Purifying and silencing two-in-one motorcycle silencer

A technology for mufflers and motorcycles, applied in mufflers, machines/engines, engine components, etc., can solve the problems of inability to attenuate, insufficient muffling, and inability to obtain muffling effects, achieving good muffling effects and improving safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

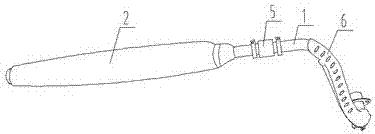

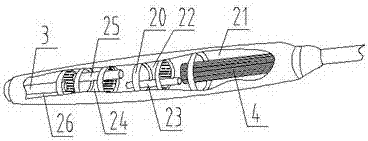

[0040] Embodiment one: see figure 1 , figure 2 As shown, a two-in-one motorcycle muffler for purification and noise reduction includes an exhaust pipe 1, a muffler cylinder 2 and a tailpipe 3, the inner space of the muffler cylinder 2 is a muffler chamber, and the muffler chamber is equipped with There are three baffles 20, namely the first baffle, the second baffle and the third baffle, and the first, second and third baffles divide the anechoic chamber into four chambers arranged in sequence from front to back Chamber 21, respectively the first, second, third and fourth chambers, wherein,

[0041] An installation hole is provided on the first partition, and the rear end of the exhaust pipe 1 is a rear catalyst 4, which extends into the second chamber through the installation hole.

[0042] A first mesh plate is arranged in the second chamber, and the first mesh plate, the second partition plate and the muffler cylinder 2 are surrounded to form a first resonant cavity 22, ...

Embodiment 2

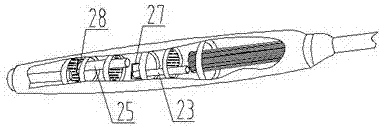

[0050] Embodiment two: if image 3 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that: the rear end cover of the first communicating pipe 23 is provided with a first muffler cover 27, and the rear end cover of the second communicating pipe 25 A second sound-absorbing cover 28 is provided, and a plurality of ventilation holes are provided on the first and second sound-absorbing covers.

Embodiment 3

[0051] Embodiment three: as Figure 4 , Figure 5 As shown, the structure of this embodiment is basically the same as that of Embodiment 2, the difference is that: the rear end cover of the muffler cylinder 2 is provided with a tail cover 7, and the connection between the muffler cylinder 2 and the tail cover 7 A drainage chamber is provided, and a drainage hole 8 is provided at the bottom of the drainage chamber.

[0052] In the present invention, resonant cavities are arranged in the second, third and fourth chambers, the noise elimination frequency range is wide, the noise elimination amount is sufficient, and certain noise peak frequencies can be attenuated to obtain better noise elimination effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com