A self-locking crimping terminal button connection method

A connection method and self-locking technology, which is applied in the direction of connection, conductive connection, clamping/spring connection, etc., can solve problems such as burn-in, crimping handle lack of fixation, poor contact, etc., to improve sensitivity and smoothness, Improved convenience and reliability, reduced rotational resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

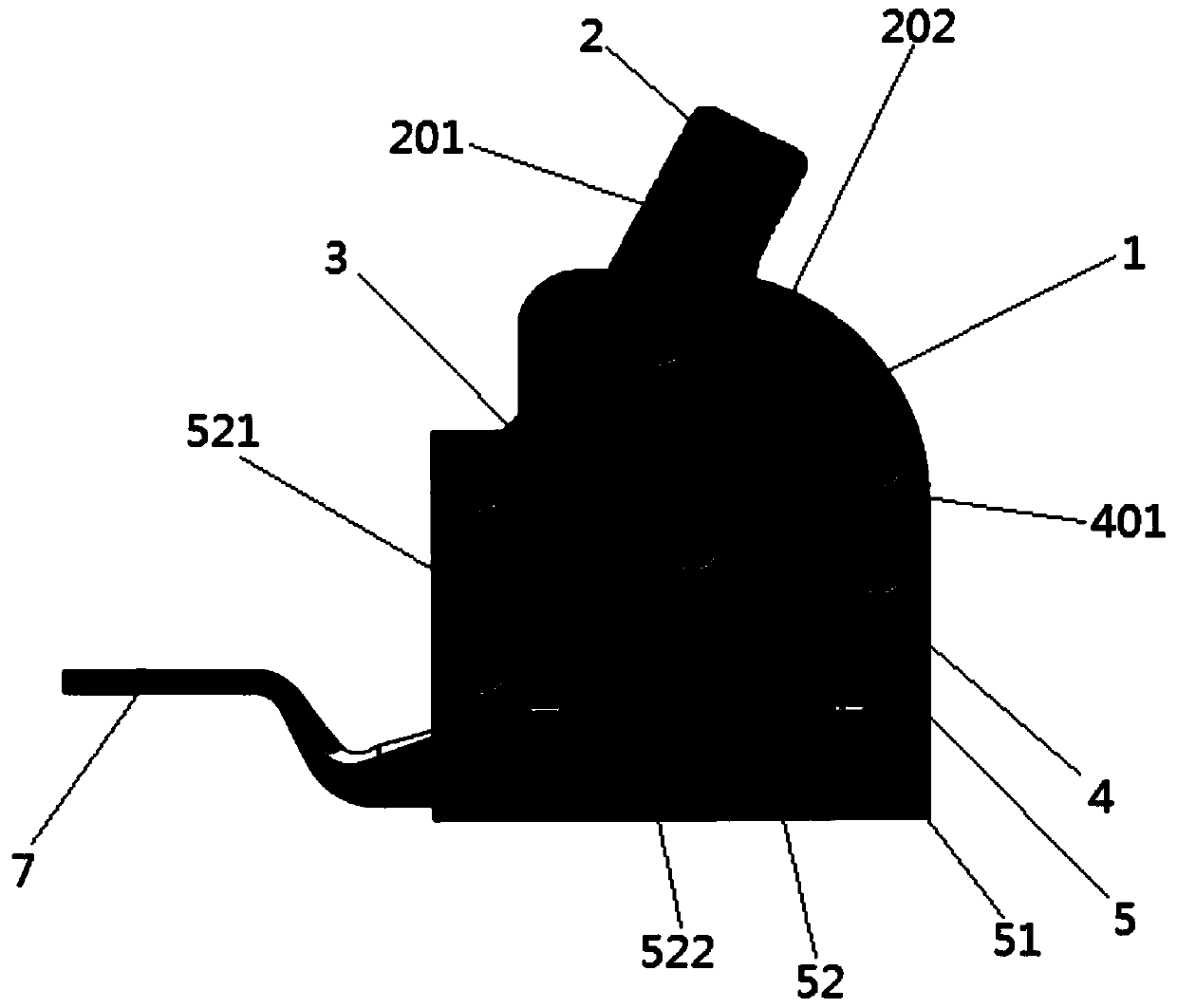

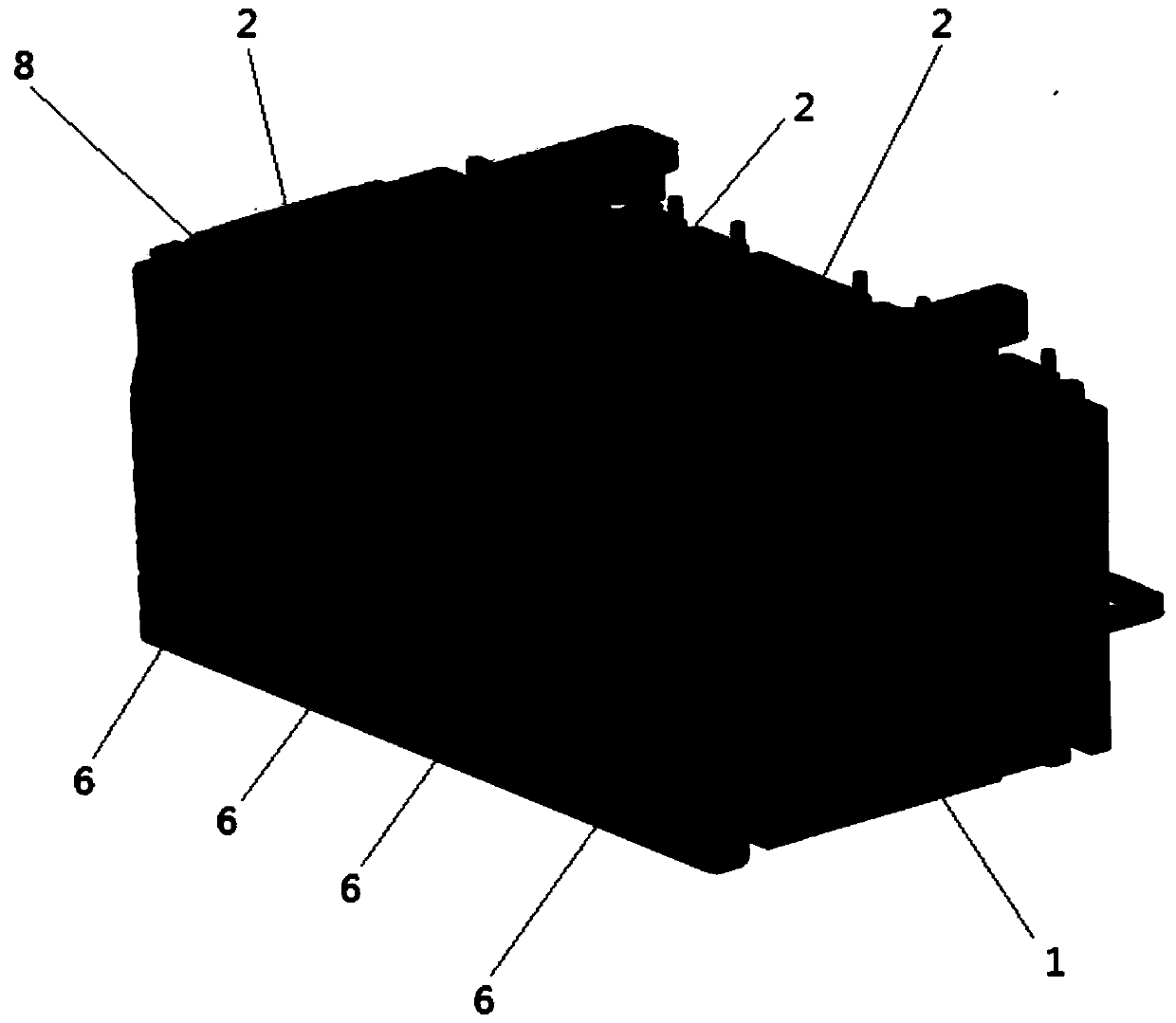

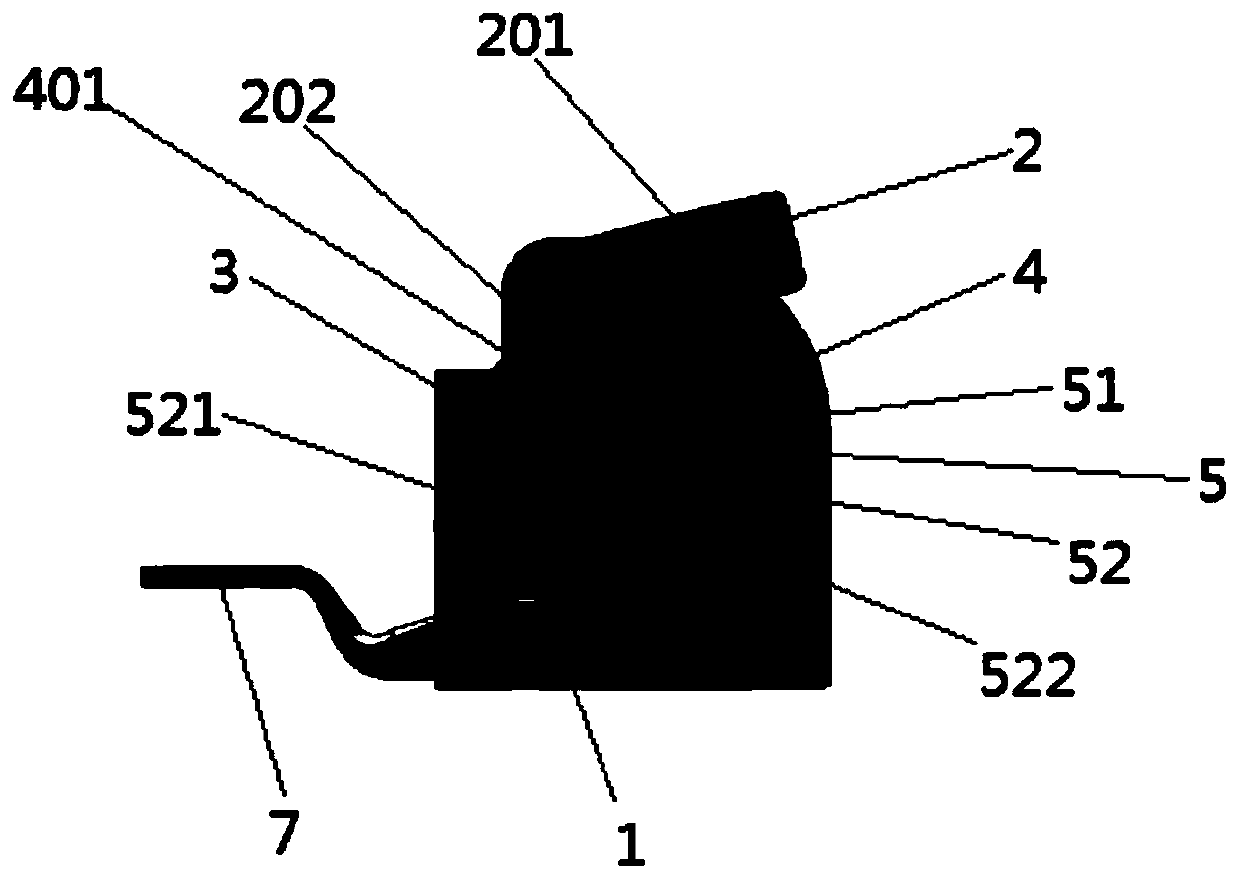

[0044] Embodiment 1: The shrapnel 5 is made of iron shrapnel; it enters the crimping state from the natural state, and the wire is inserted into the end button box from the round hole 6 at the bottom end, and after being tightly connected with the iron shrapnel, the operator depresses the crimping handle 2 . The crimping handle pawl 202 fixed by welding on the lower end of the crimping handle rod 201 drives the transmission ratchet 4 to rotate clockwise, thereby driving the elastic piece 5 to press down, and at the same time completes the connection and tightening of the wire. When entering the crimping state, the included angle between the first crimping piece 521 and the second crimping piece 522 is 10 degrees.

