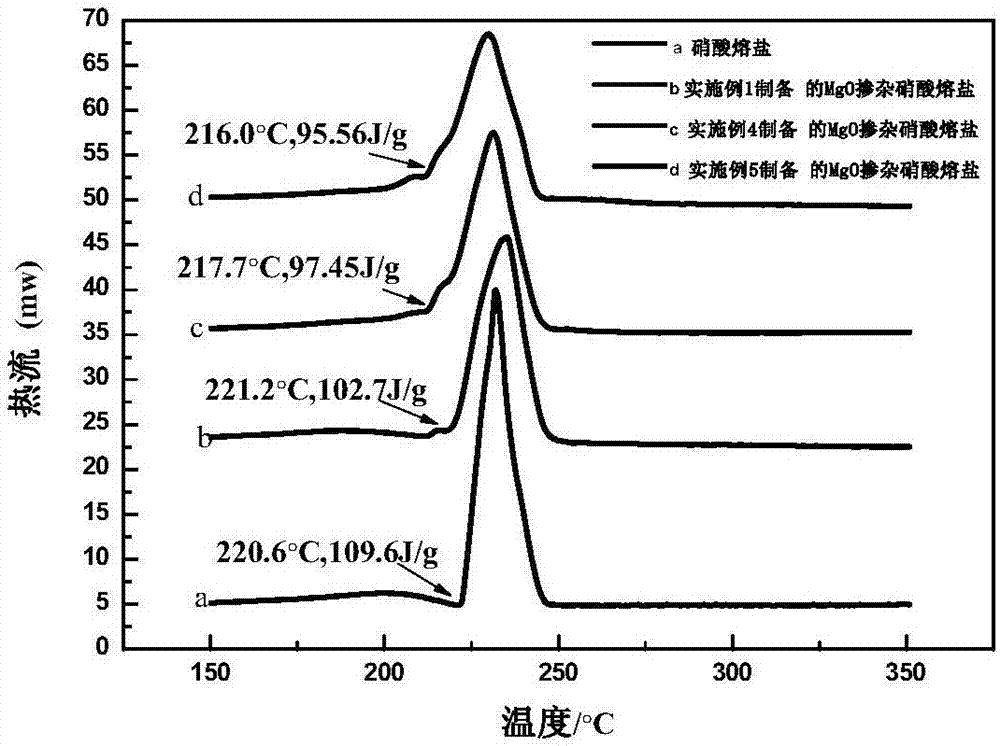

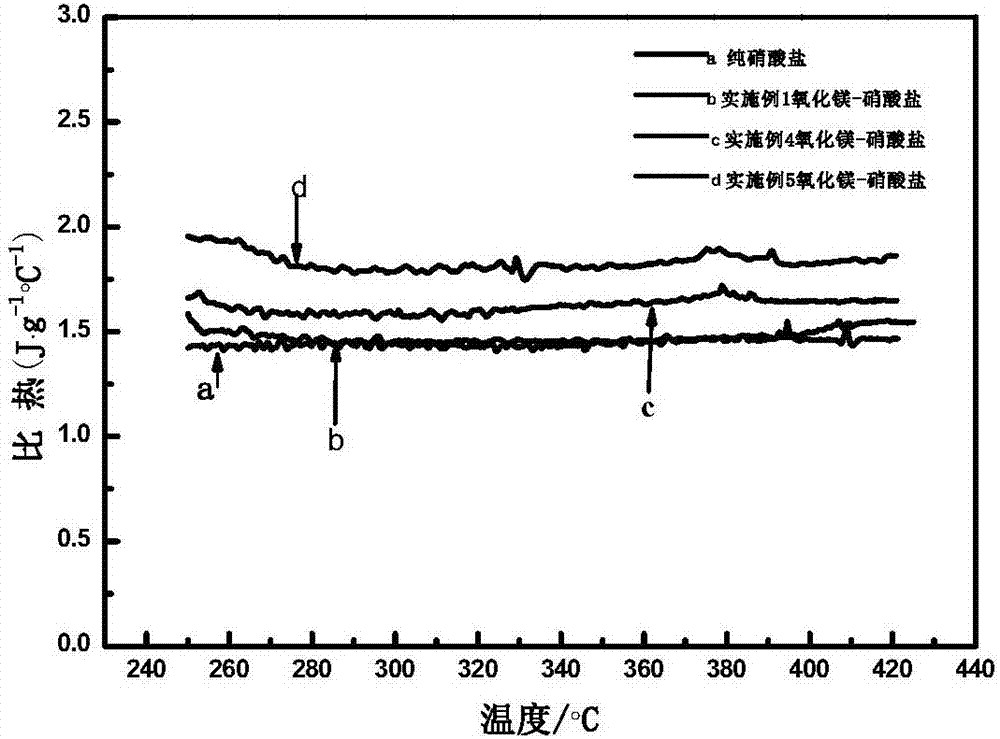

[0031] A method for preparing a high thermal conductivity MgO-doped nitric acid molten salt heat transfer and heat storage material by an in-situ generation method, the specific implementation steps are as follows:

[0032] Dried potassium nitrate and sodium nitrate are mixed by the lowest eutectic point ratio of its binary phase diagram to obtain the raw material mixture I of nitric acid molten salt; (NO 3 ) 2 ·6H 2 O was added to mixture I to obtain Mg(NO 3 ) 2 ·6H 2 O-doped nitric acid molten salt raw material mixture II. After mixing the mixture II evenly, the temperature was raised to 420°C at a heating rate of 10°C / min until the molten salt melted, and reacted at a constant temperature for 10 hours to form a uniformly suspended MgO-doped nitric acid molten salt fluid without phase separation, and cooled naturally to room temperature. Mechanical pulverization to obtain a high thermal conductivity MgO doped nitric acid molten salt heat transfer heat storage material. ...

Embodiment 2

[0037] A method for preparing a high thermal conductivity MgO-doped nitric acid molten salt heat transfer and heat storage material by an in-situ generation method, the specific implementation steps are as follows:

[0038] Dried potassium nitrate and sodium nitrate are mixed by the lowest eutectic point ratio of its binary phase diagram to obtain the raw material mixture I of nitric acid molten salt; then according to the mass ratio equivalent to MgO: nitric acid molten salt