A control system and control method for a fully automatic carton packaging machine

A control system and packaging machine technology, applied in the directions of automatic packaging control, packaging, packaging protection, etc., can solve the problems of difficult batch packaging, no cardboard forming into cartons, small space occupation, etc., and achieve good linearity and load adjustment characteristics , simple structure and convenient setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0059] A control system of a fully automatic carton packaging machine in this embodiment includes a packaging machine part and a control system part. In the packaging machine part, the cardboard structure used in the packaging can be used as follows: Figure 9 The cardboard structure shown, the cardboard has the cardboard front panel A, the cardboard bottom panel B, the cardboard back panel C and the cardboard top panel D connected in sequence, and the cardboard front panel Flap panels E are arranged on both sides of the panel D, and a section of adhesive strip F is also arranged at the end of the cardboard front panel A. The above-mentioned cardboard is processed in advance.

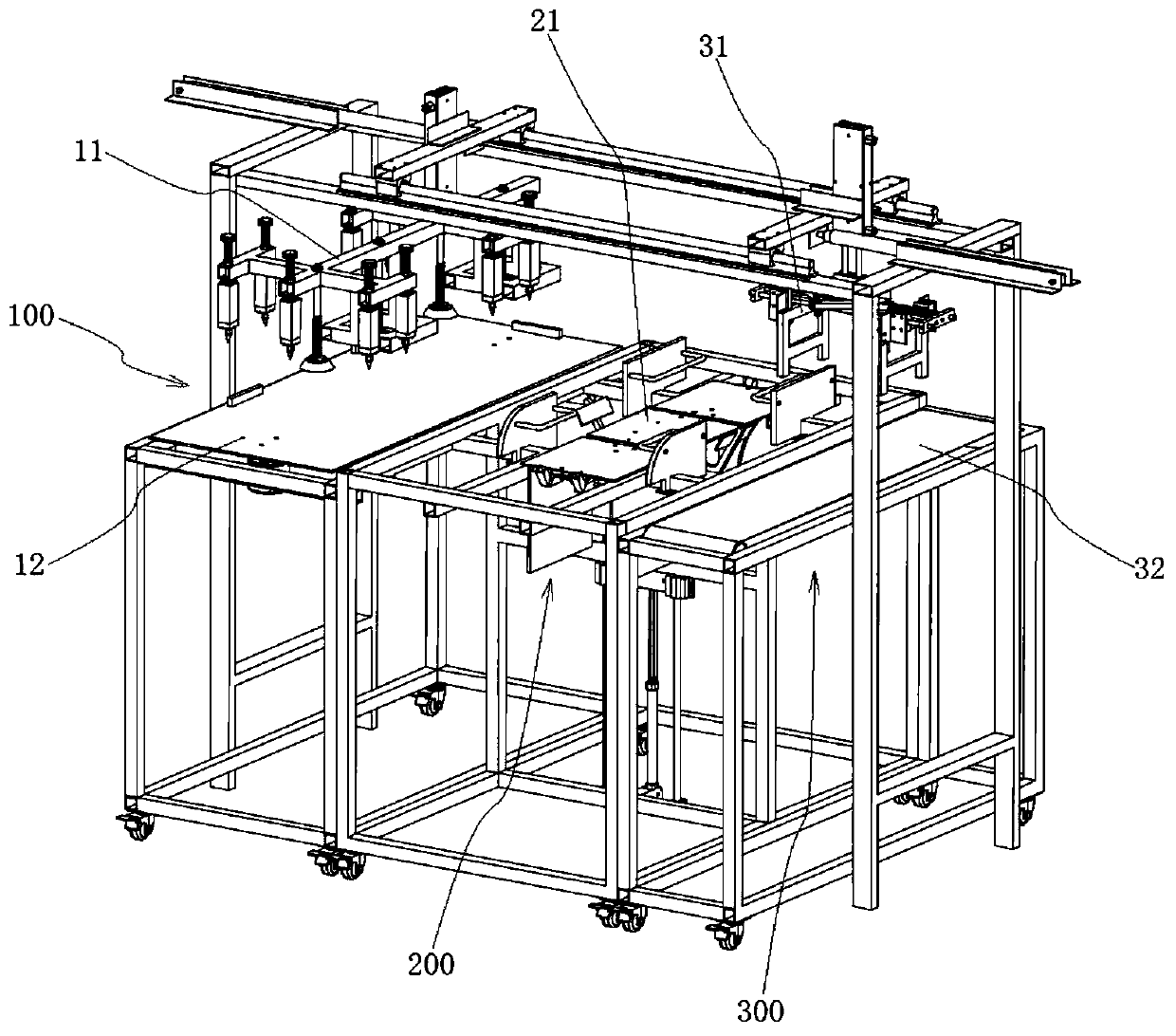

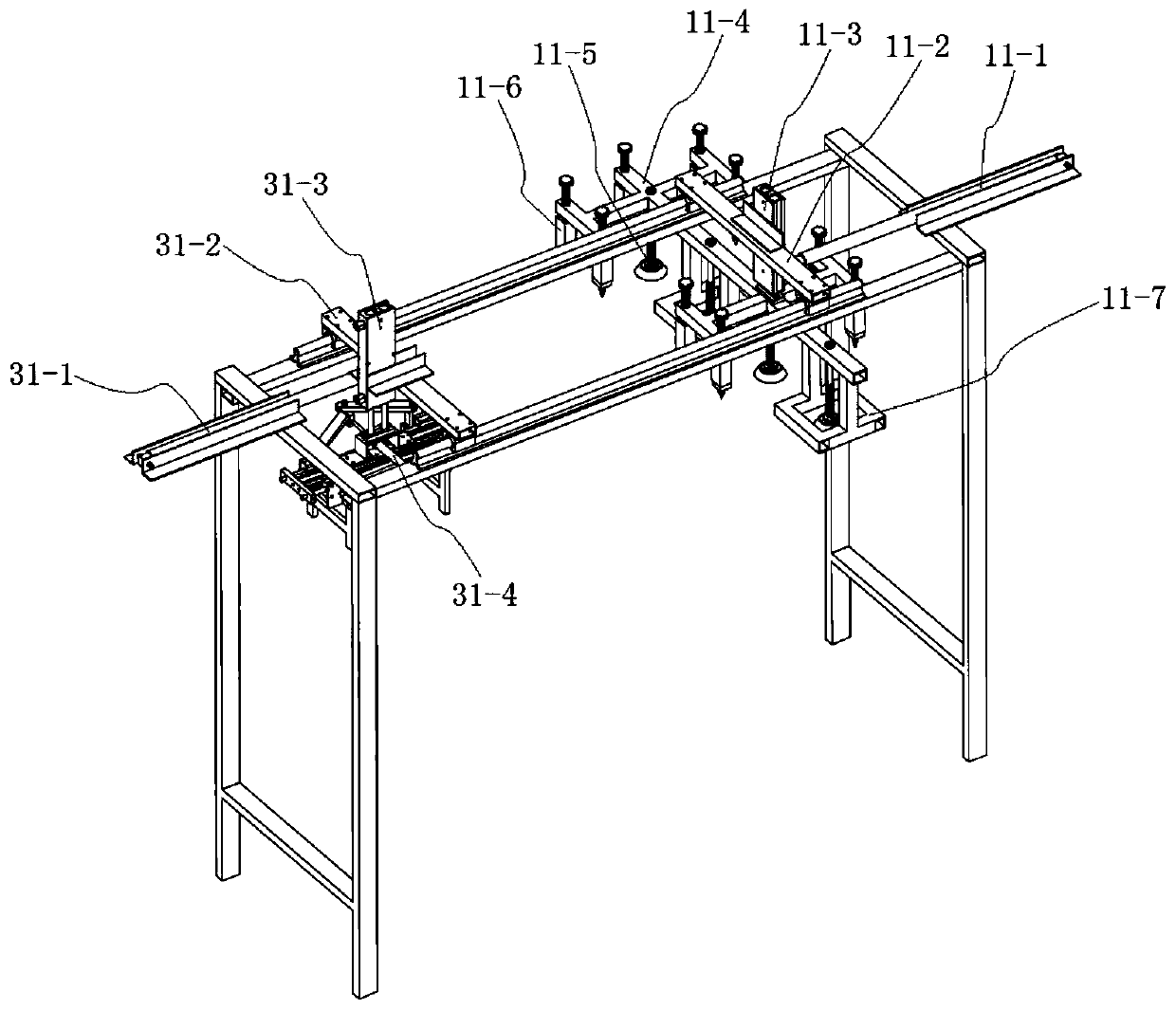

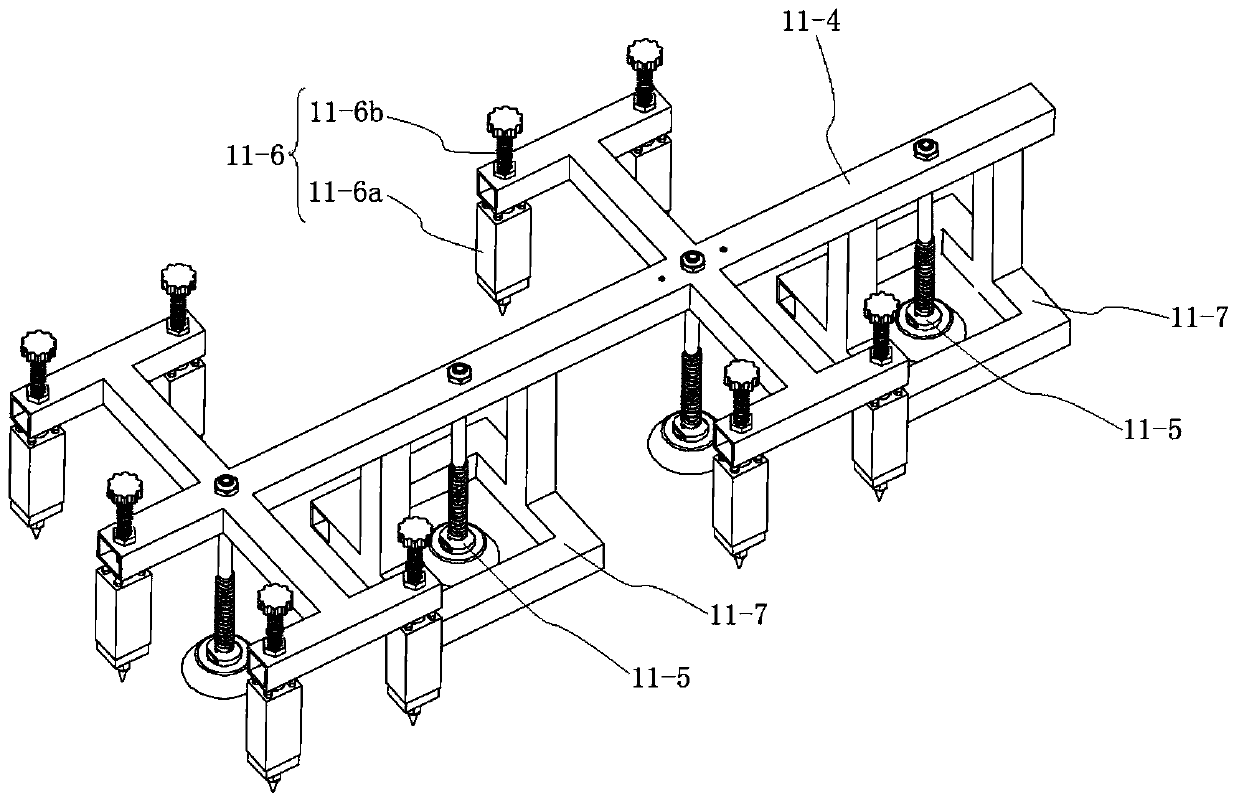

[0060] Such as Figure 1 to Figure 8 As shown, the packaging machine part includes a paper feeding station 100, a packaging forming station 200 and a grabbing and conveying station 300 arranged in sequence, wherein,

[0061] The paper loading station 100 is provided with a cardboard carrying device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com