Welding clamping method for automotive suspension control arm

A technology of automobile suspension and welding clip, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

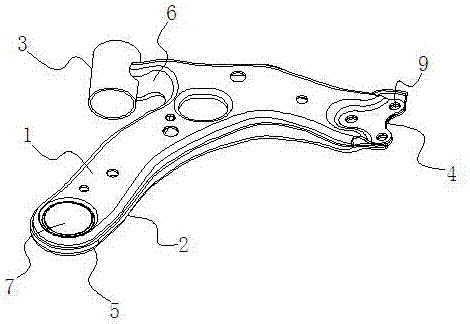

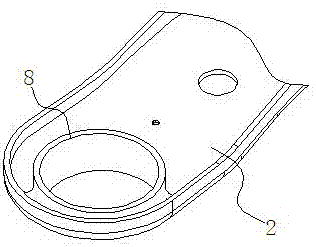

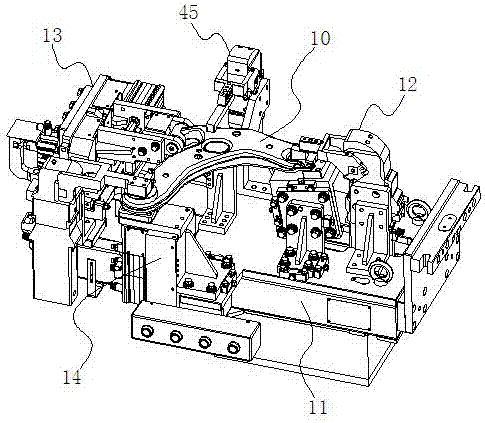

[0058] Example: such as image 3 and Figure 4 As shown, a welding and clamping method of an automobile suspension control arm 10, the welding method is to set a ball joint end clamping mechanism 12, a sleeve joint end clamping mechanism 13 and a ball stud on a working platform 11. End clamping mechanism 14, before welding, first utilize the ball joint end clamping mechanism 12 and the ball stud installation end clamping mechanism 14 to be positioned at the top cover 1 and the bottom at the ball joint end and the ball stud installation end. The cover 2 is clamped together, and then the sleeve 3 is pressed against the sleeve connection end by the clamping mechanism 13 of the sleeve connection end, and then welding is performed. In this embodiment, the clamping mechanism of the ball stud connecting end, the sleeve connecting end clamping mechanism and the ball stud mounting end clamping mechanism are set up to cooperate to perform clamping, so as to ensure the processing accura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com