is 3.5:96.5 ratio, MgCl 2 ·6H 2 O was added to mixture I to give MgCl 2 ·6H 2 O-doped nitric acid molten salt raw material mixture II. After the mixture II is mixed evenly, the temperature is programmed to 450°C at a heating rate of 10°C / min until the molten salt is melted, and the constant temperature is reacted for 15 hours to form a uniformly suspended MgO-doped nitric acid molten salt fluid without phase separation, which is naturally cooled to room temperature. Mechanical pulverization to obtain a...

Embodiment 3

[0041] A method for preparing a high thermal conductivity MgO-doped nitric acid molten salt heat transfer and heat storage material by an in-situ generation method, the specific implementation steps are as follows:

[0042] Dried potassium nitrate and sodium nitrate are mixed by the lowest eutectic point ratio of its binary phase diagram to obtain the raw material mixture I of nitric acid molten salt; (NO 3 ) 2 ·6H 2 O was added to mixture I to obtain Mg(NO 3 ) 2 ·6H 2 O-doped nitric acid molten salt raw material mixture II. After the mixture II was mixed evenly, the temperature was raised to 500°C at a heating rate of 10°C / min until the molten salt melted, and reacted at a constant temperature for 24 hours to form a uniformly suspended MgO-doped nitric acid molten salt fluid without phase separation, and cooled naturally to room temperature. Mechanical pulverization to obtain a high thermal conductivity MgO doped nitric acid molten salt heat transfer heat storage materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com