Method for preparing reclaimed rubber powder from waste tire rubber powder

A technology for waste tire rubber and reclaimed rubber powder, applied in the direction of plastic recycling and recycling technology, can solve the problems of poor processing performance and mechanical properties of reclaimed rubber powder, and achieve excellent processing performance, improved system pore structure, and processing performance. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

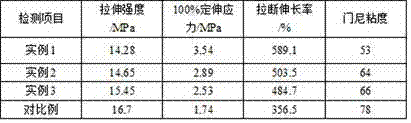

Examples

example 1

[0022] After mixing the waste tire rubber powder with 10% hydrochloric acid in a mass ratio of 1:40, ultrasonic impregnation at an ultrasonic frequency of 50 kHz for 60 minutes, and filtration to obtain an acid leaching material, and the obtained acid leaching material and the mass fraction After mixing 12% sodium hydroxide solution at a mass ratio of 1:40, ultrasonically impregnate for 60 minutes at an ultrasonic frequency of 50 kHz, filter to obtain an alkali leaching material, and wash the obtained alkali leaching material with deionized water until the washing liquid becomes neutral. Then transfer the washed alkali leaching material into an oven, and dry it to a constant weight at a temperature of 110°C to obtain pretreated waste tire rubber powder; pour the inorganic salt into a crucible, and stir it with a glass rod. Heat until the inorganic salt is completely melted to obtain molten salt, then pour the molten salt into the electrolytic cell while it is hot, and add pretr...

example 2

[0024]Mix waste tire rubber powder with 9% hydrochloric acid at a mass ratio of 1:30, then ultrasonically impregnate for 50 minutes at an ultrasonic frequency of 47kHz, filter to obtain an acid leaching material, and combine the obtained acid leaching material with the mass fraction After mixing 11% sodium hydroxide solution at a mass ratio of 1:30, ultrasonically impregnate for 47 minutes at an ultrasonic frequency of 47kHz, filter to obtain an alkali leaching material, and wash the obtained alkali leaching material with deionized water until the washing liquid becomes neutral. Then transfer the washed alkali leaching material into an oven, and dry it to constant weight at a temperature of 107°C to obtain pretreated waste tire rubber powder; pour the inorganic salt into a crucible, and stir it with a glass rod. Heat until the inorganic salt is completely melted to obtain molten salt, then pour the molten salt into the electrolytic cell while it is hot, and add pretreated waste...

example 3

[0026] Mix waste tire rubber powder with 8% hydrochloric acid at a mass ratio of 1:20, then ultrasonically impregnate for 45 minutes at an ultrasonic frequency of 45 kHz, and filter to obtain an acid leaching material, and combine the obtained acid leaching material with the mass fraction After mixing 10% sodium hydroxide solution at a mass ratio of 1:20, ultrasonically impregnate for 45 minutes at an ultrasonic frequency of 45kHz, filter to obtain alkali leaching materials, and wash the obtained alkali leaching materials with deionized water until the washing liquid becomes neutral. Then transfer the washed alkali leaching material into an oven, and dry it to a constant weight at a temperature of 105°C to obtain pretreated waste tire rubber powder; pour the inorganic salt into a crucible, and stir it with a glass rod. Heat until the inorganic salt is completely melted to obtain molten salt, then pour the molten salt into the electrolytic cell while it is still hot, and add pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com