Double-row tapered roller bearing capable of bearing non-balance loads

A tapered roller bearing, non-balanced technology, applied in the field of bearing processing, can solve the problems of bearing stress concentration and bearing fatigue, and achieve the effect of reducing stress concentration, improving service life and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

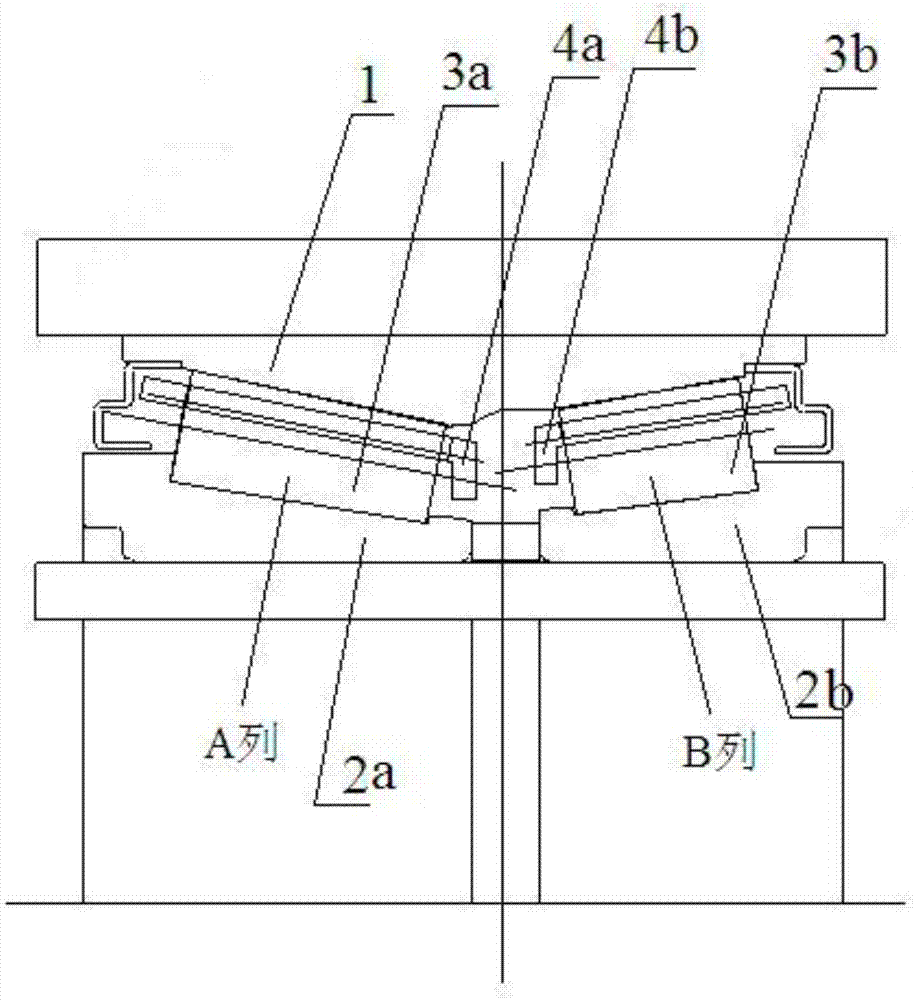

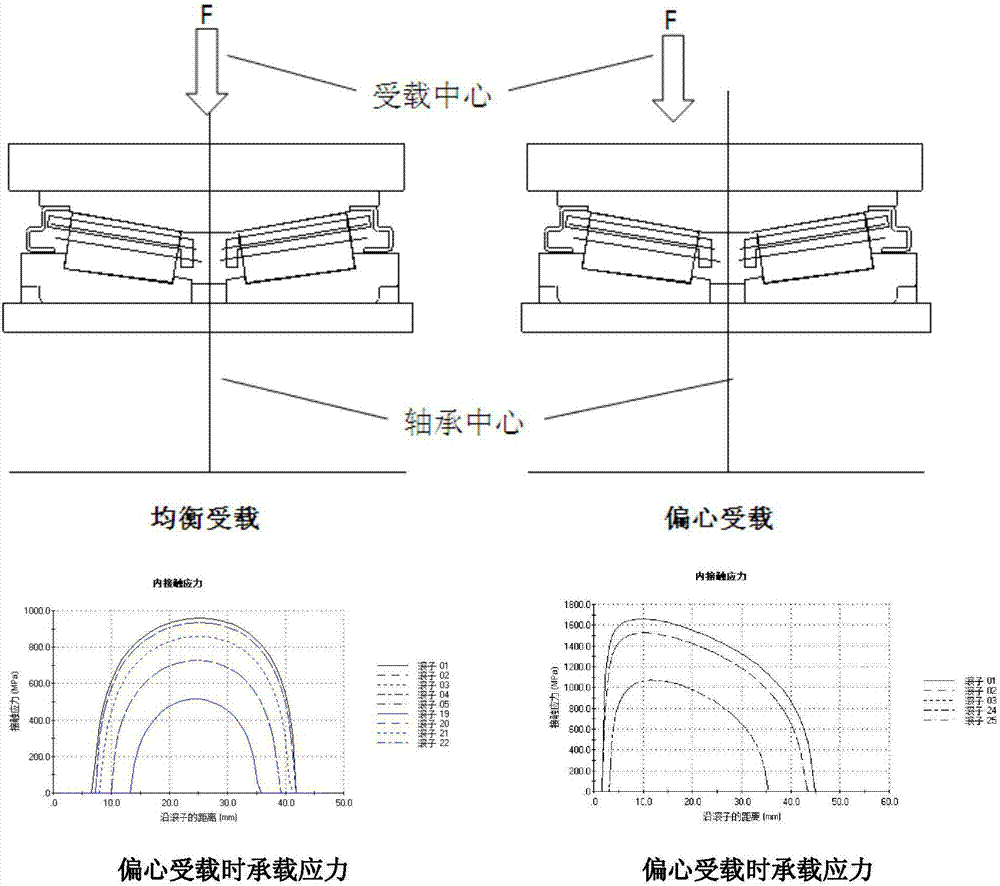

[0015] 1. For symmetrical bearings (that is, the parameters of the two rows of rolling elements are the same), when the bearing load center coincides with the bearing load center, as shown in the figure, the bearing load stress is uniform, which is an ideal stress condition. When the bearing load center is