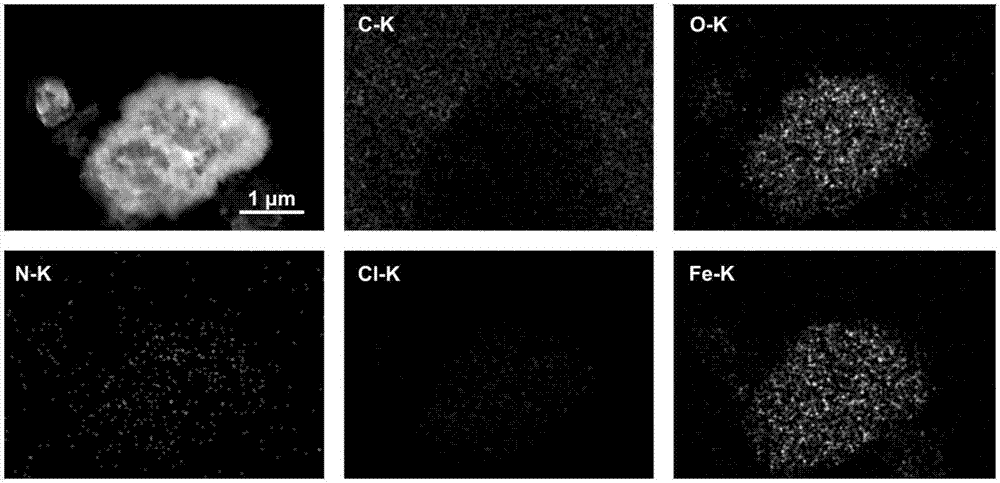

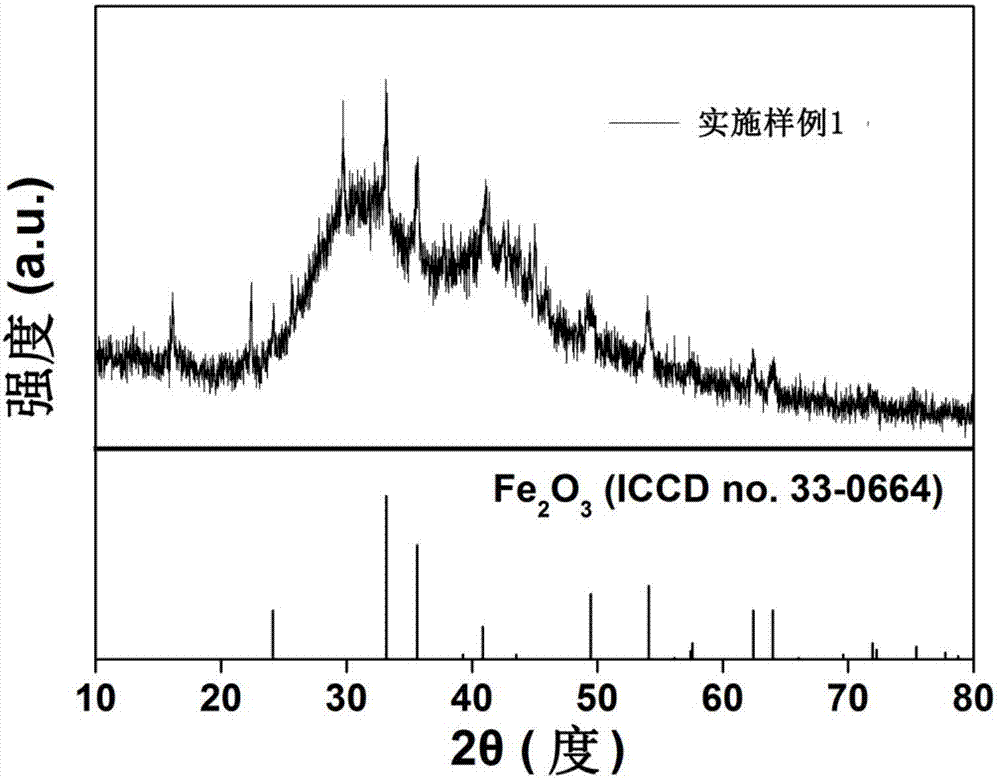

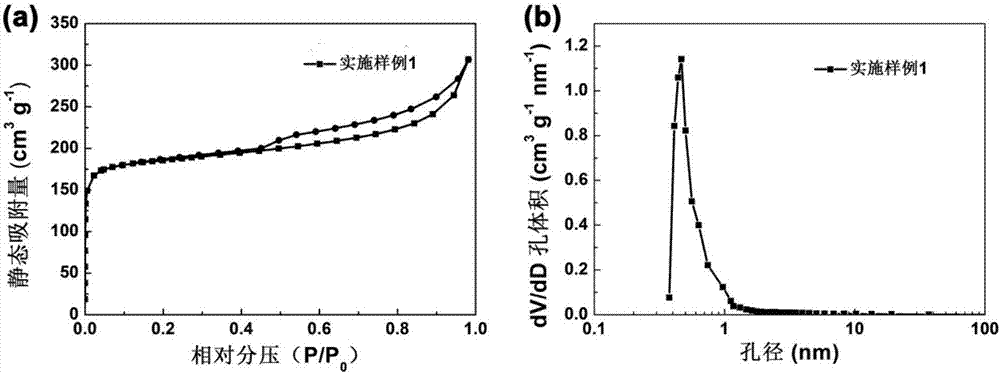

Preparation method of N-doped porous carbon loaded Fe2O3 composite material

A nitrogen-doped porous carbon, composite material technology, applied in nanotechnology for materials and surface science, carbon compounds, chemical instruments and methods, etc., can solve the problem of high manufacturing cost of carrier materials, unstable nanomaterials, skeleton materials The problems such as the collapse and deformation of the channel, to achieve the effect of uniform size, excellent channel structure, and improved dispersion and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Preparation of poly-4-vinylpyridine / absolute ethanol solution: at room temperature, take 0.21 g of poly-4-vinylpyridine (molecular weight 60,000) and add it to 50 mL of absolute ethanol, stir it magnetically to dissolve it, and obtain 4- Poly(4-vinylpyridine) / absolute ethanol solution with a vinylpyridine monomer concentration of 0.04mol / L.

[0026] (2) Preparation of FeCl 3 ·6H 2 O / dehydrated ethanol solution: take 1.08 g FeCl 3 ·6H 2 O was added to 50 mL of absolute ethanol, and magnetically stirred to dissolve it to obtain FeCl with a concentration of 0.08 mol / L 3 ·6H 2 O / absolute ethanol solution.

[0027] (3) Preparation of cross-linked complex precursor: FeCl 3 ·6H 2 Add O / dehydrated ethanol solution to poly-4-vinylpyridine / dehydrated ethanol solution, molar ratio (Fe 3+ : 4-vinylpyridine monomer = 2:1); continue to stir for 12 h to form a stable complex precipitation, then distill under reduced pressure at 60°C and vacuum dry at 120°C for 12 h to obt...

Embodiment 2

[0031]The experimental procedure of embodiment 2 is the same as that of embodiment 1, but the FeCl prepared in step (2) 3 ·6H 2 The concentration of O / absolute ethanol solution is 0.16 mol / L, and Fe in the cross-linked complex precursor prepared in step (3) 3+ The molar ratio to 4-vinylpyridine monomer is 4:1.

Embodiment 3

[0033] The experimental procedure of embodiment 3 is the same as that of embodiment 1, but the FeCl prepared in step (2) 3 ·6H 2 The concentration of O / dehydrated ethanol solution is 0.04 mol / L, and the Fe in the cross-linked complex precursor prepared in step (3) 3+ The molar ratio to 4-vinylpyridine monomer is 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com