Wafer edge defect detecting method

An edge defect and wafer technology, applied in the field of wafer edge defect detection, can solve the problems of slow detection speed and low accuracy, and achieve the effect of improving detection speed and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

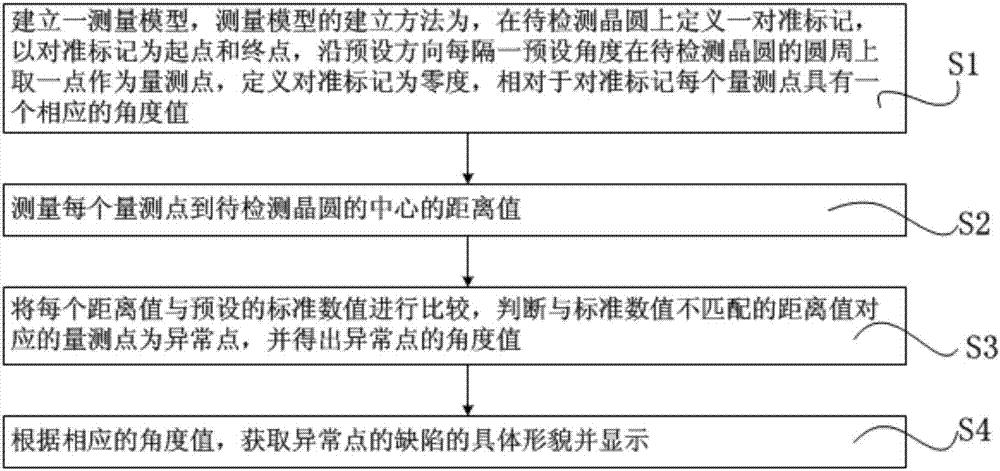

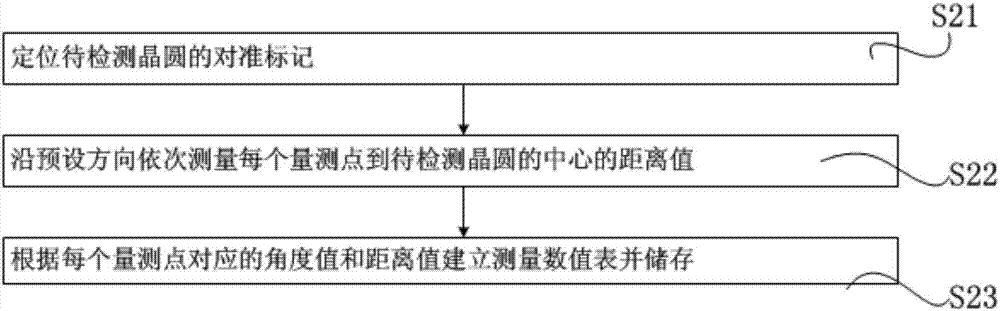

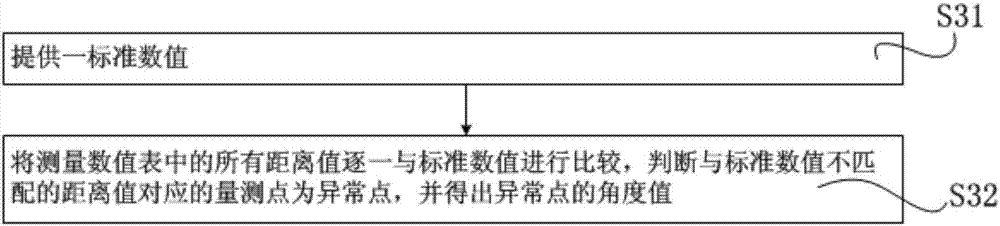

[0027] In a preferred embodiment of the present invention, as Figure 1-3 As shown, a method for detecting wafer edge defects is provided, comprising the following steps:

[0028] Step S1. Establish a measurement model. The method of establishing the measurement model is to define an alignment mark on the wafer to be inspected, with the alignment mark as the starting point and the end point, and place the alignment mark on the wafer to be inspected at every preset angle along the preset direction. Take a point on the circumference of the circle as the measurement point, define the alignment mark as zero degrees, and each measurement point has a corresponding angle value relative to the alignment mark;

[0029] Step S2, measuring the distance value from each measurement point to the center of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com