offset by a certain distance from the bearing load center (21.5mm in this example), the contact stress between the inner and outer ring raceways on the side of the load center and the rolling elements will be seriously unbalanced, which is higher than the ideal force. The stress of the condition is 75% higher, and the early fatigue of the bearing is caused by the stress concentration.

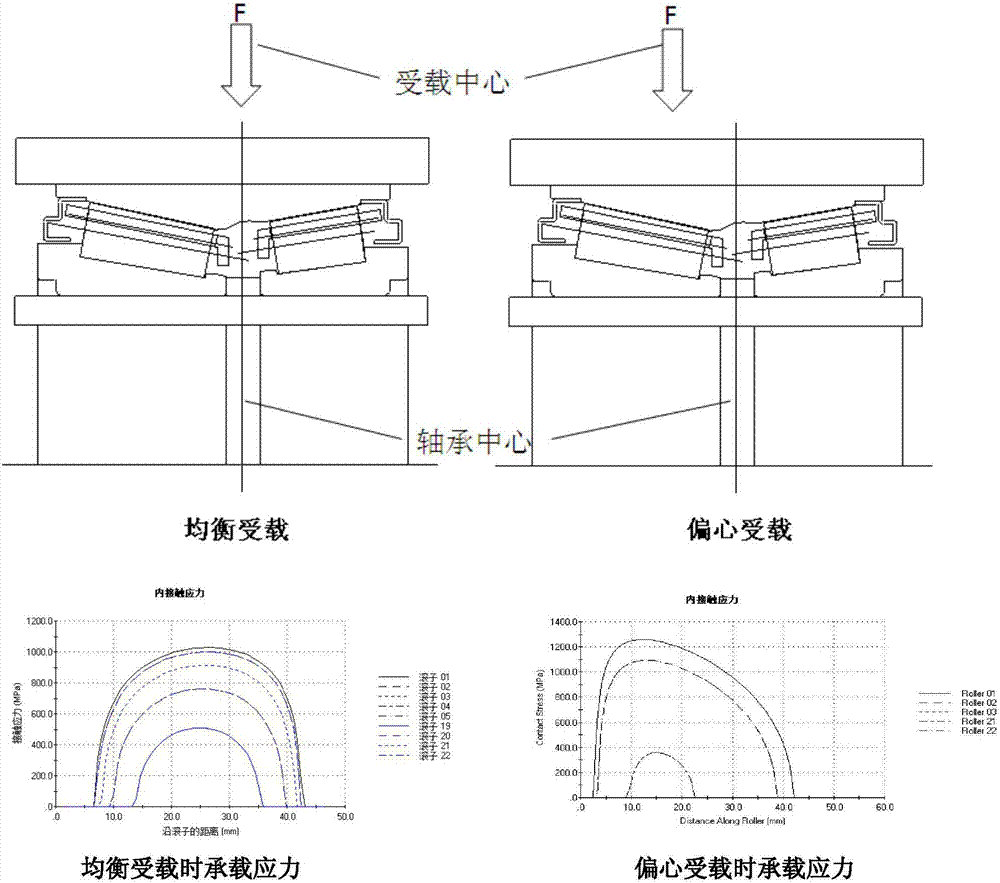

[0016] 2. For asymmetric bearings (that is, the parameters of the two rows of rolling elements are different), when the bearing load center coincides with the bearing load center, as shown in the figure, the bearing load stress is uniform, which is an ideal stress condition. When the bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com