Control system and method for axial tension degree of heat shrink tube

A technology of axial stretching and control system, which is applied in the field of control system of axial stretching degree, which can solve the problem that the degree of axial stretching degree cannot be monitored and controlled online, and the axial stretching degree of heat shrinkable tube products cannot be guaranteed, etc. problem, to achieve the effect of improving the quality of the finished product and maintaining the stability of the axial stretch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

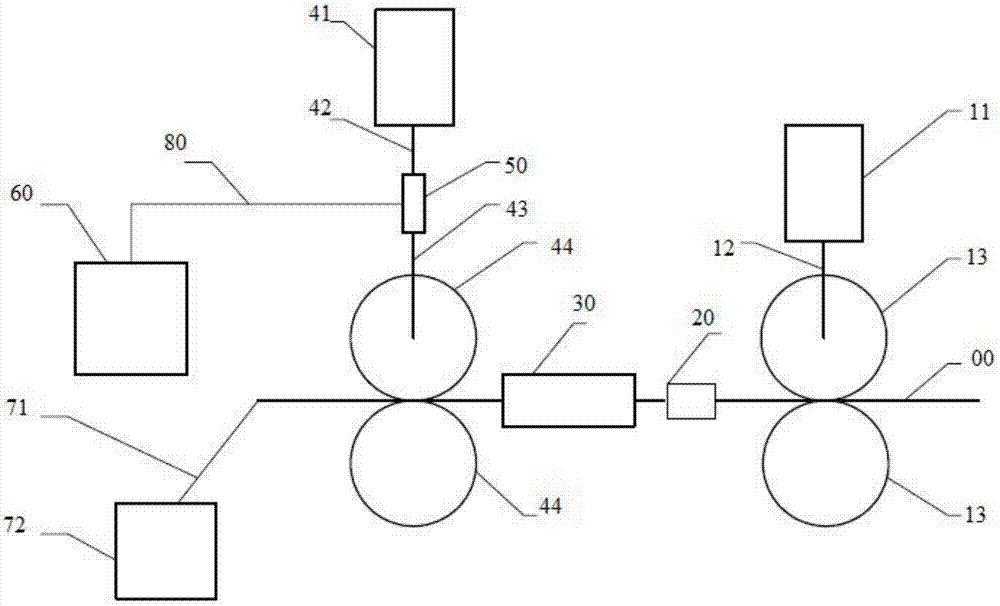

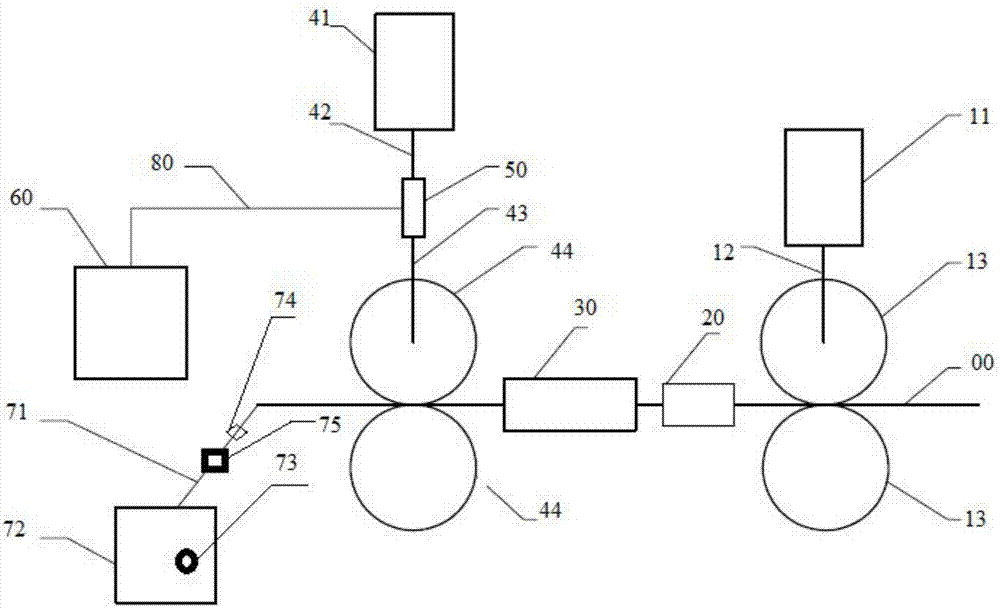

[0062] In order to more clearly illustrate the embodiments of the present invention or the technical solutions in the prior art, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings. Obviously, the accompanying drawings in the following description are only some embodiments of the present invention, and those skilled in the art can obtain other accompanying drawings based on these drawings and obtain other implementations.

[0063] In order to make the drawing concise, the parts related to the present invention are only schematically shown in each drawing, and they do not represent the actual structure of the product.

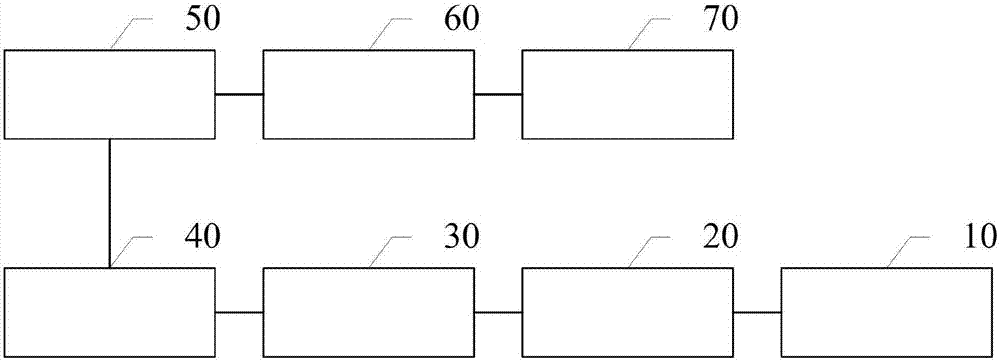

[0064] In the first embodiment, if figure 1 As shown, a control system for the axial stretch of the heat shrinkable tube 00 includes: a conveying roller set 10 for conveying the heat shrinkable tube 00, a heating furnace 20 for heating the heat shrinkable tube 00, The expansion mold 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com