Method for preparing high-specific surface area precipitated calcium carbonate

A technology of precipitated calcium carbonate and high specific surface area, applied in calcium carbonate/strontium/barium, chemical instruments and methods, calcium/strontium/barium compounds, etc., can solve the problem of low calcium hydroxide concentration, difficult industrial application, and water resource consumption Large and other problems, to achieve high desulfurization efficiency, low production costs, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

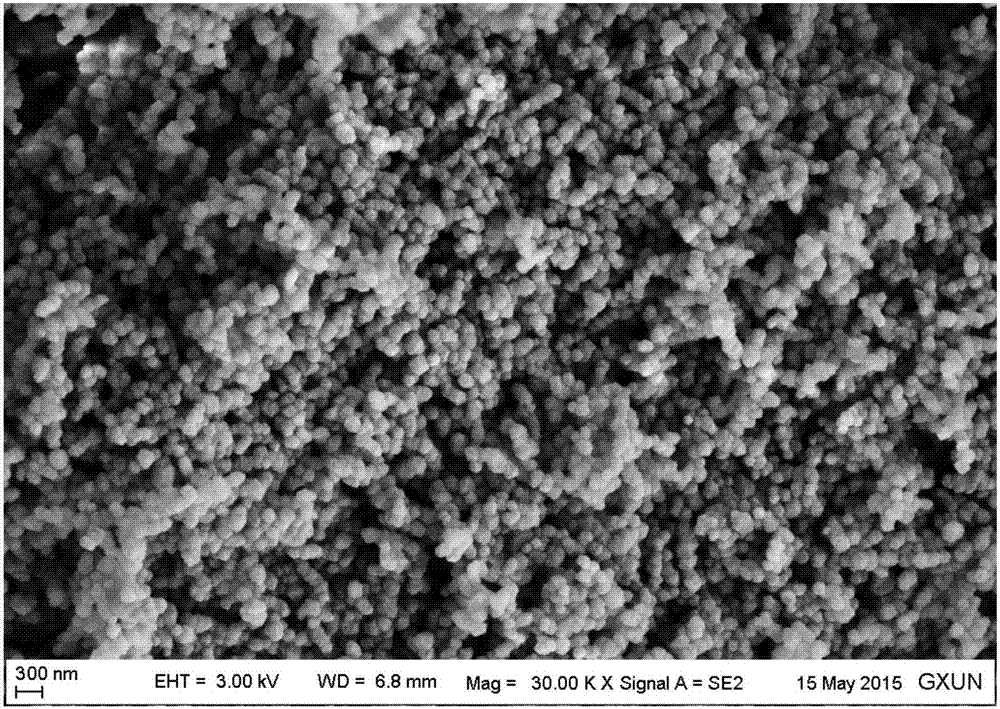

Image

Examples

preparation example Construction

[0029] The present embodiment relates to a kind of preparation method of precipitated calcium carbonate, the precipitated calcium carbonate of preparation has high specific surface area, specifically comprises the following steps:

[0030] Step 1. The quicklime obtained by calcination in the vertical kiln and the digested water are configured according to the ratio of 1:4 to 1:6 in mass ratio, and the digestion reaction is carried out. Impurities are removed, and the mesh number of the selected vibrating screen is gradually increased, and calcium hydroxide fine pulp is obtained after screening;

[0031] Step 2. Transport the fine calcium hydroxide slurry to a peeling machine for grinding for 30-60 minutes. The grinding medium is zirconium beads of 2-4 mm. After the grinding is completed, pass through a 200-mesh vibrating screen for impurity removal;

[0032] Step 3. Adjust the concentration of the ground calcium hydroxide slurry to 6-10%, cool the temperature to 15-20°C, and t...

Embodiment 1

[0038] Through the parameter setting of this embodiment, the specific surface area can be prepared to be 83.6m 2 The precipitated calcium carbonate of / g specifically comprises the following steps:

[0039] Step 1, the quicklime obtained by calcining the vertical kiln with 0.5% CaCl 2 The digested water is configured according to the mass ratio of 1:5. The temperature of the digested water is 70°C, and the digestion reaction is carried out. After the reaction is completed, the impurity is removed through 100 mesh, 200 mesh, and 320 mesh vibrating sieves. Calcium serum;

[0040] Step 2. Transport the fine calcium hydroxide slurry to a flake machine for grinding for 45 minutes. The grinding medium is zirconium beads of 2 mm. After the grinding is completed, pass through a 200-mesh vibrating sieve for impurity removal;

[0041] Step 3: Adjust the concentration of the ground calcium hydroxide slurry to 6%, cool the temperature to 15°C, and transport to 40m 3 In the carbonizatio...

Embodiment 2

[0044] Through the parameter setting of this embodiment, the specific surface area can be prepared to be 67.3m 2 The precipitated calcium carbonate of / g specifically comprises the following steps:

[0045] Step 1, the quicklime obtained by calcining the vertical kiln with 0.5% CaCl 2 The digested water is configured according to the mass ratio of 1:5. The temperature of the digested water is 70°C, and the digestion reaction is carried out. After the reaction is completed, the impurity is removed through 100 mesh, 200 mesh, and 320 mesh vibrating sieves. Calcium serum;

[0046] Step 2. Transport the fine calcium hydroxide slurry to a peeling machine for grinding for 30 minutes. The grinding medium is zirconium beads of 2 mm. After the grinding is completed, pass through a 200-mesh vibrating sieve for impurity removal;

[0047] Step 3. Adjust the concentration of the ground calcium hydroxide slurry to 8%, cool the temperature to 15°C, and transport it to 40m 3 In the carboni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com