Separation method of boron in gypsum mineral and/or hard gypsum mineral and measurement method of boron isotope

A separation method and technology of anhydrite, applied in the direction of measuring devices, analysis materials, preparation of test samples, etc., can solve problems such as ineffective dissolution, separation and extraction, unfavorable analysis and application of boron isotope composition characteristics, and the impact of recovery on mass spectrometry analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] The present embodiment provides a method for separating boron in gypsum minerals, comprising the following steps:

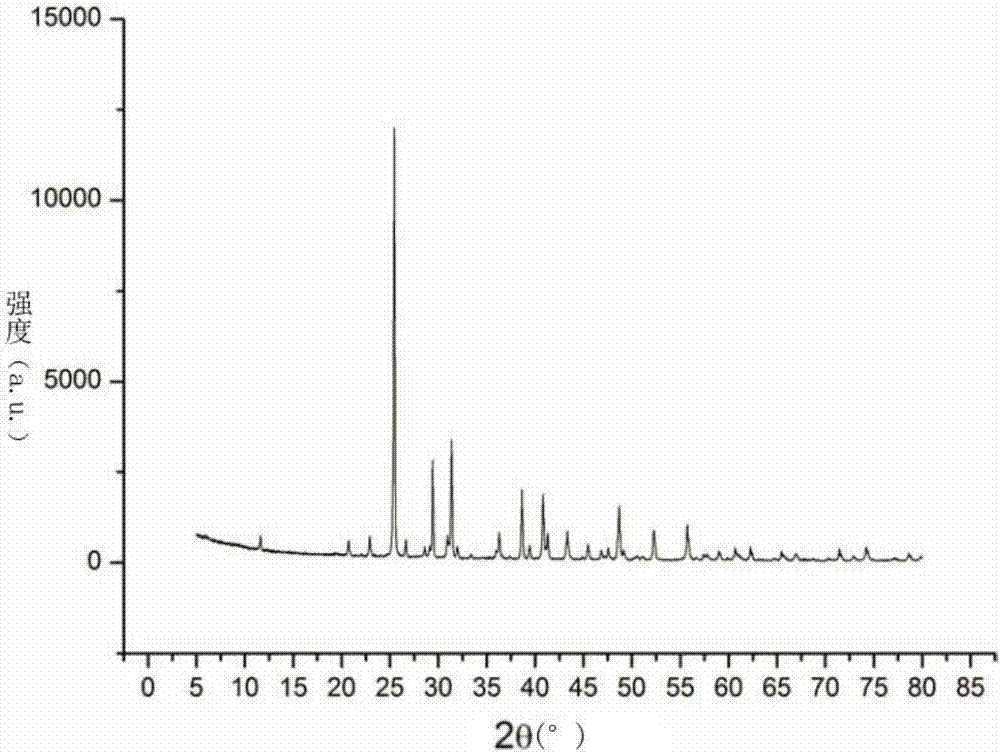

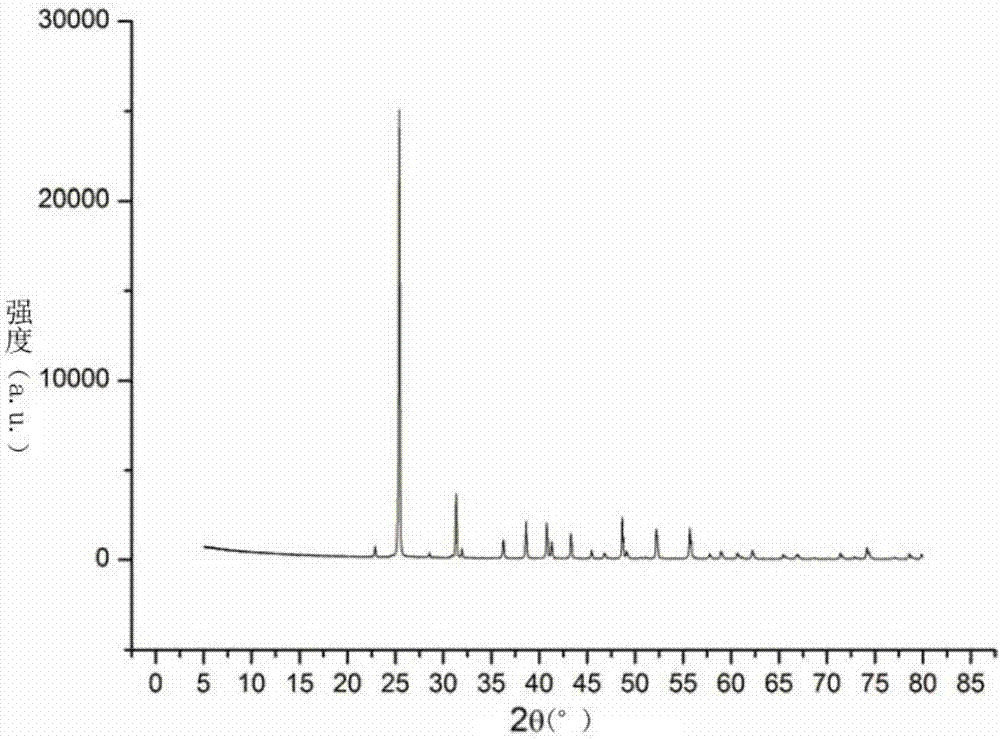

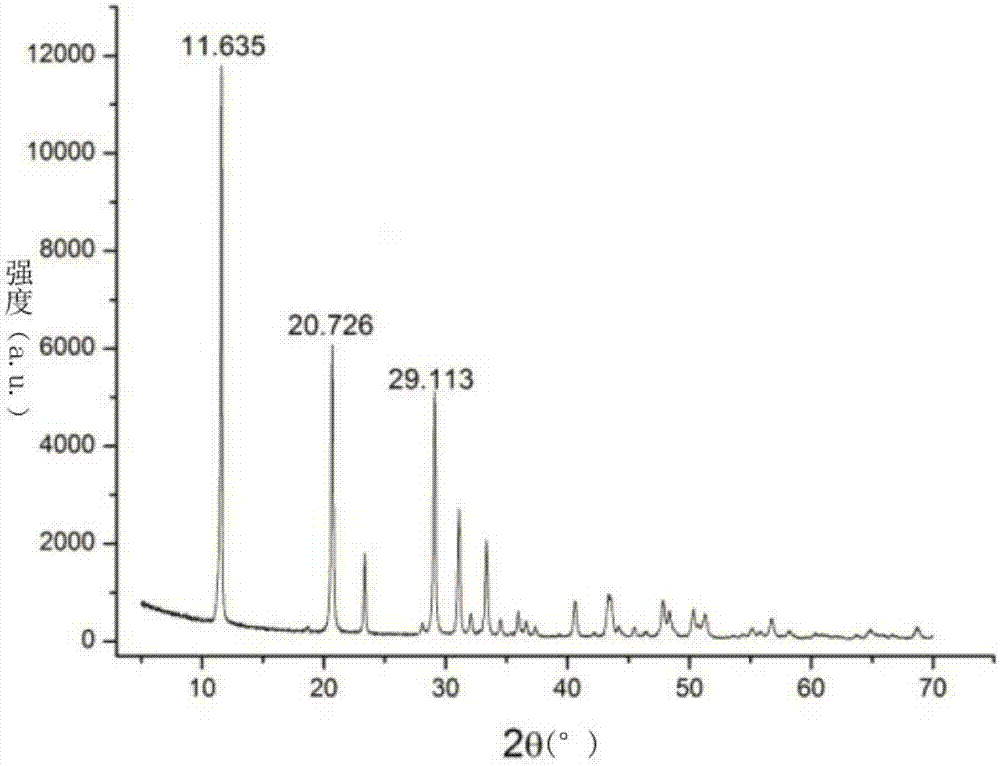

[0035] Purification: use sodium metatungstate monohydrate to prepare a specific gravity of 2.31g / cm 3 The heavy liquid, the impure gypsum mineral sample and the above heavy liquid are fully stirred in a polyethylene centrifuge tube, and then centrifuged in a centrifuge with a speed of 2000r / min for 10min, and the centrifuged gypsum mineral sample is deboronized After quick washing with water, dry at 40°C in an oven, and then perform XRD diffraction analysis until the mass percentage of gypsum in the gypsum mineral sample is 98% to 100%;

[0036] Reaction: Take 1g of the purified gypsum mineral sample and place it in the first polyethylene centrifuge tube, add 2g of ammonium bicarbonate and 10mL of boron-deionized water to it for reaction, and obtain the first supernatant and precipitate after the reaction. A supernatant is placed in a second polyethylene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com