[0045]From the crimping state to the natural state, the crimping handle 2 is directly operated or the crimping handle 2 is operated by an external tool, and the crimping handle 2 is deflected upward. During the upward deflection of the crimping handle 2 , the crimpi...

Embodiment 2

[0047] Embodiment 2: The shrapnel 5 is made of copper shrapnel; from the crimping state into the natural state, directly operate the crimping handle 2 or operate the crimping handle 2 through an external tool to deflect the crimping handle 2 upward. During the upward deflection of the crimping handle 2 , the crimping handle pawl 202 fixed at the lower end of the crimping handle rod 201 drives the transmission ratchet 4 to rotate counterclockwise. At this time, the elastic piece 5 cancels the pressure on the access wire, so that the wire that has not been crimped is taken out from the round hole 6 at the lower end of the terminal box. When entering the natural state, the included angle between the first crimping piece 521 and the second crimping piece 522 is 30 degrees.

[0048] Entering the crimping state from the natural state, the wire is inserted into the terminal button box from the round hole 6 at the bottom end, and after being tightly connected with the iron shrapnel, t...

Embodiment 3

[0050] Embodiment 3: The shrapnel 5 is made of aluminum shrapnel; it enters the crimping state from the natural state, and the wire is inserted into the end button box from the round hole 6 at the bottom end, and after being tightly connected with the iron shrapnel, the operator presses down the crimping handle 2. The crimping handle pawl 202 fixed by welding on the lower end of the crimping handle rod 201 drives the transmission ratchet 4 to rotate clockwise, thereby driving the elastic piece 5 to press down, and at the same time completes the connection and tightening of the wire. When entering the crimping state, the included angle between the first crimping piece 521 and the second crimping piece 522 is 10 degrees.

[0051] From the crimping state to the natural state, the crimping handle 2 is directly operated or the crimping handle 2 is operated by an external tool, and the crimping handle 2 is deflected upward. During the upward deflection of the crimping handle 2 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com