Preparation method of isopropyl acetoacetate

A technology of isopropyl acetoacetate and isopropanol, which is applied in the field of preparation of pesticides and pharmaceutical synthetic raw materials, can solve the problems of low product yield, high cost, low yield, etc., to improve reaction yield and reduce the amount of waste , Improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

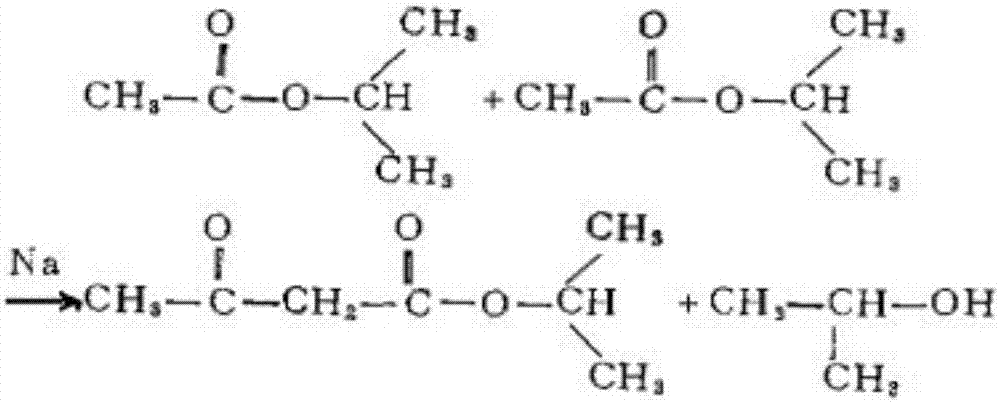

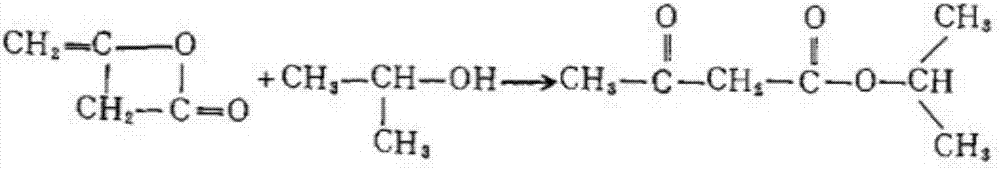

Method used

Image

Examples

Embodiment 1

[0021] Add 160g of isopropanol and 0.104g of catalyst into the reaction kettle, start stirring, add 208g of diketene dropwise into the reaction kettle, keep the temperature of the reaction process at 60±20°C, keep warm for 0.5h after the addition of diketene is completed, and obtain acetoacetate iso The crude propyl ester is obtained after rectification, with a yield of 93.5% and a product purity of 98.5%.

Embodiment 2

[0023] Add 160g of isopropanol and 0.024g of catalyst into the reaction kettle, start stirring, drop 240g of diketene into the reaction kettle, keep the temperature of the reaction process at 60±20°C, keep warm for 0.5h after the addition of diketene is completed, and obtain acetoacetate iso The crude propyl ester is obtained after rectification, with a yield of 93.2% and a product purity of 98.4%.

Embodiment 3

[0025] Add 160g of isopropanol and 1.12g of catalyst into the reaction kettle, start stirring, add 224g of diketene dropwise into the reaction kettle, keep the temperature of the reaction process at 60±20°C, keep warm for 0.5h after the addition of diketene is completed, and obtain isoacetoacetate The crude propyl ester is obtained after rectification, with a yield of 93.7% and a product purity of 98.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com