Manufacture method of intelligent bus card

A technology of an intelligent bus card and a manufacturing method, which is applied to record carriers, instruments, computer parts and other directions used by machines, can solve the problems of bus IC card shell breakage, small size of bus IC card, and bending and bending, etc. Good tightness, avoid metal fatigue, reduce the effect of distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

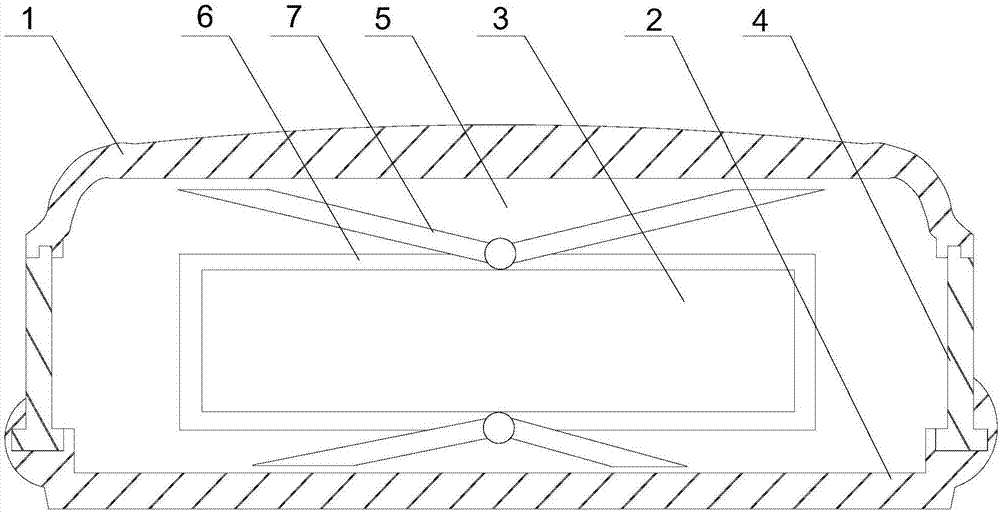

[0025] like figure 1 As shown, this embodiment includes the following steps:

[0026] (A) forming an upper shell 1 and a lower shell 2 capable of engaging with each other by injection molding in a mold;

[0027] (B) A support body 6 is fixedly installed in the lower casing 2, a chip 3 is placed in the support body 6, and a filler 5 is arranged around the support body 6, and the chip 3 is placed at the center of the lower casing 2;

[0028] (C) A V-shaped metal frame 7 is hingedly connected to the upper and lower ends of the support body 6, and a gap is left between the movable end of the V-shaped metal frame 7 and the upper shell 1 and the lower shell 2 respectively;

[0029] (D) The upper casing 1 and the lower casing 2 are connected and matched by the rubber block 4, and then the upper casing 1 and the lower casing 2 are bonded and sealed by an adhesive.

[0030] The work of the present invention is an improvement to the existing bus IC card shell, and the upper casing 1, ...

Embodiment 2

[0033] like figure 1 As shown, this embodiment is based on Embodiment 1. In step (C), the two V-shaped metal frames 7 are symmetrically arranged on the top and bottom surfaces of the support body 6 with the cavity as the center. Two V-shaped metal frames 7 are symmetrically arranged on the support body 6 with the cavity as the center, so that when the front or back of the IC card or the left end or the right end is subjected to external force, the V-shaped metal frame 7 can make the same direction. Deformation reaction to reduce the degree of distortion of the card surface and avoid damage to the chip 3 in the support body 6 .

[0034] Preferably, the filler 5 is foamed plastic. The foamed plastic is light in weight and has good tightness. When it is filled into the cavity together with the V-shaped metal frame 7, it can ensure that the V-shaped metal frame 7 is provided with a certain support, and at the same time, it can also make the V-shaped bracket deform freely, avoidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com