cBN/diamond strength impact instrument control system

A control system, diamond technology, applied in the direction of testing the hardness of materials, can solve the problems of unstable testing of the control system, and achieve the effect of strengthening the protection function and visualization function, stable operation, and saving maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with embodiment.

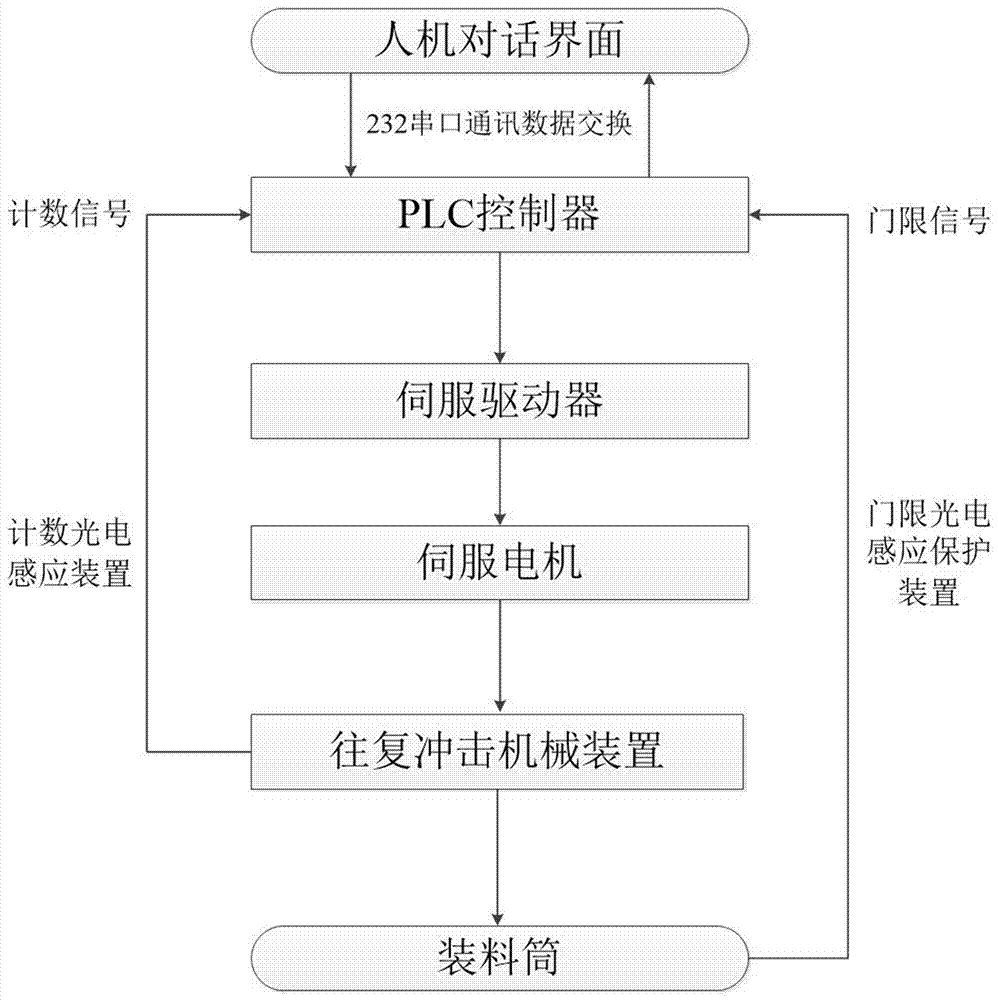

[0017] The invention is designed according to the working requirements of the quasi-ball milling method in which the ball and the sample reciprocate and vibrate along the axial direction of the cylinder. According to the requirements of control accuracy and performance, refer to figure 1 , the control system of the strength impact instrument of the present invention includes a man-machine dialogue interface system, a PLC controller, a servo driver, a servo motor, and a reciprocating impact mechanism, and the reciprocating impact mechanism drives the charging cylinder to perform a corresponding reciprocating impact movement, thereby measuring Impact strength of superhard materials.

[0018] Among them, the human-machine dialogue interface system is used as the upper computer, and communicates with the PLC controller through the 232 serial port data line. Accurate correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com