Rotary kiln thermal desorption device capable of uniformly heating materials

A uniform heating and rotary kiln technology, applied in the restoration of contaminated soil, etc., can solve problems such as poor temperature uniformity, achieve high-efficiency restoration, and reduce the effect of temperature inhomogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A rotary kiln thermal desorption device that can uniformly heat materials described in the present invention, the specific implementation is described as follows:

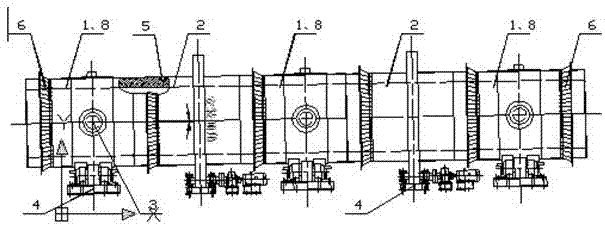

[0018] Such as figure 1 , figure 2 As shown, the present invention consists of a fixed section kiln body 1, a rotary section kiln body 2, a burner device 3, a supporting roller device 4, a kiln body insulation 5 and a sealing device 6. The rotary kiln that will be used for thermal desorption treatment is divided into several sections along the length direction according to the processing capacity requirements, that is, the rotary section kiln body 2 and the fixed section kiln body 1 are alternately combined.

[0019] The kiln body 2 in the rotary section rotates oriented (clockwise or counterclockwise) around the installation axis. Anti-blocking scrapers are installed inside and installed with a certain inclination angle, which can promote the continuous turning of materials in the kiln body and move in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com