Speed regulating system and speed regulating method for switched reluctance motor

A technology of switched reluctance motor and speed control system, which is applied in control system, motor control, AC motor control, etc. It can solve the problems of speed control system out of step, failure of speed control ability, poor positioning ability, etc., to ensure stability , Guaranteed rigidity, simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

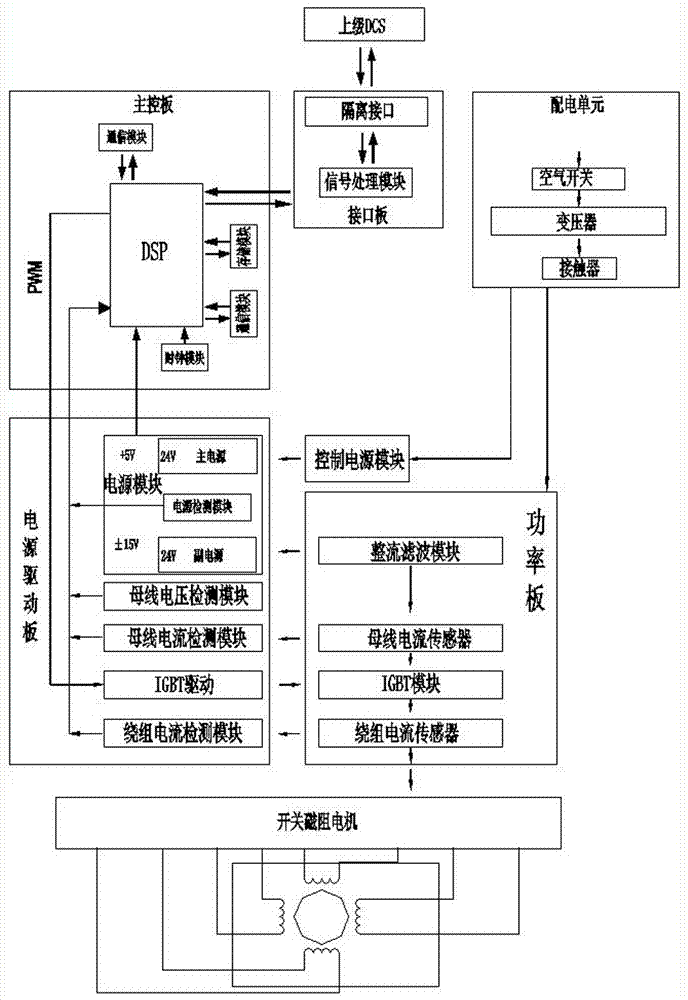

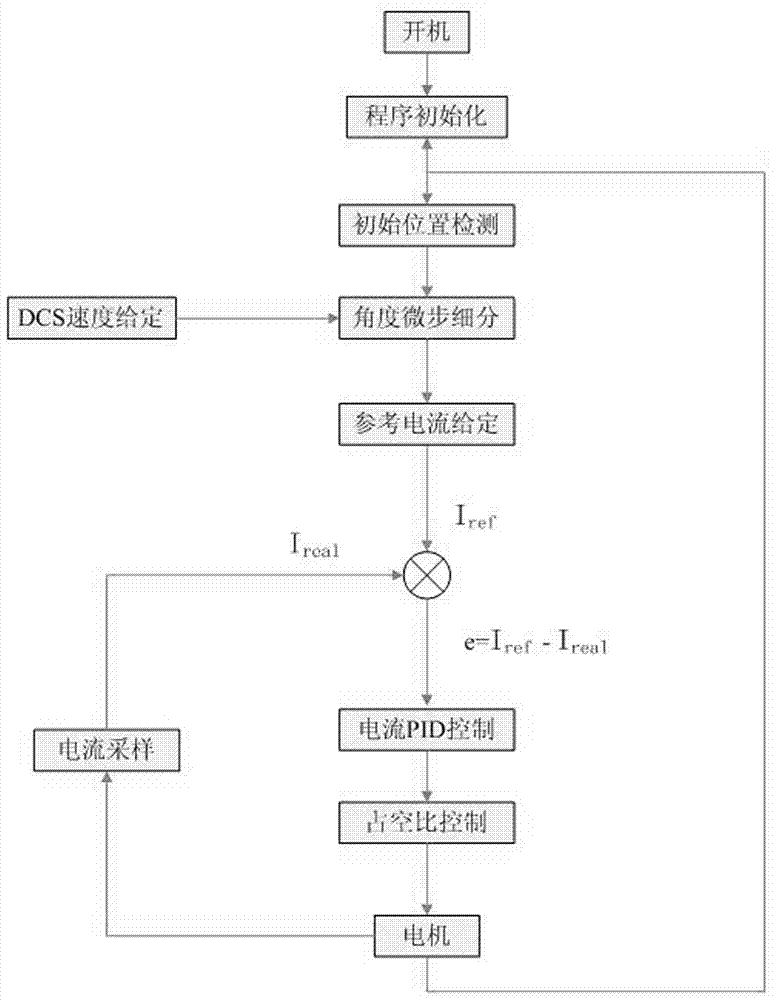

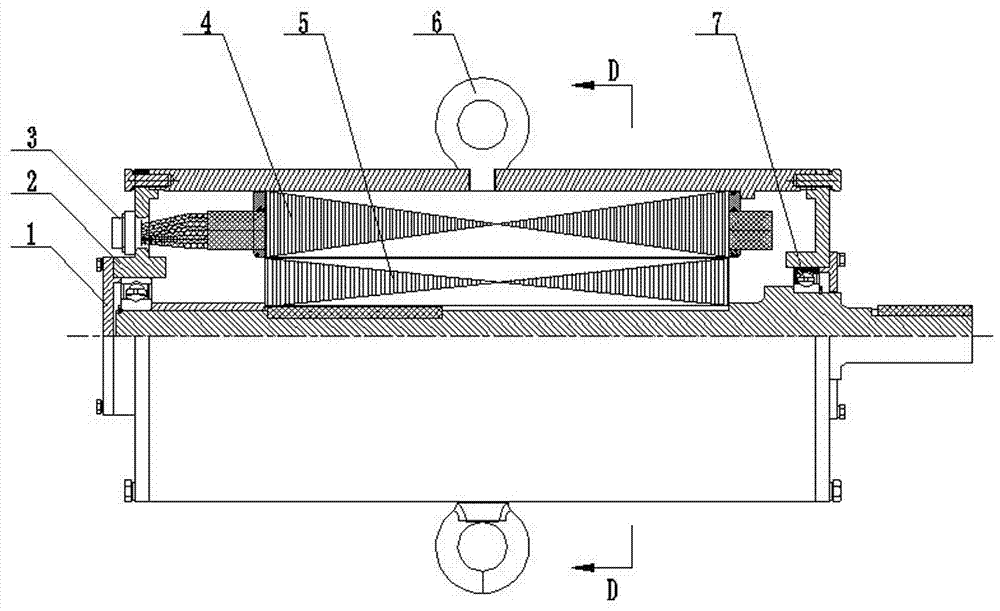

[0035] Such as figure 1 , image 3 , Figure 4 and Figure 5As shown, a switched reluctance motor speed control system includes a superior DCS (distributed control system), a switched reluctance motor and a controller. The switched reluctance motor described in this embodiment is a low-speed DC four-phase synchronous motor. The resistance motor includes bearing outer cover 1, end cover 2, connection terminal 3, stator 4, rotor 5, lifting ring 6 and bearing 7; the stator 4 of the switched reluctance motor includes a frame 11, a stator core 10 and a stator winding 9, and the switch magnetic The rotor 5 of the resistance motor includes a rotor core 8 and a rotating shaft. The rotor core 8 is integrally processed from a whole round steel instead of laminated silicon steel sheets. Although the speed of the motor will be limited, it has good rigidity and is easy to manufacture. And the price is cheap; two light holes 12 are radially processed on the rotor core 8, and the rotor co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com