Metal enclosure made of thinned stainless steel sheet and welding process thereof

A technology of stainless steel plate and welding process, which is applied in the direction of metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of safety hazards, lifting and other problems, and achieve the effect of long durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

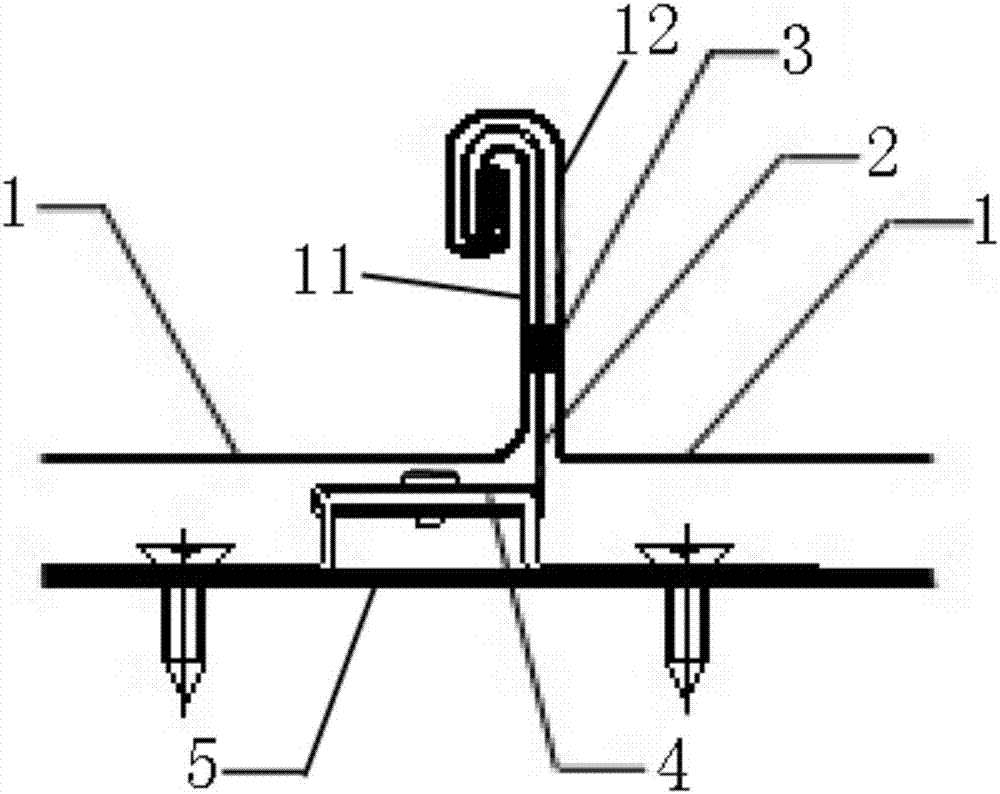

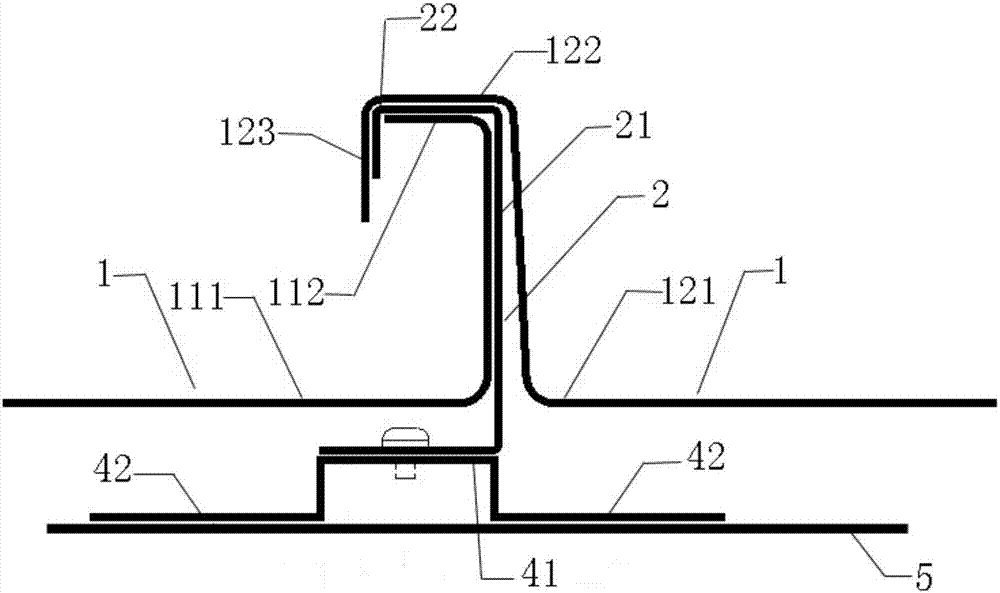

[0045] Such as figure 1 , 2 The metal enclosure of the thin stainless steel plate shown includes a roof panel 1, a thin fixed support 2, a weld 3, a base 4 and a roof structure layer 5. The roof panel 1 includes a first edge 11, a second edge 12 and The roof panel body 13 is arranged between the first edge 11 and the second edge 12, the base 4 is fixed on the roof structure layer 5, and the thin fixing support 2 is fixed on the base 4, The first edge 11 of the one roof panel 1 is attached to one side surface of the thin fixed support 2, and the second edge 12 of the other roof panel 1 is attached to the other side surface of the thin fixed support 2. A welding seam 3 is provided between the first edge 11 and the second edge 12 and the thin fixed support 2 respectively. Wherein, the base 4 includes a base body 41 with a π-shaped cross-section. The two ends of the base body 41 extend outward to form a base extension 42 which is fixed on the roof structure layer 5. In addition, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com