A kind of preparation method of natural antibacterial edible film

A natural antibacterial and probiotic technology, applied in the field of preparation of natural antibacterial edible film, can solve the problems of no antibacterial effect, no probiotic effect, single antibacterial effect, etc. The effect of antibacterial function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of preparation method of natural antibacterial edible film of the present invention comprises the steps:

[0027] (1) Lactobacillus acidophilus with probiotic activity is inoculated in the fermentation medium at an inoculum size of 1% (v / v), and cultivated at a constant temperature for 24 hours at a temperature of 37° C. to obtain a Lactobacillus acidophilus fermentation liquid, The final bacterial concentration is (0.5~5)×10 9 CFU / ml; and mix evenly, which can be mixed evenly by shaking the flask;

[0028] (2) Add 2 g of cellulose sodium sulfate powder and 0.3 g of glycerin to 85 ml of distilled water, and stir for 2 hours under sterile and room temperature conditions to obtain a cellulose sodium sulfate solution, which is the base membrane solution; in this base membrane solution, cellulose The weight ratio of sodium sulfate (ie edible film substrate) is 2.3%, and the weight ratio of glycerol (ie plasticizer) is 0.34%;

[0029] (3) In the cellulose sodium sul...

Embodiment 2

[0036] (1) Lactobacillus acidophilus with probiotic activity is inoculated in the fermentation medium at an inoculum size of 1% (v / v), and cultivated at a constant temperature at a temperature of 37°C for 24h to prepare a Lactobacillus acidophilus fermentation liquid, The final bacterial concentration is (0.5~5)×10 9 CFU / ml, and mix evenly, can be mixed evenly by shaking the bottle;

[0037] (2) Add 2 g of carboxymethyl cellulose powder and 0.3 g of glycerin to 80 ml of distilled water, and stir for 2 hours under sterile and room temperature conditions to obtain a carboxymethyl cellulose solution, which is the base membrane solution; in this base membrane solution, The weight ratio of carboxymethylcellulose (i.e. edible film substrate) is 2.4%, and the weight ratio of glycerol (i.e. plasticizer) is 0.36%;

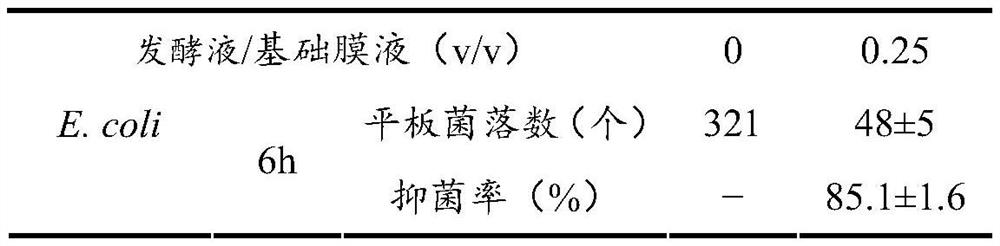

[0038] (3) In the carboxymethylcellulose solution prepared in step (2), add the Lactobacillus acidophilus fermentation broth after mixing evenly of 0.25 times the volume o...

Embodiment 3

[0043] (1) Inoculate Lactobacillus reuteri with probiotic activity into the fermentation medium at an inoculum size of 1% (v / v), and cultivate at a constant temperature of 37°C for 24 hours to obtain Lactobacillus reuteri fermentation solution, the final bacterial concentration is (0.8~9)×10 9 CFU / ml, and mix evenly, can be mixed evenly by shaking the bottle;

[0044] (2) Add 2 g of cellulose sodium sulfate powder and 0.3 g of glycerin to 85 ml of distilled water, and stir for 2 hours under sterile and room temperature conditions to obtain a cellulose sodium sulfate solution; The weight ratio of edible film substrate) is 2.3%, and the weight ratio of glycerol (i.e. plasticizer) is 0.34%;

[0045] (3) Add 0.17 times the volume of the base membrane liquid to the cellulose sodium sulfate solution prepared in step (2) and mix homogeneously with Lactobacillus reuteri fermentation broth, stir for 10min under aseptic and room temperature conditions, and then vacuum Degassing to pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com