Anchor stock structure with expanded head

A technology for enlarging head and anchor rod, which is applied in the direction of foundation structure engineering, sheet pile wall, protective device, etc., can solve the problems of low pull-out resistance of anchor rod, insufficient anchoring force, serious underground pollution, etc., and achieve the solution of insufficient anchoring force, The effect of convenient construction and less grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

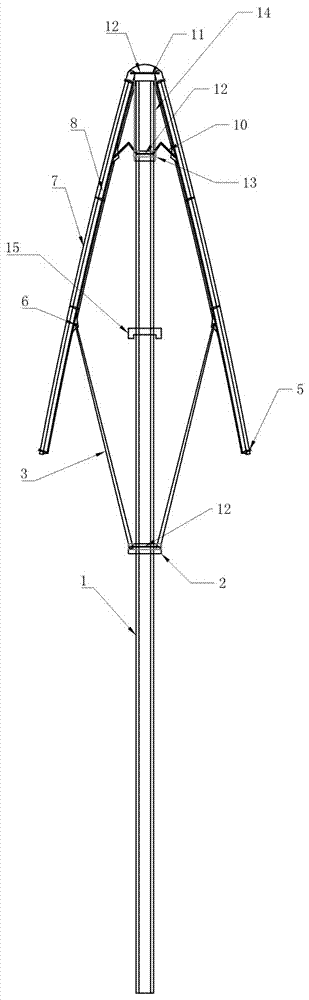

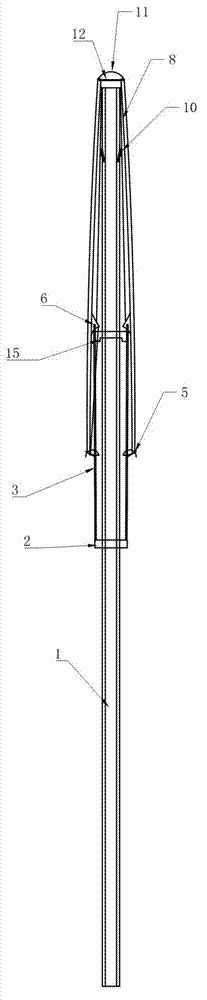

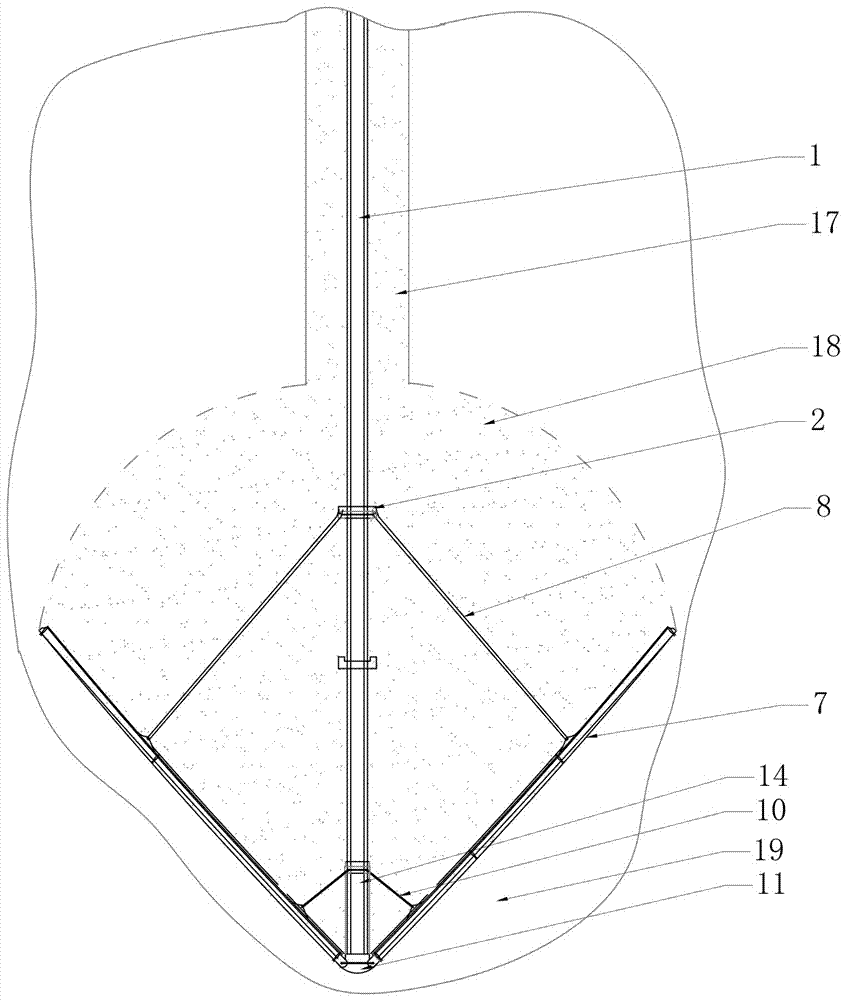

[0013] See attached figure 1 , the present invention consists of an anchor rod 1, a slider 2, a lower strut 3, an umbrella buckle 5, a hinge structure 6, an umbrella surface 7, an umbrella rib 8, an upper strut 10, an umbrella cap 11, a hinge seat groove 12, and a sleeve 14 And limit collar 15 forms. The slider 2 is a steel ring sleeve with several hinge seat grooves 12 on the outer circumference. The slider 2 is set on the anchor rod 1 and is slidingly connected with the anchor rod 1. The slider 2 and the lower support rod 3 are Hinged; the upper and lower ends of the sleeve 14 are provided with discs with several hinge seat grooves 12 on the outer circumference, and the sleeve 14 is fixed on the top of the anchor rod 1 by the umbrella cap 11; 3 and the umbrella rib 8 are made of angle steel, and one end of the lower strut 3 is hinged with the lower part of the umbrella rib 8 by the hinge structure 6, and the other end is arranged on the hinge seat groove 12 of the slider 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com