A step-by-step photocatalytic preparation method of tetrakis(p-sulfonic acid phenyl)porphyrin silver/silver/carbon nitride nanosheet composite material

A technology of p-sulfonic acid phenyl and composite materials, applied in chemical instruments and methods, material electrochemical variables, chemical/physical processes, etc., to achieve the effect of easy-to-obtain raw materials, low price, and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the content of the present invention easier to understand, the technical solutions of the present invention will be further described below in conjunction with specific embodiments, but the present invention is not limited thereto.

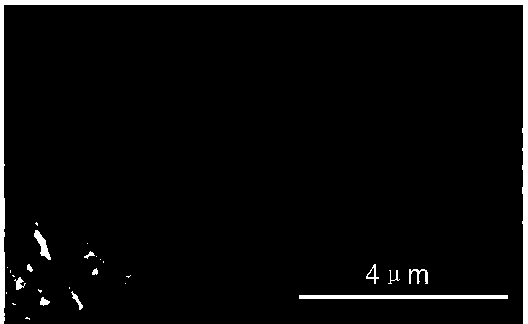

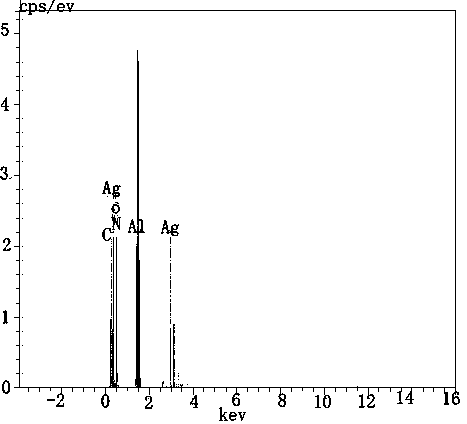

[0037] with C 3 N 4 Step-by-step photocatalytic preparation of AgTPPS for photocatalysts 4 / AgNPs / ng-C 3 N 4 The method for composite material, its concrete steps are:

[0038] 1) Add 30 mg ng-C 3 N 4 powder and 0.051 g AgNO 3 The solid was added to a 3:1 mixed solution of 20 ml ultrapure water and isopropanol, where isopropanol was used as a photogenerated hole capture agent. After ultrasonic treatment for 30 min, it was irradiated with ultraviolet-visible light for the first time for 60 min under the protection of nitrogen and stirring at room temperature at 800 rpm. 3 N 4 Photocatalytic reduction reaction for photocatalysts to form ng-C loaded with silver nanoparticles 3 N 4 suspension;

[0039] 2) Centrifuge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com