Method for reducing loss of anthocyan of blueberry fruit juice in processing course

A blueberry juice and processing technology, which is applied in food science, sugary food ingredients, applications, etc., can solve the problems of decreased antioxidant effect, product quality, and discounted nutritional and health effects of blueberry juice.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

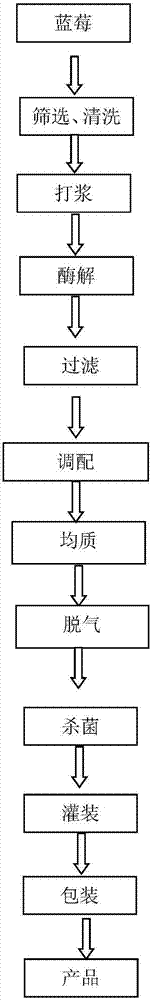

[0028] see figure 1 , a method for reducing the loss of anthocyanins in blueberry juice processing, which is carried out as follows:

[0029] 1. Select non-rotten blueberries, wash them, add 0.15% citric acid and 0.05% ascorbic acid, beat at a low speed of 400r / min, and control the temperature of the slurry below 40°C.

[0030] 2. Use citric acid to adjust the pH of the blueberry slurry to 3.0, add 0.02% zinc lactate, 0.02% malic acid, 0.01% glutathione, 0.10% tea polyphenols, and 0.10% grape to the blueberry slurry Seed extract, then add 0.01% compound enzyme of pectinase and glucoamylase, the mass ratio of pectinase and glucoamylase is 2:1, the enzyme activities are all greater than 20000U / g, and enzymatically hydrolyzed at 40°C for 90min.

[0031] 3. After the blueberry slurry is enzymatically hydrolyzed, filter it through a 150-mesh sieve, and add 5% sucrose, 1% lactose, 0.04% sodium citrate, 0.05% trehalose, and 0.04% β-cyclodextrin according to the mass ratio , 0.05% g...

Embodiment 2

[0037] A method for reducing anthocyanin loss during blueberry juice processing, which is carried out as follows:

[0038] 1. Select non-rotten blueberries, wash them, add 0.20% citric acid and 0.15% ascorbic acid, beat at a low speed of 500r / min, and control the temperature of the slurry below 40°C.

[0039] 2. Use citric acid to adjust the pH of the blueberry slurry between 3.5, add 0.04% zinc lactate, 0.06% malic acid, 0.03% glutathione, 0.20% tea polyphenols, and 0.20% grape Seed extract, then add 0.03% compound enzyme of pectinase and glucoamylase, the mass ratio of pectinase and glucoamylase is 2:1, the enzyme activity is greater than 20000U / g, and enzymatically hydrolyzed at 50°C for 120min.

[0040] 3. After the blueberry slurry is enzymatically hydrolyzed, filter it through a 200-mesh screen, add 8% sucrose, 2% lactose, 0.08% sodium citrate, 0.15% trehalose, and 0.06% β-cyclodextrin according to the mass ratio , 0.15% gum arabic, 0.10% xanthan gum, and 0.08% sodium c...

Embodiment 3

[0044]A method for reducing anthocyanin loss during blueberry juice processing, which is carried out as follows:

[0045] 1. Select non-rotten blueberries, wash them, add 0.17% citric acid and 0.10% ascorbic acid, beat at a low speed of 450r / min, and control the temperature of the slurry below 40°C.

[0046] 2. Use citric acid to adjust the pH of the blueberry slurry to 3.3, add 0.03% zinc lactate, 0.04% malic acid, 0.02% glutathione, 0.15% tea polyphenols, and 0.15% grape to the blueberry slurry Seed extract, then add 0.02% compound enzyme of pectinase and glucoamylase, the mass ratio of pectinase and glucoamylase is 2:1, and the enzyme activity is greater than 20000U / g, at 45 ℃, enzymatic hydrolysis for 100min.

[0047] 3. After the blueberry slurry is enzymatically hydrolyzed, filter it through a 180-mesh sieve, and add 7% sucrose, 1.5% lactose, 0.06% sodium citrate, 0.10% trehalose, and 0.05% β-cyclodextrin according to the mass ratio , 0.10% gum arabic, 0.08% xanthan gum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com