Gasoline additive and production method thereof

A technology of gasoline additives and combustion accelerants, applied in the field of gasoline additives, which can solve the problems of not solving the problem of full utilization of fuel by the engine, not fundamentally promoting the combustion of fuel, and not completely preventing oil stains and carbon deposits, etc., to achieve a good combustion promotion effect , good detergency, emission reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

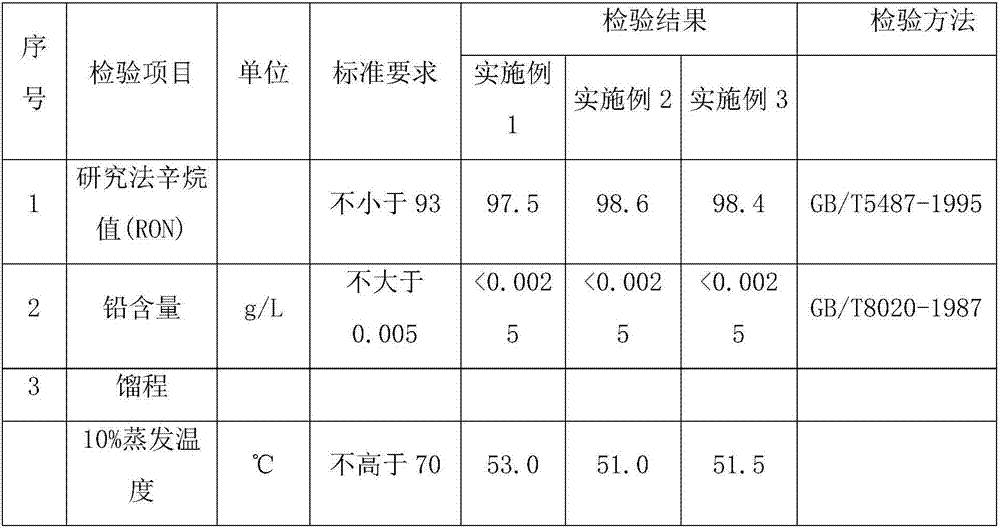

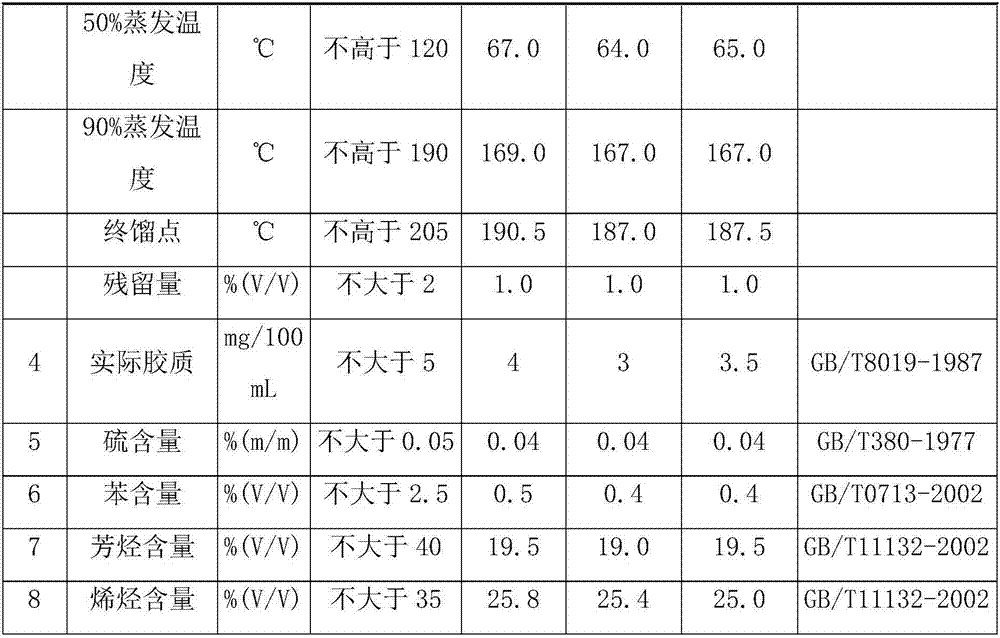

Embodiment 1

[0029] Add 0.01kg of nano-zinc powder with an average particle size of 20nm and 0.01kg of nano-zirconium powder with an average particle size of 20nm into the ethanol solution of ethylenediamine, heat to 55°C, stir for 30 minutes, and the stirring speed is 100r / min. Mix evenly, cool down to room temperature, and prepare nanoparticle complexes; the obtained nanoparticle complexes are added to 60 kg of absolute ethanol, and then successively add 7 g of methanol, 5 kg of Tween 80, 5 kg of Span 60, and 10 kg of Nitromethane, 20 kg of ferrocene and 2 kg of methyl tert-butyl ether were stirred at room temperature for 120 minutes at a stirring speed of 100 r / min, and the remaining nano gasoline additive was obtained after mixing evenly.

Embodiment 2

[0031] 0.01kg of nano-zinc powder with an average particle diameter of 30nm and 0.03kg of nano-zirconium powder with an average particle diameter of 20nm were added to the ethanol solution of ethylenediamine, heated to 40°C, stirred for 30 minutes, and the stirring speed was 100r / min. Mix evenly, cool down to room temperature, and prepare nanoparticle complexes; the obtained nanoparticle complexes are added to 70 kg of absolute ethanol, and then sequentially add 8 g of methanol, 4 kg of Tween 60, 6 kg of Span 80, and 15 kg of Nitromethane, 15 kg of ferrocene and 1.5 kg of ethyl tert-butyl ether were stirred at room temperature for 90 minutes at a stirring speed of 100 r / min, and the remaining nano gasoline additive was obtained after mixing evenly.

Embodiment 3

[0033] Add 0.02kg of nano zinc-zirconium alloy powder with an average particle size of 20nm to the ethanol solution of diethanolamine, heat to 40°C, stir for 50 minutes at a stirring speed of 100r / min, mix evenly, and cool to room temperature to obtain nanoparticles Complexes; the obtained nanoparticle complexes were added to 70kg of absolute ethanol, followed by 8g of methanol, 6kg of Tween 80, 4kg of Span 80, 20kg of nitromethane, 10kg of ferrocene and 1.5kg of The ethyl tert-butyl ether was stirred at room temperature for 90 minutes at a stirring speed of 100 r / min, and the remaining nano gasoline additive was obtained after mixing evenly.

[0034] The method for using the gasoline additive is as follows: the ratio of the prepared gasoline additive in gasoline is 500ppm-1000ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com