Acid-alkali corrosion-resistant ultrasonic cleaning tank

A cleaning tank and ultrasonic technology, applied in the field of ultrasonic cleaning equipment, can solve the problems affecting the service and life of ultrasonic cleaning tanks, hidden in various dirt, poor corrosion resistance, etc., to achieve reuse, high vibration efficiency, and increased cleaning. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

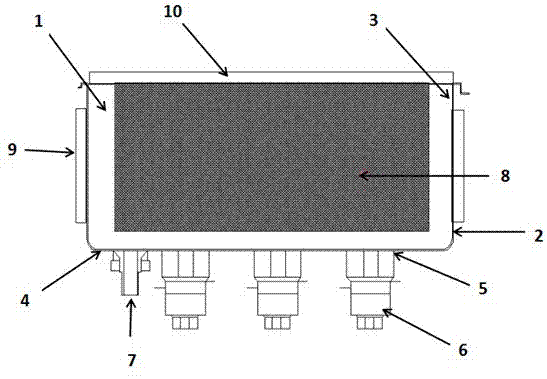

[0026] Such as figure 1 The anti-acid and alkali corrosion ultrasonic cleaning tank includes a cleaning tank body 1 and a piezoelectric ceramic ultrasonic transducer 6, and a vibrating plate 4 is arranged between the cleaning tank body 1 and the piezoelectric ceramic ultrasonic transducer 6 , the cleaning tank vibrating plate 4 is fixedly connected to the piezoelectric ceramic ultrasonic transducer 6 through studs combined with high-strength structural glue 5; the cleaning tank body 1 includes a stainless steel shell 2 and an anti-corrosion lining 3, The inner liner 3 is detachably fixed in the shell 2, and the inner cavity of the cleaning tank body 1 is also provided with a filter basket 8 for filtering dirt, and removing the filter basket 8 will remove the dirt in the cleaning solution. out. The shell 2 of the cleaning tank body 1 is made of SUS304 stainless steel, which has the characteristics of beautiful appearance, corrosion resistance, high temperature resistance, and ...

Embodiment 2

[0028] Such as figure 1 The anti-acid and alkali corrosion ultrasonic cleaning tank includes a cleaning tank body 1 and a piezoelectric ceramic ultrasonic transducer 6, and a vibrating plate 4 is arranged between the cleaning tank body 1 and the piezoelectric ceramic ultrasonic transducer 6, The cleaning tank vibrating plate 4 is fixedly connected to the piezoelectric ceramic ultrasonic transducer 6 through studs combined with high-strength structural glue 5; the cleaning tank body 1 includes a stainless steel shell 2 and an anti-corrosion lining 3, the The inner liner 3 is detachably fixed in the shell 2, and the inner cavity of the cleaning tank body 1 is also provided with a filter basket 8 for filtering dirt, and the dirt in the cleaning solution will be taken out when the filter basket 8 is removed. . The shell 2 of the cleaning tank body 1 is made of SUS304 stainless steel, which has the characteristics of beautiful appearance, corrosion resistance, high temperature res...

Embodiment 3

[0030] Such as figure 1The anti-acid and alkali corrosion ultrasonic cleaning tank includes a cleaning tank body 1 and a piezoelectric ceramic ultrasonic transducer 6, and a vibrating plate 4 is arranged between the cleaning tank body 1 and the piezoelectric ceramic ultrasonic transducer 6, The cleaning tank vibrating plate 4 is fixedly connected to the piezoelectric ceramic ultrasonic transducer 6 through studs combined with high-strength structural glue 5; the cleaning tank body 1 includes a stainless steel shell 2 and an anti-corrosion lining 3, the The inner liner 3 is detachably fixed in the shell 2, and the inner cavity of the cleaning tank body 1 is also provided with a filter basket 8 for filtering dirt, and the dirt in the cleaning solution will be taken out when the filter basket 8 is removed. . The shell 2 of the cleaning tank body 1 is made of SUS304 stainless steel, which has the characteristics of beautiful appearance, corrosion resistance, high temperature resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com