Method for producing small molecular dextran, product and application thereof

A technology for dextran and dextranase, applied in biochemical equipment and methods, medical preparations containing active ingredients, glycosylase, etc. Improvement and other issues, to achieve the effects of slowing down product inhibition, improving yield and purity, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

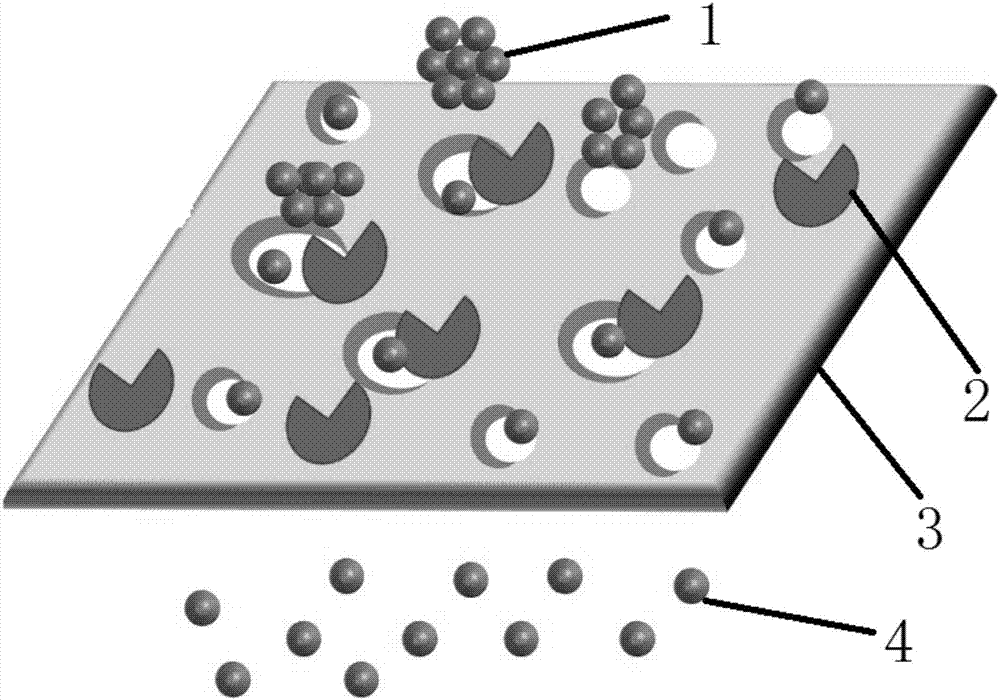

[0050] A method for producing small molecule dextran, such as figure 1 As shown, the specific steps are as follows:

[0051] (1) Add a dextranase solution with a pH of 5 and a concentration of 0.01 g / L into a polyacrylonitrile roll-type ultrafiltration membrane system with a molecular weight cut-off of 10,000 Da, and perform filtration and concentration treatment at an operating pressure of 1.0 MPa and a temperature of 30° C. Such as figure 2 As shown, the dextranase 2 is completely adsorbed on the surface of the ultrafiltration membrane 3 or in the membrane pores; an enzyme membrane reactor is obtained;

[0052] (2) Add pH=5.5, concentration is 100g / L, the solution of the dextran raw material 1 that weight-average molecular weight is 20000Da in the enzymatic membrane reactor gained in step (1), at operating pressure is 0.6MPa, temperature is to carry out under 50 ℃ After filtration, the small molecule dextran product 4 in the permeate was collected, and its average molecul...

Embodiment 2

[0055] A method for producing small molecule dextran, the steps are as follows:

[0056] (1) Add a dextranase solution with a pH of 7 and a concentration of 0.1g / L into a polyethersulfone tubular ultrafiltration membrane system with a molecular weight cut-off of 30,000Da, and perform filtration and concentration treatment at an operating pressure of 0.4MPa and a temperature of 20°C. The dextranase is completely adsorbed on the surface of the ultrafiltration membrane or in the pores of the membrane to obtain an enzyme membrane reactor;

[0057] (2) Add pH=6, concentration is 50g / L, the dextran solution that weight-average molecular weight is 40000Da in the enzymatic membrane reactor gained in step (1), at operating pressure be 0.4MPa, temperature is to filter under 37 ℃, collect The average molecular weight of the small molecule dextran product in the permeate solution is 5100 Da, and the molecular weight distribution breadth index is 1.8. Under the same conditions, the averag...

Embodiment 3

[0060] A method for producing small molecule dextran, the steps are as follows:

[0061] (1) First, add a dextranase solution with a pH of 9 and a concentration of 1 g / L into a polysulfone flat-panel ultrafiltration membrane system with a molecular weight cut-off of 50,000 Da, and carry out filtration and concentration treatment at an operating pressure of 0.1 MPa and a temperature of 50°C, so that the dextran The enzyme is completely adsorbed on the surface of the ultrafiltration membrane or in the pores of the membrane to obtain an enzyme membrane reactor;

[0062] (2) Add pH=7.5, concentration is 10g / L, the dextran solution that weight-average molecular weight is 70000Da to the enzymatic membrane reactor gained in step (1), at operating pressure be 0.1MPa, temperature is to filter under 20 ℃, collect The average molecular weight of the small molecule dextran product in the permeate solution was 7000 Da, and the molecular weight distribution breadth index was 1.8. Under the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com