A nanoscale vacuum emulsification mixer

A technology of vacuum emulsification and mixer, which is applied in the direction of mixer accessories, mixers, chemical instruments and methods, etc. It can solve the problems that the micron level cannot be reached, and achieve the effect of improving the shearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation of the present invention will be further described below in conjunction with the examples.

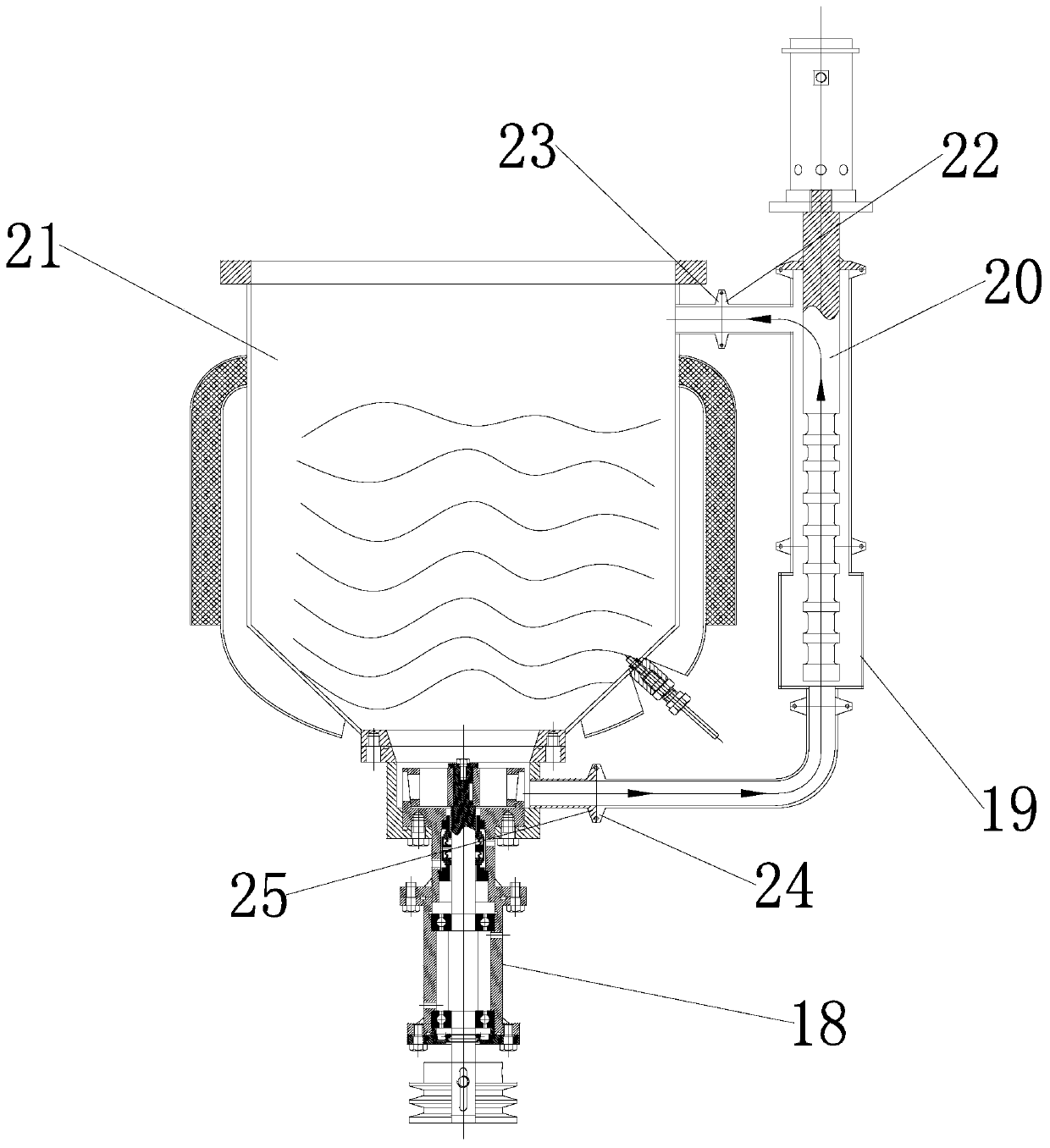

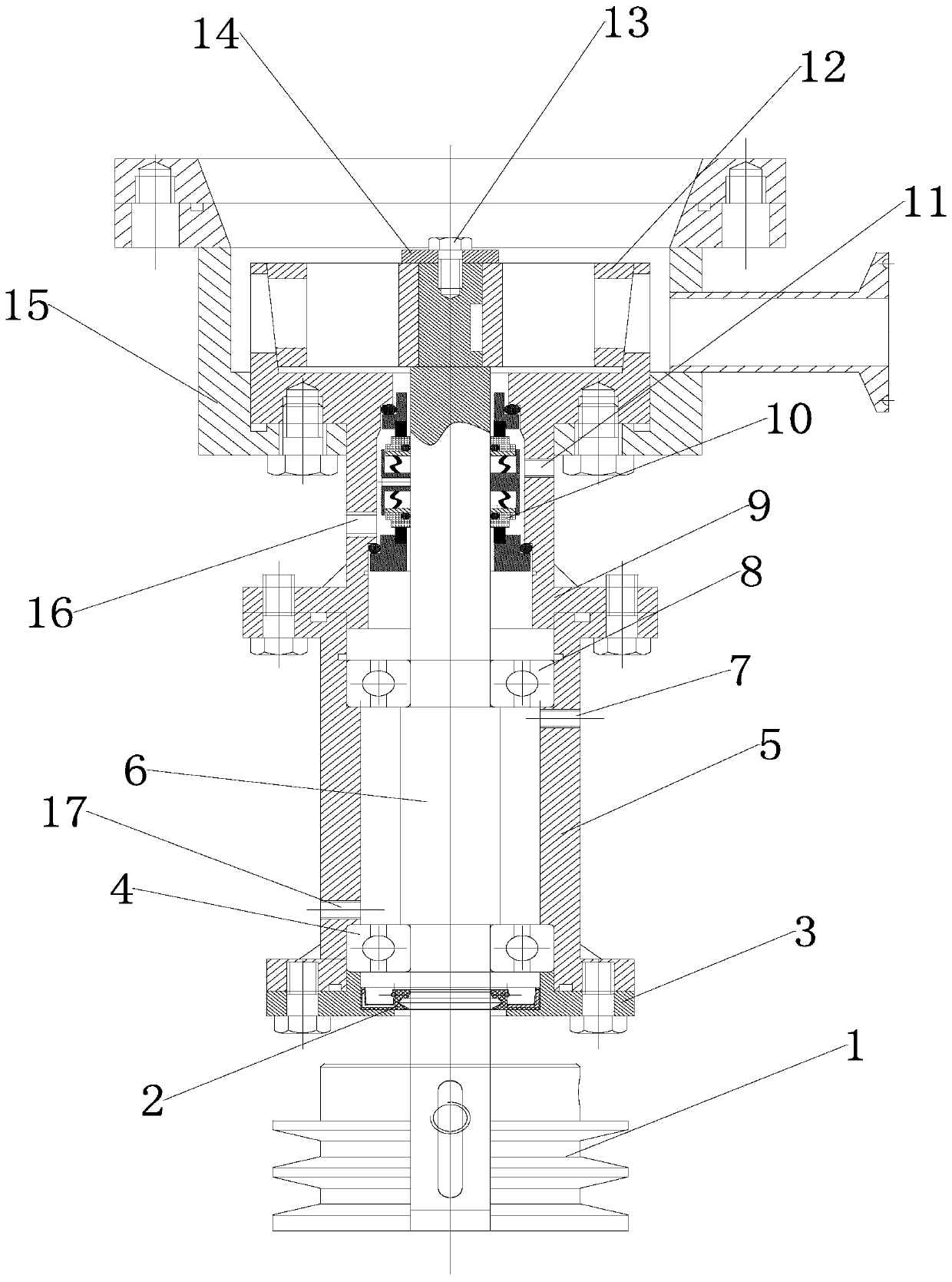

[0020] Such as Figure 1-2 As shown, a nanoscale vacuum emulsification mixer includes a homogeneous emulsification device 18, a material circulation pipeline 19, an ultrasonic generator 20, an emulsification pot 21,

[0021] The homogeneous emulsification device is connected to the bottom of the emulsification pot through a flange, the first chuck 22 on the material circulation pipeline is connected to the second chuck 23 on the upper end of the emulsification pot, the third chuck 24 on the material circulation pipeline and the homogeneous emulsification device The fourth chuck 25 on the side is connected, and the ultrasonic generating device is installed in the material circulation pipeline through the fifth chuck.

[0022] Wherein, the homogeneous emulsification device is a micron-scale homogeneous emulsification device.

[0023] The homogeneous e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com