High-strength polyester spunbonded non-woven quicklime desiccant packaging film and production method thereof

A technology of spun-bonded non-woven fabric and high-strength polyester, which is applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., which can solve the problems of poor water permeability, poor drying effect, and low tear strength and other problems, to achieve the effect of good gas passage performance, improved peel strength, and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

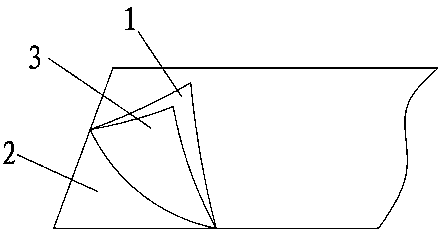

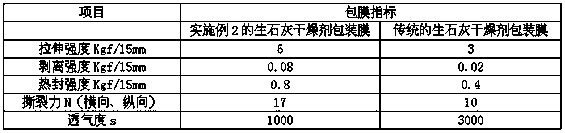

[0029] Example 1: Structure of high-strength polyester spunbonded non-woven quicklime desiccant packaging film

[0030] like figure 1 As shown, the high-strength polyester spunbond non-woven quicklime desiccant packaging film includes PET spunbond non-woven fabric 1 and milky white PE breathable film 2, and the PET spunbond non-woven fabric 1 and milky white PE breathable film 2 are glued by AD Compounded with agent 3 (polyurethane two-component adhesive), the PET spunbonded nonwoven fabric is a PET hot-pressed nonwoven fabric with a smooth surface or smooth on both sides, and the weight of the PET spunbonded nonwoven fabric 1 is 40-80g / m 2 , the surface of the material is smooth, and it is not easy to fluff when rubbed by hand. At the same time, the surface can be printed with water-based ink, and the text and pattern are clear; the air permeability of the milky white PE breathable film is 25-50g / M 2 , the breathable membrane not only has good air permeability, but also ha...

Embodiment 2

[0031] Embodiment 2: the production method of high-strength polyester spunbond non-woven quicklime desiccant packaging film

[0032] 1) Take the PET spunbonded nonwoven fabric and use flexographic water-based ink to print text and patterns on the surface to obtain PET spunbonded nonwoven fabric 1;

[0033] 2) Weigh the raw materials according to the following weight ratio: LDPE 15%, LLDPE 20%, MLLDPE 20%, elastomer PE 8% and calcium carbonate 37%, and produce milky white PE breathable film 2 through casting process;

[0034] 3) Corona treatment is carried out on the glued surface of the milky white PE breathable membrane 2, the corona condition is a voltage of 2KW, and the unwinding speed is 100m / min;

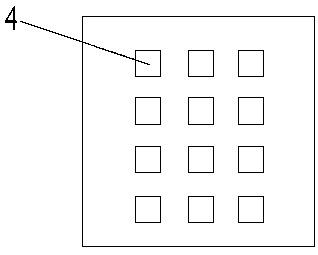

[0035] 4) Use a dry lamination machine with a three-stage or four-stage oven for dry lamination, and the mesh roll of the dry lamination adopts AD adhesive in a point-like interval, such as figure 2 As shown, a set of gluing areas 4 with a square structure is set on the surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| tear load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com